Tina Nenoff tailored molecular sponges to pull radioactive ions from nuclear waste.

Tina Nenoff learned to ski when she was about 10 while visiting relatives in Quebec. Despite the unrelenting cold and icy snow, she fell in love with the thrill and challenge. Similarly, a fantastic high school teacher sparked her interest in chemistry. Mrs. Tomcufcik was excited about the science and zestfully spread her enthusiasm.

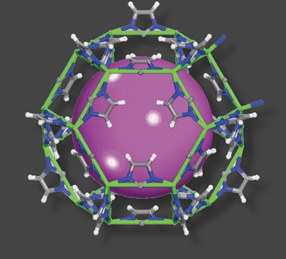

Working in Sandia’s Physical, Chemical and Nano Sciences Center, Nenoff creates and tests molecular sponges specially tailored to capture various chemicals. Her Sandia career began with optimizing porous clay-like zeolites to absorb radioactive ions from legacy nuclear waste. Her work has expanded far beyond that in both the sponge-like materials in her arsenal and their applications.

Notably, she worked on crystalline silicotitanates used to clean up contaminated seawater after the Fukushima Daiichi nuclear disaster in March 2011. “I think that being at Sandia enables my work to have a much broader effect than if I worked anywhere else,” says Nenoff.

Diverse and dynamic people

Spurred by her high school teacher, Nenoff studied chemistry at the University of Pennsylvania. Her original intention was to go to medical school afterward, but the combined experiences of doing research in a dynamic chemistry lab and spending a lot with a sick friend made her re-evaluate that decision.

Her undergraduate research was in the lab of Alan MacDiarmid on conducting polymers, the work for which he won a chemistry Nobel Prize in 2000. She enjoyed the cutting-edge multidisciplinary research, the diverse and dynamic group of people and the general creativity and excitement. It was such a heady and invigorating environment Nenoff has looked to recreate the nature of that team throughout her career.

After deciding not to go to medical school, she worked for a year and a half at Ciba-Geigy Chemicals just outside New York City. Nenoff liked the city, but realized that to be “the boss,” she would have to go back to school for a doctorate.

It was in graduate school at the University of California, Santa Barbara, that Nenoff learned zeolite synthesis and characterization, skills that formed the foundation of her career. Near the end of her doctoral work, Nenoff thought she was going to continue her fundamental research on zeolites in academia or industry, but Sandia came knocking.

Drawn to innovative research on nuclear waste cleanup — and the good local skiing — Nenoff joined Sandia in 1993.

“I’m a firm believer that to be successful at Sandia you need to have a core program, a mission-area driven program that gives you the continuity and the reason you’re here. But LDRD [Laboratory Directed Research and Development] lets me dive into different ideas and leverage off of these baseline programs I have and take them in different directions, build new customers, build new teams. It’s a really valuable program,” says Nenoff.

She was able to reconstruct at Sandia the multidisciplinary, creative environment of her undergraduate lab. The funding from LDRD projects lets her bring in vibrant, young postdocs such as Dorina Sava Gallis, Summer Ferreira and Koroush Sasan, many of whom have made the transition to staff.

There’s no “I” in team

In her core research and LDRD projects, Nenoff works closely with experts in many fields across the labs. Geoscientists and computer modeling people help design the molecular sponges. Folks in materials science determine the structure and characteristics of the resulting porous materials. Researchers take experimental results and analyze them in the context of real-world models.

And Nenoff, who was included in a book highlighting the careers of 100 women in ceramic and glass science and engineering by Lynnette Madsen of the National Science Foundation, has fruitful collaborations with researchers at other national labs and in academia. She works closely with Karena Chapman and Peter Chupas at the Advanced Photon Source at Argonne National Laboratory on the structural determination of the zeolites, metal organic frameworks and other nanoporous materials. She has a longrunning collaboration with University of California, Davis, physical chemist Alexandra Navrotsky, who provides technical expertise in calorimetry, a method for characterizing how well the sponges absorb their target chemicals.

“I have a great team of people I work with. We can be efficient and we can be creative. When you’re in an environment like that, lots of people like to join because it’s a fun environment. It’s easy to get stuff going and get going quickly. It ’s also important to recharge, so when I leave work, I leave work. For the most part I can clear my head and enjoy the rest of the day,” says Nenoff.

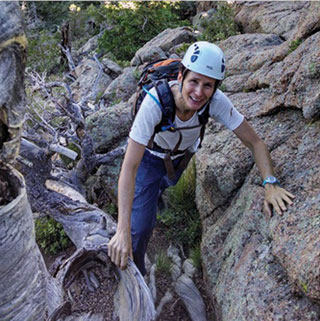

That ’s when Nenoff turns to travel and the outdoors, particularly skiing in Taos, road biking and rock climbing. She spent a summer scuba diving in Fiji and has biked through France several times. Her idea of a great vacation is one that takes her out of work so thoroughly, she forgets all of her passwords.

Separating oxygen from air

Tina Nenoff recently completed a Laboratory Directed Research and Development project in which she and colleagues designed and tuned porous materials, in this case metal organic frameworks, to selectively remove oxygen from air.

The work was important because the traditional way of doing that, for the most purified air, is cryogenic. Air is frozen to very cold temperatures, which separates oxygen from other components like nitrogen and argon. But it is energy-intensive. Other porous materials work, but are selective for nitrogen, and oxygen still has to be purified and carbon dioxide pulled out.

The Sandia method pulls out oxygen only. The project was basic research with a real-world application, specifically oxy-fuel combustion using oxygen for higher efficiency furnaces. Using oxygen versus air is more energy efficient. Sandia secured a few patents from the research and is talking to industry, particularly in glass melting, about licensing the materials.