Emergency Management puts itself to the test

Sandia held a comprehensive exercise in June to evaluate its ability to respond to a wide range of emergencies. Such exercises play a pivotal role in ensuring protection of the national security mission. CyberShock 24 featured simulated seismic activity and cyberattacks that created cascading events for 450 participants and required six months of planning by 78 internal and external agencies and organizations. The exercise demonstrated that Sandia can respond to a severe event that affects critical infrastructure while maintaining focus on continuous improvement. • 4000

Power Sources Capability project achieves preliminary design

The Power Sources Capability project delivered its preliminary design to NNSA and initiated the final design phase, with anticipated completion in 2025. Site preparation activities, including site clearing, demolition and utility installation, followed by full construction, are expected to begin in the summer. The Power Sources Capability is the Labs’ first line-item construction project to be contructed in over 15 years. • 4000

Proactive safety campaigns reduce injuries

The Labs significantly reduced injuries and illnesses and days away from work through proactive awareness campaigns in key safety areas. Additionally, Sandia increased leadership and staff engagement in safety discussions, refined case management, deployed safety culture principles, enhanced ergonomic assessments and expanded learning opportunities. Sandia continues to integrate recent innovations in worker safety and health. • 4000

Enhancing safety, energy efficiency in laboratories

Team members from Facilities and Environment, Safety and Health launched the Federal Energy Management Program Smart Labs initiative, aimed at creating safer and more energy efficient laboratories through high-performance methods. The Smart Labs team completed a Laboratory Ventilation Risk Assessment pilot in the Integrated Materials Research Lab, which led to significant reduction in air flow, $15,000 in electricity savings and enhanced lab safety. • 4000

Rapid response to PFAS unavailability

The cross-site at-risk materials team rapidly responded to the discontinuation of many PFAS-containing materials by the 3M company, ensuring there would be no impact on nonnuclear component production schedules, despite PFAS use in several components and all systems. The team collaborated across business units and sites and used modern engineering tools and practices to determine the full extent of the impact to begin mitigation and deal with the risk posed by PFAS-containing materials from other manufacturers in the stockpile. • 1000, 7000, 8000, 10000, KCNSC, LANL, LLNL, PX, SRNL, Y12

All-in on safety culture

Sandia has pivoted from a reactive to an innovative and proactive approach that is driving safety culture improvements. This transformation includes the introduction of the Safety Sync, which provides dedicated time for all teams to engage in meaningful safety discussions, ensuring that safety remains a top priority. Complementing this initiative, the Safety Culture Academy offers essential training and resources that align with safety culture principles, to enhance the Labs safety practices and foster a culture of safety. • 4000

CREST nears critical decision approval

The Combined Radiation Environments Survivability Testing project team, composed of staff from across multiple centers, divisions and external resources, worked for three years to deliver critical decision documents to NNSA for independent project review. The team produced over 70 deliverables — more than 14,000 pages — detailing the complex conceptual design, cost and schedule for the recapitalization project. The team expects to receive critical-decision approval in 2025. CREST will replace the Annular Core Research Reactor facility and other key nuclear facilities, making it Sandia’s second capital acquisition effort in a decade. • 1000, 4000, 10000

New California facility expands ND capabilities

Multi-Program facility at Sandia California will enhance classified subtractive manufacturing capabilities. The manufacturing services program and operations team outfitted new machining equipment and construction in an environmentally controlled laboratory inside the high-bay facility. The complex will serve as the inspection facility for making precision measurements to ensure fabricated parts meet dimensional specifications. The manufacturing services program and operations team will continue to enable nuclear deterrence and other mission work. • 8000

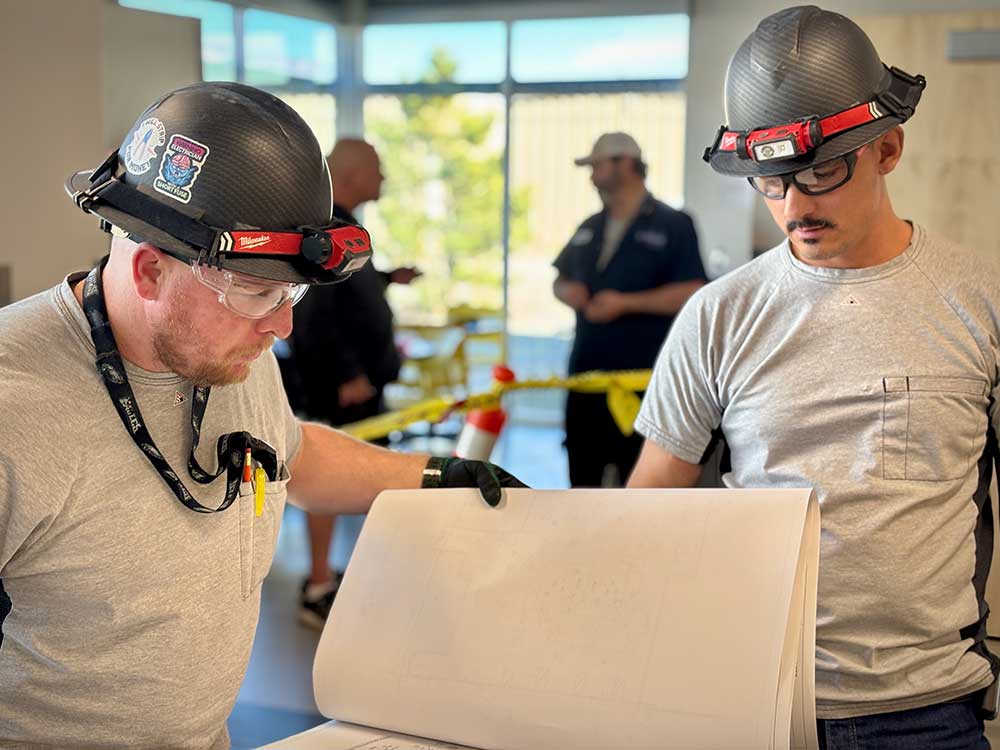

In-house capabilities support mission work

In the last two years, the Infrastructure Operations division has increased delivery of timely services to support mission work and streamlined its operations through an initiative called Division Agility Transformation. The transformation involved forming In-House Construction and In-House Design teams and hiring architects, planners and craftspeople to fill new positions. The In-House Construction team mobilized quickly and completed 76 projects in 2024. The In-House Design team also completed 198 projects and reduced the office modification backlog by 80%. • 4000

Environmental impact statement developed through collaboration

Sandia engaged staff in developing a sitewide environmental impact statement, which will support sustainability and compliance with the National Environmental Policy Act through 2041. The Sandia support team and experts analyzed current and future infrastructure, operations and capabilities that enable Sandia to perform mission activities while protecting the environment. The Labs collaborated with external entities, including Kirtland Air Force Base, the U.S. Forest Service and the Pueblo of Isleta. A preliminary draft of the statement was distributed to key stakeholders for review. • 4000

Lidar scanning technology saves time and money

The Facilities Computer-Aided Drafting and Design and Building Information Modeling team streamlined their operations with lidar. This system uses laser light to create precise 3D models and is packaged in a backpack-like device. The team uses lidar to capture as-built conditions, monitor construction phases, enhance design and planning, do field verification and develop virtual twins of the Sandia campus, buildings and systems. Sandia is the only national lab that can perform this 3D scanning in-house. The team has performed six scanning jobs, consisting of 123 scans and 265 hours of scanning and postprocessing. • 4000