B61-12 ACCD release

The Aircraft Compatibility team, with the assistance of the B61-12 Systems teams, successfully released the first B61-12 Aircraft Compatibility Control Drawing (ACCD) for the F-15E aircraft. The ACCD is critical to the B61-12 Major Assembly Release, which certifies the extent to which this weapon design meets its Military Characteristics, Stockpile-to-Target Sequence and applicable interface requirements. The ACCD release, which culminated over six years of testing and analysis, granted F-15E and B61-12 compatibility and codified that the electrical and mechanical interfaces meet requirements. (2000)

B61-12 Life Extension Program achieves stockpile acceptance

A Final Design Review and Acceptance Group panel met in September to determine compliance of the B61-12 final design with requirements. The panel concluded that NNSA, Sandia and Los Alamos National Laboratory have successfully demonstrated that the B61-12 meets all safety and surety requirements and is fully qualified for all evaluated environments. The panel recommended acceptance of the B61-12 as a Limited Stockpile Item, with acceptance as a Standard Stockpile Item upon successful completion of the Qualification Design Review of the Base Metal Electrode capacitor respin qualification testing. (2000)

W76-2 final production unit

The W76-2 program was executed on a highly accelerated timeline to implement the Nuclear Posture Review’s direction to develop a low-yield submarine-launched ballistic missile. The work of the Stockpile Systems Product Realization team jointly with teams across the Nuclear Security Enterprise laid the foundation for successful execution. The program started with a 6.2/6.2A study in January 2018 and completed first production unit on February 2019. The W76-2 was accepted into the U.S. nuclear stockpile by the DoD and the W76-2 final production unit was completed in June 2020. (2000)

ND programmatic equipment investment tool

The Nuclear Deterrence (ND) Program Management Office led a multidivisional (divisions 1000, 2000, 5000, 6000, 8000 and 9000) effort to create a tool to manage programmatic capital equipment inventory and investment needs to sustain ND capabilities. This tool improves the efficiency, consistency and traceability of equipment needs to capabilities, and provides a single integrated list to rapidly prioritize investments across the ND portfolio to enable rapid decision making in response to funding opportunities and operational needs, and to improve annual NNSA Future Years Nuclear Security Program budget planning. (2000)

Successful W88 ALT 370 respin qualification testing

Over the past 18 months, the W88 ALT 370 program rapidly responded to capacitor respin, and successfully planned and executed a series of qualification tests and analyses necessary to prove in new respin designs and in support of a System Qualification Evaluation Release. This included testing under an array of environments, such as electrical, radiation and missile integration, at the major component, subsystem and system levels. This monumental effort was accomplished with collaboration and support across the Labs. (1000, 2000, 5000, 9000, 10000)

B61-12 conducts F-35A testing

The B61-12 Life Extension Program (LEP) completed umbilical certification pull testing and aircraft integration testing for the F-35A fighter jet. These tests ensure that the umbilical cable will accurately separate from the weapon, and that the weapon integrates with platform software and hardware. In addition, an F-35A aircraft successfully delivered one B61-12 Guided Test Vehicle flight test unit at the Tonopah Test Range on Aug. 25, 2020. This flight test was the first of four Enhanced Fidelity Instrumentation flight test units planned for F-35A compatibility testing. (2000)

Creative telemetry training for staff

ND Weapon Engineering Professional Development transformed mandatory training during the pandemic by creatively using online training methods, allowing members of the workforce to comply with COVID-19 guidance and remain current with all ND training requirements. The new approach offers classes via live e-learning platforms and through previously recorded sessions. Examples include several comprehensive, multiday telemetry and telemetry software analysis tool training classes. Over 95% of existing training was made available, enabling over 3,300 students to remain up to date while effectively eliminating possible COVID-19 exposure. (2000, 5000, 8000)

