ADDSec: Artificial Diversity and Defense Security

Industrial control-system environments, such as the electric power grid, oil and natural gas refineries and water pipelines, continue to use predictable communication paths, static configurations and unpatched software, all of which benefit adversaries.

Sandia has developed a technology that automatically detects and responds to threats within critical infrastructure environments in real time. The detection approach uses a set of machine learning algorithms that recognizes anomalous behavior and then classifies those anomalies into categories of attacks. The response approach uses software-defined networking to randomize IP addresses and application port numbers, invalidating the attacker’s knowledge of the network and preventing successful deployment of attacks.

CHIRP: Cloud Hypervisor-forensics and Incident Response Platform

CHIRP gives cyber analysts a holistic view of Cloud systems, providing the tools required to collect forensic artifacts, evidence and incident response materials in real time without disturbing the user environment or alerting the intruder. Using CHIRP, analysts can pinpoint suspicious activities, track and record attacker actions for forensic analysis and retrieve materials transparently from the targeted machines automatically or on-demand. The features of CHIRP also may be used by responders to disrupt malicious copying, deleting, obfuscating, encrypting and relocating of data in a Cloud environment.

MIRaGE: Multiscale Inverse Rapid Group-theory for Engineered-metamaterials

Experimental approaches (perhaps intuitive ones) good luck and considerable calculation could eventually lead a designer to a metamaterial with suitable properties for particular tasks, but this search can be a tedious, hit-or-miss process.

MIRaGE, a unique software created by Sandia under a Defense Advanced Research Projects Agency contract, uses knowledge developed from molecular spectroscopy that determines how the symmetry of a natural molecule affects its optical behavior and properties. This enables design of a metamaterial with comparable properties. By utilizing the user-friendly MIRaGE interface to specify properties, a designer might accomplish in minutes what might otherwise take months or years.

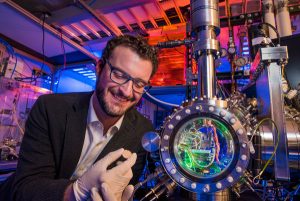

NEDs: High-Performance Nanoantenna-Enabled Detectors

Nanoantenna-Enabled Detectors offer a method to reduce noise interference to incoming infrared signals by factors of 10 to 100. Moreover, commercial long-wave infrared detectors only “see” around 25% of the thermal radiation that hits them. This value is improved by NEDs to well over 50%. Thus, the signal-to-noise ratio of a camera based on these detectors would gain two to three times on signal while simultaneously allowing much clearer pictures.

The technology incorporates a nanoantenna — a subwavelength metal pattern — on the top surface of the detector, which concentrates the light and lets it use a detector layer that is just a fraction of a micron. This distinguishes the method from the 5- to 10-micron thickness of traditional detectors, which creates more noise in recorded images and pixel-to-pixel crosstalk in focal plane arrays, causing image blurring.

Sandia’s work overcomes both these issues in a single device. While potentially useful across the spectrum, this architecture is particularly useful at infrared wavelengths, where current technology has run into a roadblock for noise reduction, quantum efficiency and crosstalk: all key metrics for infrared image quality.

Special Recognition: Green Tech

GOLD: SiC-based Monolithic Transistor-Rectifier Semiconductor Switch

Sandia, in collaboration with GeneSiC Semiconductor, has developed the industry’s first commercially available silicon-carbide, transistor rectifier on a single chip. The monolithic transistor rectifier switch allows power-electronic systems to operate at a four-times-higher switching frequency, thus allowing designs for proportionally smaller magnetic components like inductors and transformers, which are often the bulkiest components of power-electronics hardware.

Other significant advantages include more efficient bidirectional performance, lower switching and conduction losses, reduced cooling requirements, ease of paralleling devices and cost benefits. The invention also reduces the total amount of silicon carbide used by up to 50%. In power conversion terms, higher switching frequency means smaller size and lower cost.

Widespread use of this novel SiC device might result in saving more than 20% of the world’s electricity costs and 40% more energy savings. It could spur innovations in a wide range of electricity-using devices, including electric vehicles, battery chargers, industrial/medical power supplies, data centers, electric ships, transportation electrification, photovoltaic inverters, wind energy converters and other utility-scale power electronics systems, such as high-voltage, direct-current transmission and flexible alternating current transmission systems.

SiC-based Switch: Watch the video.

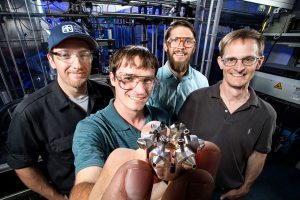

SILVER: Ducted Fuel Injection

Sandia researchers showed that ducted fuel injection can curtail the soot emissions from a diesel engine by 50% to 100% depending on the engine’s speed and power level.

DFI is a conceptually simple technology, can be constructed from low-cost materials and is conceivably retrofittable onto existing engines. Like a Bunsen burner, the technique premixes fuel and intake gas using a small cylindrical duct around each fuel spray inside the combustion chamber. The low soot emissions of DFI also enable the use of more cost-effective approaches to control nitrogen oxide emissions, solving a long-standing emissions challenge for diesel engines. This could lead to substantial reductions in the size, cost, complexity and efficiency penalties of diesel exhaust-gas aftertreatment systems.

Furthermore, while DFI is fully compatible with current diesel fuel, blending with oxygenated renewable fuels like biodiesel can enhance its soot-reduction performance by another order of magnitude, while simultaneously increasing sustainability.

Ducted Fuel Injection: Watch the video.

Special Recognition: Market Disruptor – Products

BRONZE: Stable Nanocrystalline Metal Alloy Coatings with Ultra-Low Wear

Noble metal coatings and thin films are used in a wide range of products, from cell phones to slip-rings on wind turbines and the Mars Rovers. The lifetimes of all these devices depends to a large degree on the ability of the coating material to resist wear.

Sandia researchers have developed a platinum-based alloy that is extremely wear-resistant, using a technique called grain boundary segregation to create highly stable nanocrystallinity of a minority constituent — in this case, gold.

Compared with hard gold alloy coatings, platinum coatings demonstrate remarkably higher wear-resistance. This formerly unrealized mechanical performance is attributed to extraordinary thermodynamic stability of grain boundaries, which are more effective barriers to deformation. Platinum-gold coated electrical contacts demonstrate order-of-magnitude improvements in strength, thermal stability and wear resistance compared to hard gold alloy coatings and films.

Stable Nanocrystalline Metal Alloy Coating: Watch the video.