This website provides information about Sandia’s Laboratory Directed Research and Development (LDRD) project that investigates and develops micro-chemical sensors for in-situ monitoring of subsurface contaminants.

Description

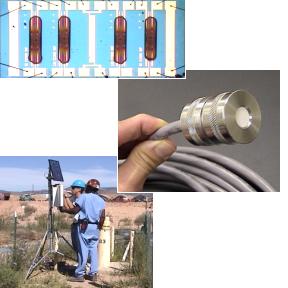

Traditional methods for monitoring sites that may be contaminated with toxic chemicals can be expensive, time consuming, and misrepresentative of in-situ conditions. A few in-situ chemical monitoring systems exist, but they do not attempt to quantify or characterize the contaminant (e.g., location, composition, etc.). This website presents the development of a microsensor monitoring system that can be used to monitor and characterize volatile organic compounds (VOCs) in the subsurface. A microchemical sensor that employs an array of chemiresistors is packaged in a unique, waterproof housing (early version made of PEEK and later version made of stainless steel) that is designed to protect the sensor from harsh subsurface environments, including completely water-saturated conditions. The array of sensors is calibrated to provide “training sets” for pattern recognition of various chemicals and chemical mixtures. The sensors and packaging has been tested in the laboratory and field, and unique characterization methods are being developed that utilize contaminant transport models and time-dependent, in-situ sensor data. Additional characterization methods that can be employed during soil remediation methods such as soil venting and air sparging are also being tested.

The sensor system consists of an array of miniature sensors, called chemiresistors, that can detect volatile organic compounds (VOCs). Each chemiresistor is fabricated by mixing a commercial polymer dissolved in a solvent with conductive carbon particles. The ink-like fluid is deposited and dried on wire-like electrodes on a specially designed integrated circuit. When VOCs are present, the chemicals absorb into the polymers, causing them to swell. The swelling changes the electrical resistance that can then be measured and recorded. The amount of swelling corresponds to the concentration of the chemical vapor in contact with the polymers. The process is reversible, and the polymers will shrink once the chemical is removed, reverting the resistance to its original state. See an illustration of this process.

This printable Fact Sheet provides information on the problem, objectives, and collaborative opportunities for this project.

Review a PDF containing photos of the sensor package and water immersion experiments.

Background and Objectives

Tens of thousands of sites containing toxic chemical spills, leaking underground storage tanks, and chemical waste dumps require accurate characterization and long-term monitoring to reduce health and environmental risks and ensure public safety (Superfund Program). In addition, over two million underground storage tanks containing hazardous (and often volatile) contaminants are being regulated by the EPA (U.S. EPA, 1992), and the tanks require some form of monitoring to detect leaks from the tanks and pipe network. However, current methods are costly and time-intensive, and limitations in sampling and analytical techniques exist. Looney and Falta (2000, Ch. 4) report that the U.S. Department of Energy (DOE) Savannah River Site requires manual collection of nearly 40,000 groundwater samples per year, which can cost between $100 to $1,000 per sample for off-site analysis. Wilson et al. (1995, Ch. 36) report that as much as 80% of the costs associated with site characterization and cleanup of a Superfund site can be attributed to laboratory analyses. In addition, the integrity of off-site analyses can be compromised during sample collection, transport, and storage. Clearly, a need exists for accurate, inexpensive, real-time, in-situ analyses using robust sensors that can be remotely operated.

Although a number of chemical sensors are commercially available for field measurements of chemical species (e.g., portable gas chromatographs, surface-wave acoustic sensors, optical instruments, etc.), few have been adapted for use in geologic environments for long-term monitoring or remediation applications. The purpose of this LDRD project is to identify and develop sensor technologies that can be used in these long-term geologic applications. As a result, technologies such as electrical-resistivity monitoring and ground-penetrating radar are not considered here because they require significant amounts of manual labor and supervision to operate. Instead, we seek low-cost sensors that can be emplaced and operated with minimal supervision, which yield continuous real-time monitoring capabilities.