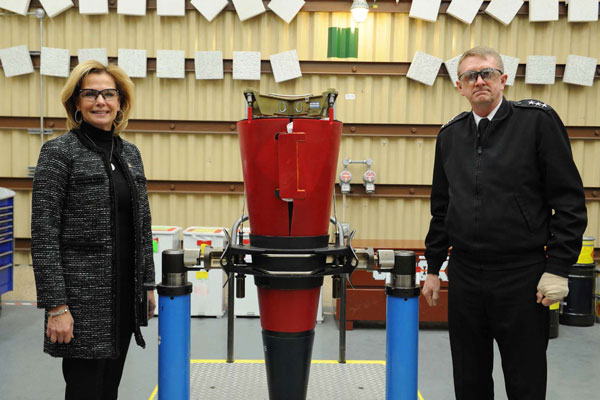

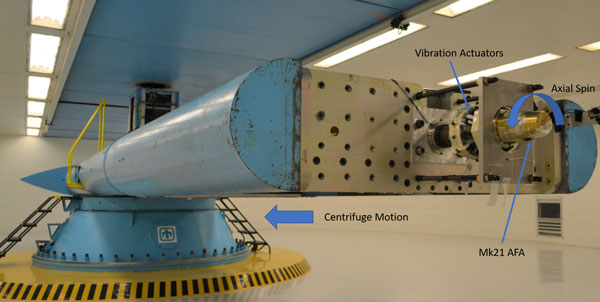

Mk21/AFA superfuge combined mechanical environments

The Mk21 Arming Fuzing Assembly Qualification team, along with the Mechanical Environments team, successfully conducted the first combined mechanical reentry environments test with fully powered, operational test hardware. The Tech Area III superfuge test consisted of three simultaneously applied normal mechanical reentry environments, including acceleration, axial spin and random vibration. This new capability further closes the gap between flight and ground testing in the Nuclear Deterrence community at Sandia and the DOE complex. (1000, 2000)

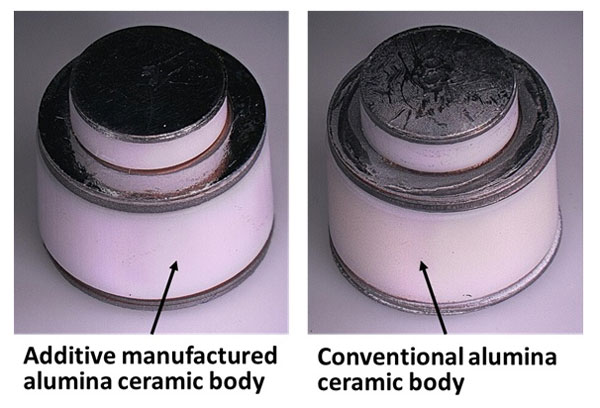

Demonstration of additively manufactured (AM) sprytrons

A fully functional sprytron was demonstrated using an AM alumina ceramic body printed on a ceramic AM capability newly commissioned in house at Sandia. The supplier of the AM tool is certified to formulate Sandia’s proprietary base material. The AM ceramic brazed hermetically, and life testing indicated equivalent performance to conventional sprytrons. This demonstrates the potential to shorten the sprytron ceramic body procurement cycle by up to 75% and enables incorporation of new insulator design features and creation of parallel design variants during development cycles. (2000)

Cycle 25 annual assessment

Sandia delivered the Laboratories Director’s annual nuclear weapons stockpile assessment letter, which summarizes the safety and reliability of the nation’s nuclear weapons stockpile. Sandia conducted a two-week Laboratories Director nuclear weapons program review and organized the Labs’ participation in the U.S. Strategic Command’s Strategic Advisory Group Stockpile Assessment team review. Each review adhered to COVID-19 safety protocols. The unprecedented amount of logistical planning and coordination for these reviews was extremely successful. (1000, 2000, 3000, 4000, 8000, 9000)

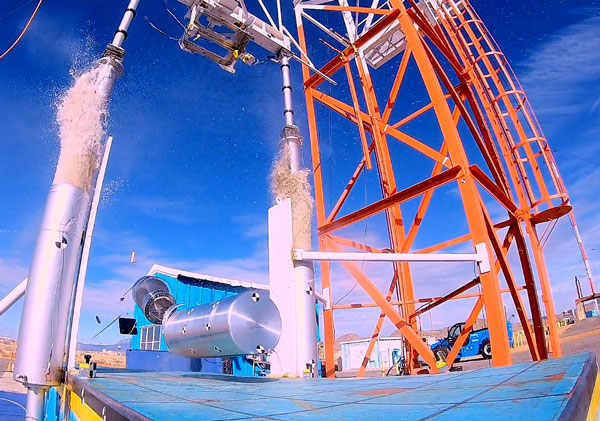

Stockpile responsiveness Davis Gun testing

Sandia’s Stockpile Responsive Program team successfully completed a series of tests in July and August 2020 using Sandia’s unique 16-inch Mobile Davis Gun. With an internal barrel diameter equal to the largest of the famed U.S. WWII battleships, the 16-inch Davis Gun can shoot payloads up to 2,000 pounds at high speeds. The team used the Davis Gun tests to provide valuable experimental data for comparison to computer simulations that model impact at high speeds. (1000, 2000, 5000, 8000)

ALT 370/940 production readiness

Production readiness for the W88 ALT 370 and W88 ALT 940 programs achieved a substantial milestone with the completion of Production Capability Units (PCU). The W88 ALT 370 program completed the second of two production capability units exercising the entire suite of assembly, disassembly and satellite facility operations. The W88 ALT 940 program demonstrated readiness by performing its first PCU. (2000, 9000, LANL, Pantex, Lockheed Martin)

