Linear Transformer Driver

New Paradigm in Pulsed Power Technology

Most of the modern high-current high-voltage pulsed power generators require several stages of pulse conditioning (pulse forming) to convert the multimicrosecond pulses of the Marx generator output to the 40–300-ns pulses required by a number of applications including X-ray radiography, pulsed high current linear accelerators, Z-pinch, isentropic compression, and inertial fusion energy drivers. This makes the devices large, cumbersome to operate, and expensive.

Sandia National Laboratories, in collaboration with a number of other institutions, is developing a new paradigm in pulsed power technology: the linear transformer driver (LTD) technology. This technological approach can provide very compact devices that can deliver very fast high-current and high-voltage pulses. The output pulse rise time and width can be easily tailored to the specific application needs. Trains of a large number of high-current pulses can be produced with variable interpulse separation from nanoseconds to milliseconds.

MYKONOS II LTD voltage adder

Most importantly, these devices can be rep-rated to frequencies only limited by the capacitor specifications (usually 10 Hz). Their footprint, as compared with current day pulsed power accelerators, is considerably smaller since LTD do not require large oil and deionized water tanks. This makes them ideally suited for applications that require portability.

In the following paper, we present Sandia National Laboratories’ broad spectrum of developmental effort to design, construct and extensively validate the Linear Transformer Driver pulsed power technology. Learn more: High-Current Linear Transformer Driver Development at Sandia National Laboratories (MG Mazarakis, et al.)

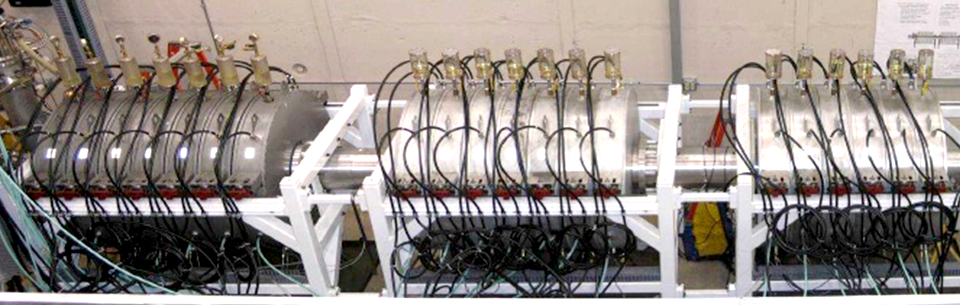

Ursa Minor is a 2.5 MeV LTD

Ursa Minor

- Based on the 1 MV system developed by the Institute for High CurrentElectronics (Tomsk, Russia)

- Upgraded from 7 to 21-Cavities and commissioned in 2011

- Cavities coupled to load with a magnetically insulated transmission line (MITL)

- 10 parallel bricks in each cavity

- Total of 210 switches and 420 capacitors