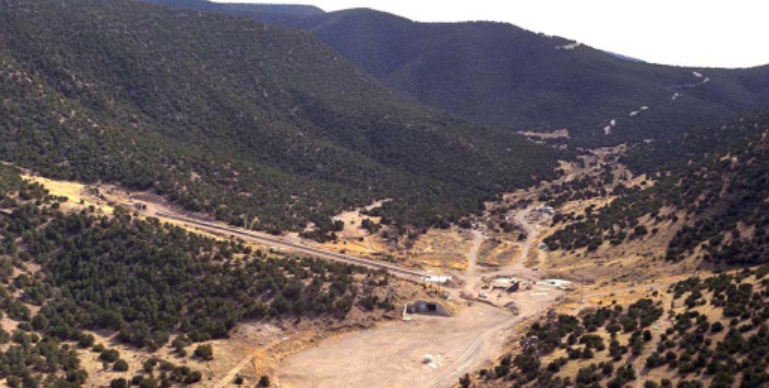

Sandia National Laboratories’ Aerial Cable Facility in Albuquerque, New Mexico, provides a unique capability to precisely simulate a wide variety of environments in a highly instrumented test arena.

Primary among these environments are drop and high-velocity impact testing, suspension of large items hundreds of feet above the ground, and simulated free flight along an aerial cable. The facility has four primary cable systems that span two ridges over a mountain canyon. Each cable is approximately 5,000 feet long and has endpoint anchors about 1,000 feet above the valley floor. At the center of each cable span is a flat test arena about 300 feet in diameter. The ACF includes secluded, secure, open spaces in which to conduct a variety of tests.

Drop and Pulldown

Each cable can be raised and lowered to lift items to varying positions and orientations above the ground. Items as heavy as 75,000 pounds can be lifted and dropped from about 100 feet, while lighter items can be raised to 650 feet (maximum).

The facility can perform impact testing that offers:

- High- or low-velocity

- Guided and unguided drop testing

- Hard or soft targets

- Penetration events

- Items containing radioactive materials

- Up to 1,000 pounds of high explosives

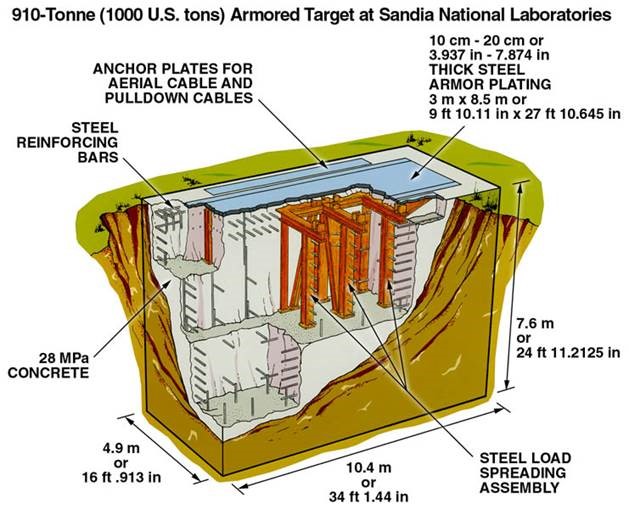

Hard Target

The hard target at the ACF was developed in the 1980s to satisfy the requirement of an “unyielding surface” for testing nuclear transportation packages (see diagram below). The target has a mass greater than 900,000 kg and, with materials such as concrete and armor steel plating, is designed not to fail after repeated impacts.

Soft Targets & Custom Targets

- Soil

- Pumice-filled concrete

- Relatively low target strengths

Unguided Drop Tests

- Simple gravity drops used for container certifications

- Typically low drop height (< 40 feet)

- Thermal conditioning

- High-speed imaging to provide diagnostics, impact parameters

- Can accommodate highly instrumented test articles

- Puncture tests

- Custom probes can be fabricated and installed on hard target

Guided Drop Tests

- Can achieve velocities up to ~150 fps

- Thermal conditioning

- High-speed imaging to provide diagnostics, impact parameters

- Can accommodate highly instrumented test articles

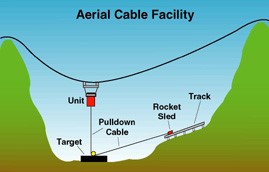

Pulldown Tests

- Utilizes rocket sled track and tow rope to pull test article towards target

- Test unit suspended from aerial cable system

- Tow ropes pass through sheaves on the target, connecting the test unit to the rocket sled

- Upon unit release from cable system, the rocket sled tows the test unit downward

- Tow ropes are severed just above target so that the test unit impacts in free flight

- Rocket sled is captured by catch box at top of track

- Can achieve velocities up to ~1000 fps

- Thermal conditioning

- High-speed imaging to provide diagnostics, impact parameters

- Typically requires on-board data recorder in test article

Rocket Rail

- I-Beam rail designed as “miniature” inverted sled track

- Can be elevated on back end to perform laydown-like impacts

- Capable of taking full weapon systems

- Used extensively in simulating B61 laydown environments

- Thermal conditioning

- High-speed imaging to provide diagnostics, impact parameters

- Can accommodate highly instrumented test articles

The ACF can conduct rocket-assisted impact tests, with impact speeds up to 1,200 feet per second. Target impact angles of 30 to 90 degrees can be achieved, and the angle of attack can be tightly controlled and measured. The ACF can also be configured to accommodate a wide variety of additional testing scenarios, including artillery firing and scoring, countermeasures and warning systems evaluation, and explosives testing. A 200 x 225-foot net can provide a soft-catch method for items dropped from altitudes.

Trolley and Simulated Free Flight

A cable car or trolley can be rolled or rocket-propelled on a cable to flight velocity to serve as a test target (simulated aircraft for missile systems) or test platform (aircraft onboard systems). Sandia engineers can design and build trolleys to meet specific customer needs, or customer-furnished hardware may be integrated for use as a cable car. Proven technology exists for vehicles and velocities in excess of 300 knots.

Telemetry control and monitoring of the vehicle and onboard systems is available. Test windows may vary between 10 seconds and one minute, depending on the vehicle velocity.

Instrumentation

The ACF has exceptional instrumentation capabilities. The facility uses photometrics, laser trackers, telemetry, and hardwire systems to gather data from a variety of instruments and transducers. Time-space-position information (TSPI) can be acquired at up to a 1-KHz rate, with accuracy within one foot. Transducer data may be sampled at up to 1.25 MHz.

High-speed video and film cameras running up to 40,000+ frames per second are also available. These capabilities can meet a wide variety of customer needs for a single test or a series of test and evaluation scenarios.

Downloadable posters