The U.S. Army is responsible for coordinating the demilitarization of all outdated and retired munitions across all branches of the military. For more than 14 years, Sandia has been designing, developing, and delivering advanced demilitarization systems to the Army. These systems are designed to be robust to a wide variety of failure modes, making them safe and secure, and allowing people to be removed from the process, saving lives

Need

More than 300,000 tons of rounds are currently in a stockpile waiting to be demilitarized, some dating back to World War II. This amount is increasing by about 70,000 to 100,000 tons per year. These munitions have a high degree of variability resulting from production operations, aging in storage, and handling making them volatile and dangerous. Historically, these munitions were disassembled by humans.

Solution

Having successfully solved a similar problem for the Department of Energy with its Automated Gas Generator Disassembly System work cell, Sandia was able to quickly adapt its technology and system integration capability to create a prototype system for the Army that would disassemble 40-mm fixed-round munitions. Within nine months, Sandia designed, developed, delivered, and demonstrated a complex prototype system at the McAlester Army Ammunition Plant in Oklahoma.

Features

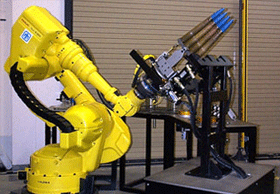

The system consists of an off-the-shelf articulated robot arm, force feedback control, machine vision, custom tooling, and an operator-driven graphical user interface (GUI) to disassemble the round and separate the component parts for reclamation. Sandia’s approach seamlessly integrated many processes into a highly complex disassembly operation that was designed for maximum safety and system effectiveness.

Applications

This research led to the design of a flexible automated pilot plant. A simulation of the pilot plant disassembly process enabled us to perform timing studies, observe layouts, and help estimate project costs. In the flexible automation pilot plant, robots are used to open and remove munitions from containers. The challenge is in the variations found in containers due to transportation and handling damage, making it difficult to access and remove munitions from the containers. This required us to integrate our advanced vision and perception systems and dexterous manipulation capabilities to solve the problem. Preliminary studies show the system can process one million rounds in one year working two 8-hour shifts per day.

Long-term flexibility was built in to the system: once all 40-mm fixed-round munitions have been disassembled (there are approximately 3 million currently in stockpile), the system can be modified to handle other munitions by reusing the same equipment. With minor tooling and software changes, the system will be able to handle the disassembly of a range of munitions from 30-mm to 120-mm fixed-round munitions.