B61-13 program begins

Responding to a critical challenge and urgent need, the B61-13 program used innovative program planning that resulted in projected delivery seven months earlier than expected, a more than 25% decrease in overall time to first production unit. The B61-13 team reprioritized qualification activities, planned tests with U.S. Air Force stakeholders and jointly completed requirements with Los Alamos National Laboratory and NNSA. Their creativity in system qualification put an aggressive set of plans in motion to meet stakeholder expectations. • 1000, 2000

Cross-enterprise team rethinks weapon design and delivery

A subteam of the Enhanced Mission Delivery Initiative Stockpile Modernization working group, with representatives from all NNSA laboratories, plants and sites, made a significant effort to understand what it would take to deliver a weapon system in less than five years — from DOD documentation through a letter of intent to the final rate production. This clean-sheet approach to weapon design and production will be applied to the Sea-Launched Cruise Missile-Nuclear program, and some aspects of the approach will be applied to the W93 program. • 0003, 1000, 2000, 5000, 6000, 7000, 8000

Mk21 Fuze quality engineering release comes ahead of schedule

An acceptable qualification engineering release for the Mk21 Fuze modernization program was 10 weeks ahead of schedule, which enabled an early first production unit at the Kansas City National Security Campus. To achieve the early release, team members from multiple divisions and from KCNSC collaborated to address technical, manufacturing and programmatic challenges. This achievement demonstrates the level of commitment and technical excellence the team displayed in delivering a critical component to the nation’s nuclear weapons stockpile. • 0003, 1000, 2000, 5000, 7000, 8000, 10000, KCNSC

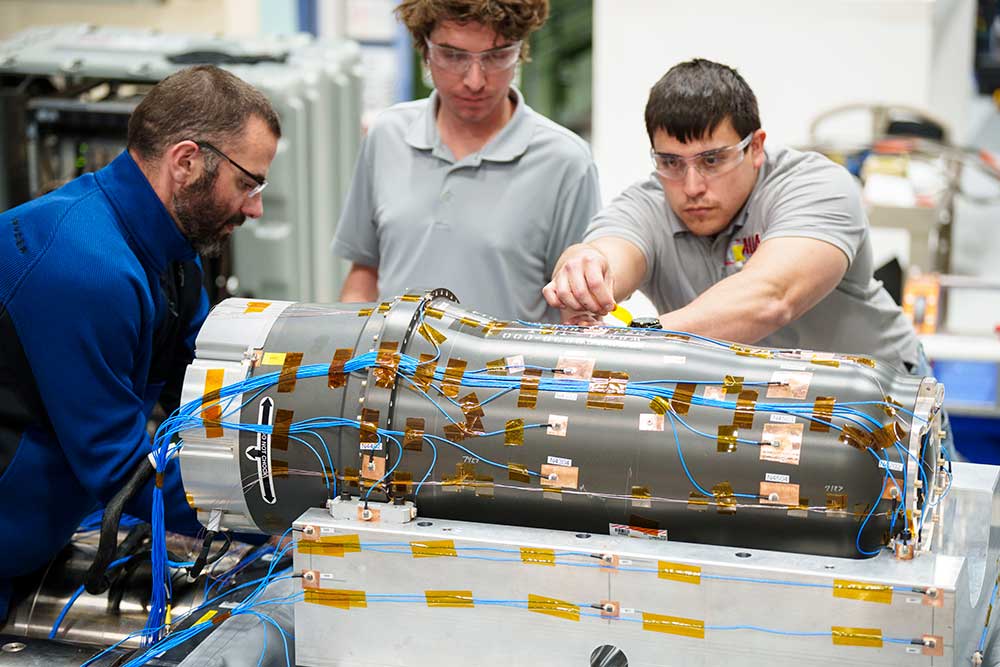

W80-4 warhead and missile integration

Sandia’s W80-4 Integration Test team, in partnership with Raytheon and Lawrence Livermore National Laboratory, successfully completed a series of combined missile and warhead ground tests incorporating version 2 joint-test-assembly-configured warhead hardware along with the latest Long Range Stand-off missile hardware. The ground tests met several objectives to provide confidence in the integrated functional performance of the warhead and missile in preparation for flight testing. • 1000, 2000, 8000