The particular focus of this project is limited to the detection and monitoring of volatile organic compounds (VOCs). These include compounds such as aromatic hydrocarbons (e.g., benzene, toluene, xylene), halogenated hydrocarbons (e.g., trichloroethylene (TCE), carbon tetrachloride (CT)), and aliphatic hydrocarbons (e.g., hexane, octane). As a result, sensors and technologies that detect gas-phase constituents in the vadose zone are emphasized because VOCs are most conveniently and economically monitored in the gas phase. However, the ability to detect VOCs in groundwater and saturated environments is also an important objective of the LDRD project.

This website presents the development of microchemical sensors that can be used to provide real-time monitoring and characterization of volatile organic compounds (VOCs) in situ, which can provide cheaper and more reliable information.

Specific objectives for this LDRD project include the following:

- Develop microsensors and integrated monitoring system that provide real-time, in-situ analyses of VOCs.

- Develop polymer absorption sensors for in-situ applications and investigate microsystems with integrated pre-concentrator for enhanced detection capabilities.

- Develop robust packaging system that allows the sensor to operate in wet or dry subsurface environments.

- Develop novel characterization methods using in-situ data and predictive process models of contaminant transport.

- Understand impacts of subsurface environment (e.g., heterogeneities, moisture content, temperature) on sensor data and interpretation.

- Link to web page with real-time in-situ monitoring data from Sandia’s Chemical Waste Landfill monitoring stations

- 05-31-01: Movie (8.84 Mb) of initial test of sensor at Chemical Waste Landfill (SNL)

- 09-07-01: Movie (34 Mb) of field deployment of chemiresistor sensor package at Chemical Waste Landfill (SNL)

- 09-19-01 to 09-25-01: Summary report (PDF file 587 KB) of 55-gallon drum test at the Hazmat Spill Center at the Nevada Test Site to test the sensor during a TCE spill and air-venting remediation operation.

- SAND2005-0336: SAND report of FY04 field tests at Edwards Air Force Base, CA (PDF file 1.4 MB).

- SAND2002-4135: SAND report of FY02 field tests at Edwards Air Force Base, CA (PDF file 2 MB).

- SAND2003-0799: SAND report of FY02 field tests of the chemiresistor and surface-acoustic-wave sensors at the Nevada Test Site (PDF file 3.5 MB).

Ho, C.K., M.W. Jenkins, R.C. Hughes, and P.G. Reynolds, “Microchemical Sensor Package for In-Situ Monitoring,” Sandia National Laboratories Technical Advance SD-6976, 8/2001.

Ho, C.K., “Characterization Methods for Real-Time In-Situ Sensing of Volatile Contaminants,” Sandia National Laboratories Technical Advance SD-6894, 4/2001.

Ho, C.K., “Designs and Deposition Methods for Polymer-Based Microchemical Sensors, Sandia National Laboratories Technical Advance SD-7095, 1/2002.

Ho, C.K., “Automated Monitoring and Remediation System for Volatile Subsurface Contaminants, Sandia National Laboratories Technical Advance SD-7097, 1/2002.

Looney, B.B. and R.W. Falta (editors), 2000, Vadose Zone Science and Technology Solutions, Battelle Press, Columbus, OH, 1540 pp.

U.S. Environmental Protection Agency (EPA), 1992, Measurement and Analysis of Adsistor and Figaro Gas Sensors Used for Underground Storage Tank Leak Detection, Report #EPA/600/R-92/219.

Wilson, L.G., L.G. Everett, and S.J. Cullen (editors), 1995, Handbook of Vadose Zone Characterization & Monitoring, CRC Press, Boca Raton, FL.

The technologies described in this web site are available for licensing. A summary of the intellectual property available for licensing can be found in the following Word file:

For information regarding the content of the intellectual property, please contact Cliff Ho, (505) 844-2384, ckho@sandia.gov. For information regarding licensing, please contact Tom Westervelt, rtweste@sandia.gov.

We are interested in teaming with various agencies, institutions, and companies to further develop, deploy, and refine our chemiresistor technology. The table below lists contacts that have expressed interest in evaluating, testing, and deploying the in-situ chemiresistor sensor technology. We would appreciate hearing from you if you would also like to team with us.

| Government | Industry | Research |

| Edwards Air Force Base Nevada Test Site Sandia National Laboratories | Lighthouse Worldwide Solutions Eco-Remediation, Inc. Team Specialty Products | Brigham Young University |