SNL’s Rocket Sled Track Complex (RSTC), in Albuquerque, New Mexico, consists of the main Rocket Sled Track Facility and three explosive test Pads, which are used to test various explosives and rocket motors.

The Rocket Sled Track provides a controlled environment for high-velocity impact, aerodynamic, acceleration, and other related testing for both small and large test items. Tests can be designed to simulate unique scenarios and to provide the maximum data from each test. The facility provides a 10,000-foot track for testing items at very high speeds, and a 2,000-foot railroad gauge track for testing very large, heavy items at moderate speeds. The combination of ingenuity, experience, and instrumentation available at this facility makes it unique for research, test, and evaluation purposes.

Instrumentation

The Rocket Sled Track incorporates exceptional instrumentation capabilities, including telemetry, hardened on-board data recorders, hardwired data acquisition systems, high-speed quantitative imaging systems, and flash x-ray. These systems gather data from a variety of instruments and transducers. A vast array of non-contact, high-speed 2D and 3D imaging measurements are possible, and are described on our photometrics page. Data acquisition systems are capable of acquiring data at sample rates up to 1 MHz.

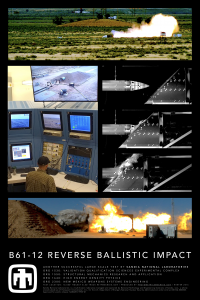

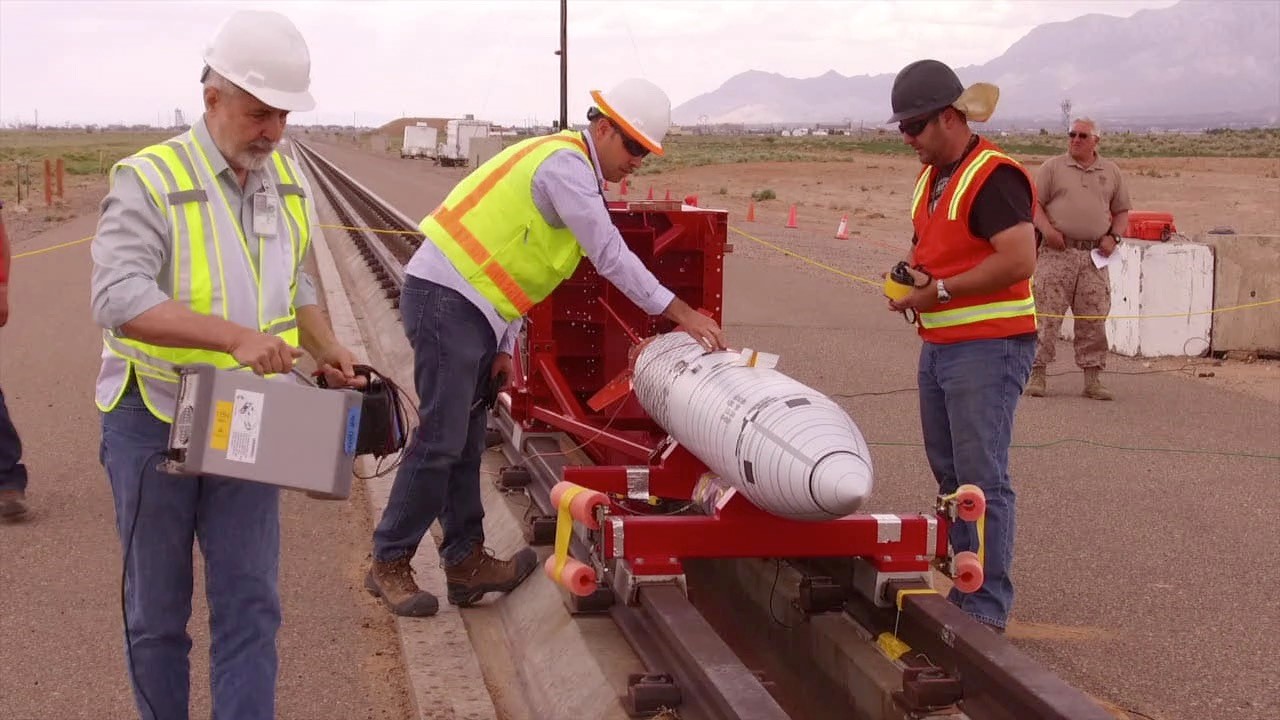

Forward and Reverse Ballistic Testing

Traditional sled tests accelerate a test item attached to a rocket sled into a stationary target (forward ballistic testing). Although this type of test more closely imitates the desired impact conditions, it typically limits the data acquisition capabilities, due to the use of on-board data recorders. Also, the coordination of forward ballistic tests can be complex (two sleds, water brakes, cable cutters, etc.). A reverse ballistic test, pioneered at the SNL Rocket Sled Track, accelerates the target into a stationary test item. This method allows a greater number of instrumentation channels at greater sample rates and higher reliability.

Acceleration Testing

The relationship between acceleration, velocity, and distance traveled by a test item can be simulated in a variety of ways. Positive and negative acceleration levels up to thousands of g are possible.

Aerodynamics Testing

Aerodynamic characteristics, as they relate to a test item’s shape, acceleration, velocity, and distance traveled, can be evaluated in a variety of ways, depending on evaluation goals. Onboard cameras and data recording systems are routinely used for this type of application.

Other Capabilities

The 10,000-ft Rocket Sled Track is also certified to handle:

- Weights up to 100,000 lbs (~100 feet per second)

- Velocities up to 6,000 ft/s (up to ~500 lbs)

- 500 lbs net explosive weight (NEW) detonation maximum

- Test unit unique contents

- Extensive diagnostics, including instrumentation (recorded on-board and off-board), photometrics, and flash X-ray

- Brake sleds and split sleds (can release test units and eject test articles)

- Detonation of up to 250 pounds of high explosives (HE)

Blast Tubes

- Moderate Hazard Facility

- 3- to 12-foot-diameter pipes, configurable in a variety of lengths and diameters to meet customer needs

- 25 to 120+ ms pulse

- Test items containing rad, HE/IHE

- Up to 250 lbs NEW detonation

- Test unit hazards are evaluated on an individual basis, which includes some or all of the following:

- Explosives (including test unit main charges)

- Radioactive materials

- Beryllium

- Fires

- Rocket motors

- Classified materials

- Current Tube Configurations

- 120-foot tube length, 20-50 ms pulse duration

- 300-foot tube length, 100 ms pulse duration

- Instrumentation/Photometric Support

- 192-channel instrumentation trailer

- Quantitative High-speed Imaging

Downloadable posters