W76-1/2 program completes critical qualification testing

The W76-1/-2/Mk4B program overcame a critical qualification step by completing the Hazards of Electromagnetic Radiation to Ordnance testing. The testing ensures that the system will remain safe and maintain performance when exposed to electromagnetic radiation sources during its lifetime. The testing validated the performance of the joint flight assembly, the Mk4B system and the W76-1/-2 ALT 939 Integrated Surety Architecture and represents an important milestone for all three programs toward first production units. • 1000, 2000, 6000, 8000

Rapid setup of SLCM-N teams and framework

The rapid development of the Sea-Launched Cruise Missile-Nuclear program is unprecedented, and the nation is standing up the nuclear deterrence program in record time. As a member of the cross-site team, Sandia is managing Phase 6.2 feasibility and down-selection, including a study on alternative warheads in fiscal year 2025. Sandia stepped in to support NNSA and DOD customers and led enterprise-wide teams to develop a down-selection framework to support decision-makers. • 0003, 2000, 8000

Heavy ion screening approach sets new standard

The Electronic Parts program collaborated with teams across the Labs to develop a heavy-ion screening approach, enhancing the understanding of fast neutron effects on commercial electronic parts. The team successfully piloted the method so it can be used with front-end assurance of commercial parts. Their work sets a new testing standard by ensuring the reliability and performance of electronic components earlier in nuclear deterrence program development and will allow for faster insertion of parts into systems. • 1000, 5000, 7000, 8000

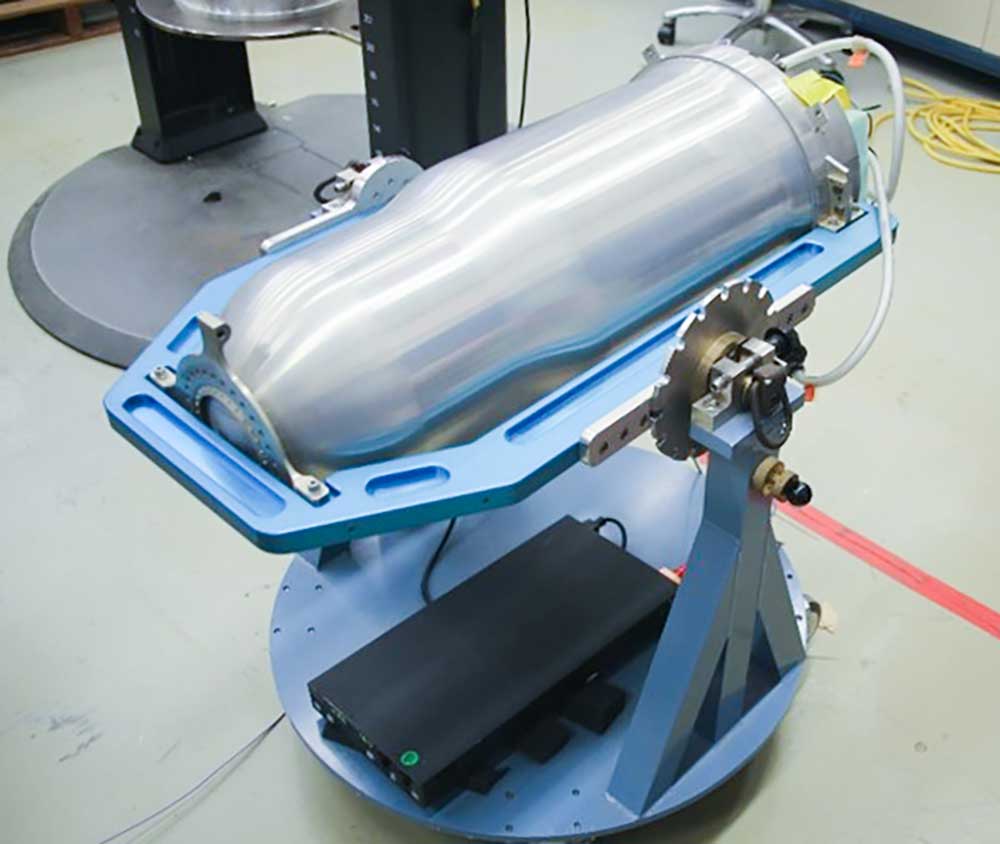

Improved infrastructure and technology for future reentry vehicles

Sandia’s Air Force Nuclear Delivery System team is helping reinvigorate the nation’s infrastructure and technology base for future reentry vehicle development, saving government resources and providing more opportunities for collaboration. The team achieved a successful systems requirements review for the Minerva flight vehicle less than a year after program kickoff and assembled an integrated development plan to meet aggressive schedule requirements set by the U.S. Air Force. Sandia incorporated past successes in conventional and nuclear weapons missions to achieve rapid progress in technology development. • 0003, 1000, 5000, 7000, 10000

New centrifuge completed at WETL

A new centrifuge was completed at the Weapons Evaluation Test Laboratory in Amarillo, Texas, that will enable Sandia to perform more non-nuclear testing faster. WETL is the only DOE laboratory that supports full system-level testing, is responsible for nonnuclear testing and leads the evaluation of every system, subsystem and component in the U.S. nuclear arsenal. The centrifuge was needed immediately to address the ongoing expansion of WETL’s workload and represents a strong and busy future for the facility. • 2000, 4000, 7000

ISA program reaches key milestones

The Integrated Surety Architecture program retrofitted the first convoy of Safeguard Transporters to the proper configuration and completed the first shipment of the W88-0/Mk5 ALT 940 system to the U.S. Navy. The ALT 940 system attained initial operational capability, while the retrofit enabled the first fleet use of such a trailer in support of national security. Additionally, the Sandia Production Agency delivered more than 600 diamond-stamped components and completed all ISA production activities at Sandia. • 2000, 6000, 7000

Space radiation testing

The W87-0 and W87-1 teams successfully completed space radiation testing to evaluate potential impacts on telemetry performance during Sentinel test flights. The teams addressed new environmental requirements specific to Sentinel that were not present for Minuteman III. Within three months, they engaged in comprehensive planning, test execution and analysis to deliver a thorough risk assessment and the corresponding documentation. This analysis was essential in supporting the W87-0 and W87-1 Sentinel integration missions. • 2000, 8000

AI enables automated material analysis

Sandia has harnessed the power of image analysis via machine learning to automate inspection and validation of incoming components and materials in a scanning electron microscope. Teams developed custom software to quantify the metal content in metal-ceramic composites. The software automatically operates the scanning electron microscope stage; acquires images from targeted areas; uses a convolutional neural network to quantify the composition; and prepares a draft report. Using artificial intelligence in this way can reduce labor, eliminate human error and increase consistency in the execution of routine analytical work. • 7000

W87-1 program meets milestones and pursues efficiencies

Sandia completed all component conceptual design reviews and conceptual design gates for the W87-1 Modification program. As requirements continued to mature, the Labs completed multiple successful builds and tests of development configurations. Sandia also improved program execution, including a focused effort on better schedule logic and an evolution of a risk-informed approach for required environments and integration testing with the U.S. Air Force. This effort enabled approval of a joint flight test with the Mk21A program ahead of projected Sentinel missile schedules. • 0003, 1000, 2000, 3000, 5000, 7000, 8000, 10000

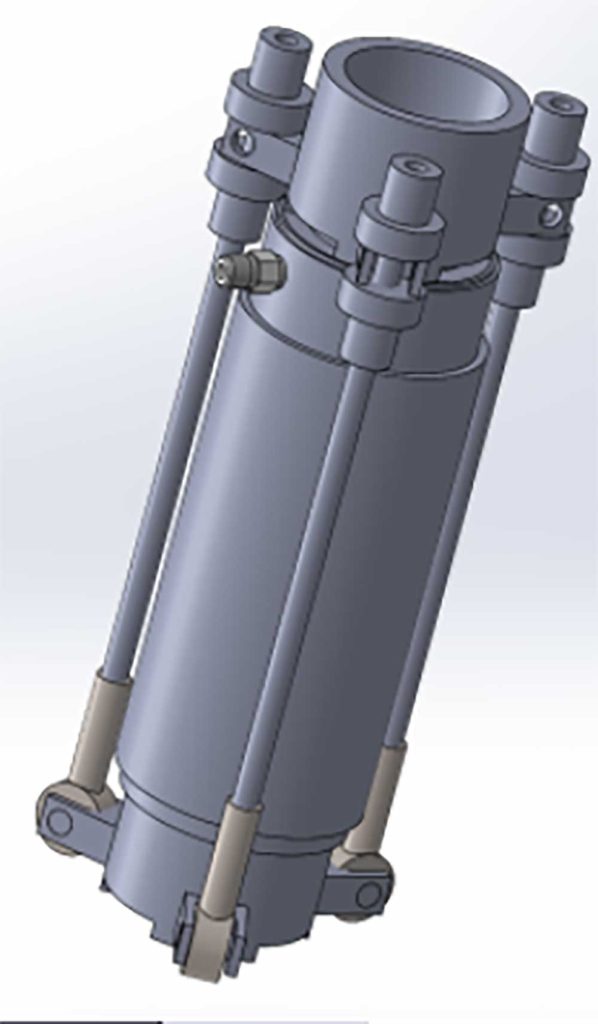

Actuator redesigned and delivered to avoid production impacts

Sandia redesigned the explosive actuator component to meet specific requirements for the W80-4, delivering in only 15 months the first W80-4 actuator War Reserve lot and avoiding production impacts at the Kansas City National Security Complex and Savannah River Site. The project succeeded through strong partnerships, solid technical work and focus on the mission. • 2000, 7000, 8000, 10000, KCNSC, SRS, NNSA

Technical Expert Networks expand support across Labs

Three new Technical Expert Networks focused on environments, nuclear safety and radiation effects were added to three existing networks on additive manufacturing, energetics and materials. This doubles the number of frameworks available to help resolve technical roadblocks faster and further accelerate engineering work to meet urgent delivery commitments. The networks include experts across the Labs who provide program-relevant solutions, advise on broader engineering applications and support independent peer reviews. • 0003, 1000, 2000, 5000, 6000, 7000, 8000

Security assessment complete for MoPD

The security assessment process for the Modernized Protection Device is complete, representing successful efforts by more than 20 Sandians over a seven-year project lifecycle. The MoPD is a government-owned package of hardware and software intellectual property that implements GPS cryptography and information assurance. MoPD 1.1.0 is being used by multiple military GPS user equipment developers after the GPS Certifications Branch chief issued a memorandum that MoPD successfully completed the Run for Records milestone. • 5000, 6000, 7000

W93 system design matures

The W93 development team worked closely with production agencies, Los Alamos National Laboratory, Lockheed Martin Corp., the U.S. Navy and NNSA on a mature system design for the submarine-launched weapon. Planning, execution and documentation of requirements reviews, peer reviews, technology selections and joint trade studies involved integration across many stakeholders and have prepared the program to enter Phase 2A, Design Definition and Cost Study. • 0003, 1000, 2000, 3000, 5000, 7000, 8000, 10000

First impulse test on W87-1 successful amid construction

During an intensive construction project that doubled the size of the Light Initiated High Explosive facility, the Labs successfully completed a full schedule of explosive tests, including satisfying objectives and obtaining required data for the first impulse qualification test for the W87-1 system. The test required coordination with multiple stakeholders, including Lawrence Livermore National Laboratory, the U.S. Air Force and Lockheed Martin Corp. A strong partnership between multiple Labs departments and construction contractors enabled explosive testing to continue during the facility expansion project. • 1000, 2000, 4000, 7000

Disablement Management System Mod production complete

Disablement Management System Mod, a surety enhancement program, finished production activities and is nearing completion of field installation. The program began in October 2020 with the first full shipment, followed by installation in 2023 and completion of production in fall 2024. Through Labswide collaboration in this logistically complex project, design and production of all six main components were completed, resulting in delivery of 838 diamond-stamped components. • 0003, 2000, 6000, 7000

High-tempo telemetry tests advance weapons programs

The telemetry mission area achieved significant milestones across 10 development programs and eight stockpile programs, providing valuable data collection and analysis for nuclear weapon systems. The teams supported nine flight tests, completed three formal design reviews, delivered 22 telemetry assemblies to system level tests and collaborated with partners to ensure seamless requalification of products at a new facility. • 8000

W80-1 team develops test simulator

The Air-Launched Cruise Missile used for the W80-1 warhead employs a conventional test instrumentation kit door for W80-1 flight tests, which are crucial for state-of-health assessments. Due to obsolescence, the current conventional test instrumentation kit is being replaced with a new one that requires qualification and certification. Sandia’s W80-1 team pivoted to address this unanticipated need and partnered with surveillance, telemetry, test assembly, environmental test facility and other teams to deliver a joint test assembly 8 simulator that will ensure uninterrupted flight testing. • 8000

Team completes W93 launch accelerometer initial build

Sandia completed the initial development build and level-four technology readiness testing for the W93 launch accelerometer in just 18 months from initial requirements to completed testing, while achieving unprecedented results in closure time consistency and minimizing electrical chatter. The design integrated the most effective and manufacturable aspects from current and historic models and was completed in partnership with the production agency, ensuring accelerometer performance and manufacturability. • 1000, 7000

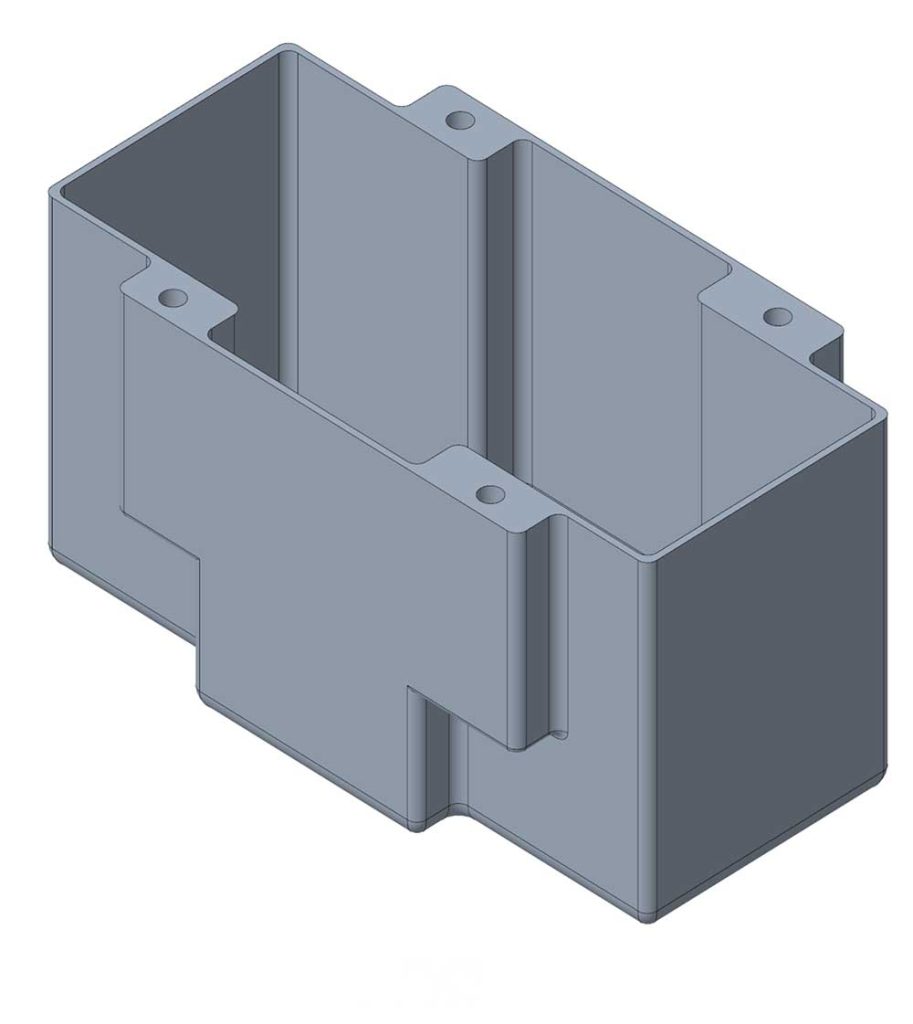

Pilot advances digital engineering through model-based design

The Labs demonstrated the feasibility of a model-based design future through a pilot that included the design of a complex mechanical part, manufacturing at a supplier, inspection at a supplier and stocking at Sandia — all using a common 3D model rather than 2D drawings. Teams documented lessons learned, best practices and challenges throughout the pilot to further inform and advance the digital transformation of the national security enterprise. • 0003, 2000, 7000, 9000

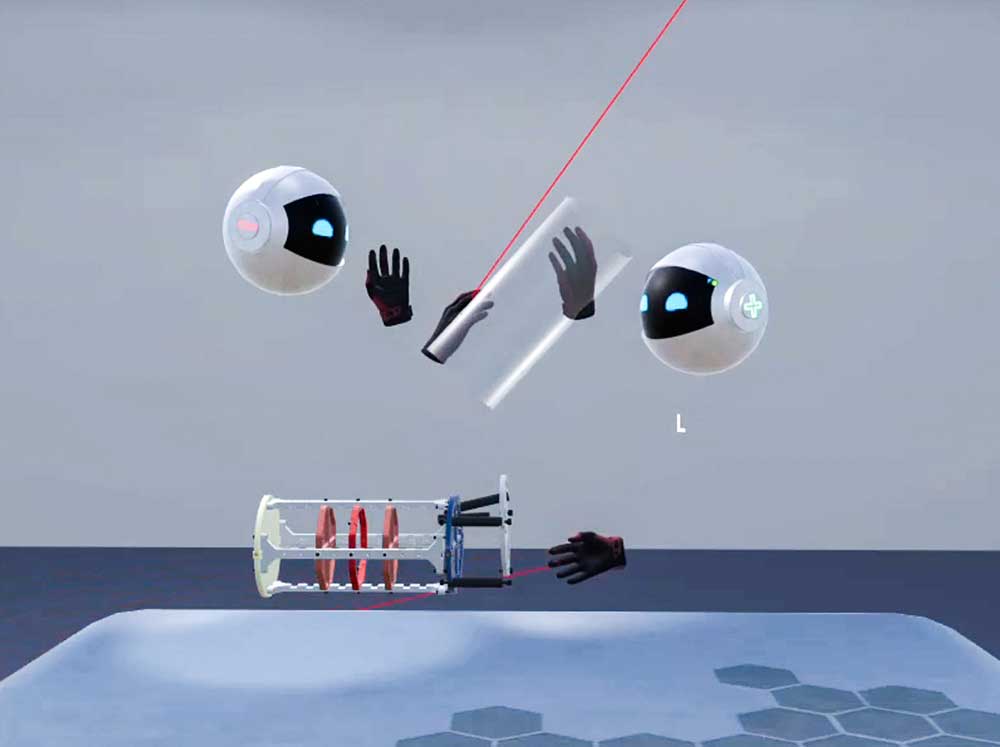

New approach to classified virtual interactions

Sandia’s extended reality team collaborated across four buildings in California, New Mexico and Texas to showcase four-way classified virtual interactions that enable accelerated collaborative development and delivery of critical components. The team also demonstrated systems depicting a virtual assembly process. The Extended Reality Engineering Visualization effort supports digital engineering transformation work across the entire weapon product lifecycle. • 0003, 2000, 6000, 8000, 9000

New rotational program for early career staff

The Advanced Mechanical Design group launched an early career program to allow participants to rotate through four six-month opportunities and engage in a variety of projects. The Mechanisms Rotation Experience Program improves the onboarding experience for staff, broadening their exposure and helping them develop a strong foundation in engineering skills for a variety of critical roles. This pilot program will be evaluated for potential implementation across Sandia. • 7000

W80-4 Systems qualification testing success

The W80-4 systems qualification testing team successfully completed qualification assurance test unit, thermal 3, and mechanical environments 3 testing using version 2 hardware. This version is expected to be very similar to the final production hardware. While data is under review and final system qualification testing will take place with mostly hardware from the production agency in fiscal year 2026, analysis thus far indicates the W80-4 system will meet requirements through a lifetime of mechanical shock and vibration environments. • 2000, 8000

Reusable thermal battery test case introduced

Sandia developed a reusable thermal battery case designed to gather more electrochemical and thermal performance data. The system features enhanced temperature mapping and multiple electrical feedthroughs, enabling precise monitoring of high-capacity, high-power batteries. The design also allows easy component replacement without altering geometry. With active compressive load monitoring and synchronized signal timing, the case enables rapid collection of critical data, driving future design improvements and ensuring superior performance in demanding environments. • 7000

Rapid development connectors impact multiple programs

A multidisciplinary team of Sandians established a new capability for the rapid development of custom electronic connectors. The capability delivered significant benefits across the W87-1, W93 and other weapon programs, saving nearly three years of work and $250,000 in unnecessary procurements. In collaboration with NNSA, the team developed advanced part designs, tooling and processes to enhance production efficiency and quality for the nuclear deterrence mission. • 1000, 7000

MissionTech brings future talent to Sandia

The Nuclear Deterrence Mission Technologies Intern Institute, or MissionTech, welcomed over 70 summer interns to New Mexico and California in its inaugural year, strategically developing and securing a talent pipeline. Supported by ND leadership as a sustainable program, MissionTech creates a mutually beneficial environment for students and staff. This commitment to growth was reflected in the conversion of 64% of summer interns to year-round positions. • 0003, 2000, 7000

Transportation weapon response refreshed

Sandia released the weapon response documentation package for the NNSA Office of Secure Transportation Documented Safety Analysis, supporting safe transportation operations in 2025. In 2020, the NNSA launched the Secure Guardian Transporter Over-The-Road Weapon Response Refresh effort to enhance weapon transportation safety, which requires collaboration between teams from the OST; Sandia’s Transportation System Analysis Team, Engineering Sciences and Stockpile Systems; and weapon response teams from across the nuclear security enterprise. • 1000, 2000, 6000, 8000