W80-4 abnormal drop testing

Six drop tests executed from January through March 2020 comprised the successful completion of the Abnormal Shock Breach Phase 1 test series, culminating in the GTU1A drop from 285 feet. The tests were conducted at Sandia’s Tech Area III Drop Tower Complex in Albuquerque, in partnership with Lawrence Livermore National Laboratory. This test series will provide critical data for qualification teams to further understand W80-4 system response in abnormal mechanical environments. (600, 1000, 2000, 4000, 8000, 9000)

War Reserve parts delivered

Despite the COVID-19 pandemic, Sandia’s Production Agency delivered more than 38,300 war reserve parts in eight technology areas — power sources; explosives; neutron generators; Application Specific Integrated Circuits; Heterojunction Bipolar Transistors; Switch Tubes; ISA; and timers/detonators — affecting 71 major components. Sandia manufactured all NG, ASIC, HBT, and ISA parts on-site, more than 24,800 parts for 38 major components. (2000, 5000, 9000)

B-52H/W80-1 comprehensive test completed after years of delays

The Aircraft Compatibility team, with the assistance of the W80-1 Systems team, successfully completed comprehensive ground and flight testing on the B-52H aircraft. This test had been delayed for several years and required coordination with NNSA leadership, the commander of U.S. Air Force Global Strike Command, and the Air Force Nuclear Weapons Center. Joint USAF and Sandia testing was successfully completed across multiple aircraft at Minot and Barksdale Air Force Bases to assess continued aircraft and weapon interface compatibility despite the constraints associated with COVID-19. (2000, 8000)

Neutron generator foundation bus interface

Ferroelectric and electronic neutron generators were the first components to successfully integrate a timed input/output module to help realize distributed-bus-based architecture for future systems. This endeavor encompassed functional demonstration and environmental testing of packaged form factors in mechanical shock and thermal extremes. This standardized interface is the first step in enabling backward and forward compatibility to realize the vision of system agility through block upgradability. Next steps include the challenge of operating in other environments. (2000, 5000, 8000)

Sandia ISA production

Center 2500 has delivered significant ISA Production milestones, utilizing rapid development and production cycles. These include achieving Multi-application Transportation Attachment Device development build and process prove-in for the ALT 940 amid pandemic challenges, completing production, acceptance and deliveries for the ALT 372, and completing production and acceptance for the P19 program. Executing this work involved close coordination and partnership with teams across Sandia, Los Alamos National Laboratory and the Kansas City National Security Campus. Achieving these milestones demonstrates Sandia’s ability to deliver rapid production to meet urgent program and national security needs. (2000)

Advances in modeling dense plasmas

Scientists in the Neutron Generator Enterprise have developed a powerful new capability to model the dense, low-temperature plasmas used in these devices. By enabling 1,000-10,000 times faster simulation of the plasmas, this capability provides new insights into the normal and abnormal behavior of ion sources and allows for rapid exploration of design ideas and trade-offs with increased confidence. This capability is a critical element of a complete numerical model for these components, thus enabling a “digital twin” development. (2000)

Nuclear Deterrence Strategy v3.0

The ND and Weapons Science & Technology programs initiated a years-long integrated effort to drive technology, capabilities and processes to a more responsive/agile state for an uncertain future. The ND Strategy v3.0 provides a strategic framework to position Sandia to assure U.S. nuclear deterrence in a rapidly changing global environment. It provides a strategic vector and shapes priorities regarding sustainment of our capability-based science and engineering foundation. Strategic execution, via exemplars spanning the product lifecycle and Sandia’s programs, will drive to near-term impact and long-term transformation. (1000, 2000, 5000, 6000, 8000, 9000)

Completion of ALT 372

Division 2000 provided technical oversight for the U.S. Air Force to successfully deliver ALT 372. The on-site technical observers resolved Unsatisfactory Reports in real time, enabling mission success. Division 2000 provided Disablement Management System (DMS) 1st Generation Training to 63 personnel to three OCONUS Munitions Support Squadrons and published key UD1702-2 DMS Technical Procedure updates. Sandia’s unwavering support allowed the Air Force to execute this DMS Surety Program during the unprecedented COVID-19 pandemic. (2000)

W80-4 WHC DB1 design and build

After a major system design change on the W80-4, the Warhead Case team, including the Lightweight Structures Lab, worked closely with systems, the Mechanical Computer Aided Design team and the Kansas City National Security Campus to successfully redesign and build new hardware in less than a year. This major achievement for the team is even more impressive with the ongoing constraints of the pandemic. (8000)

Mk21 Fuze major milestones achieved

The Mk21 Replacement Fuze program achieved several major milestones in FY20, including a successful developmental flight test, a programmatic re-baselining up to First Production Unit and completion of numerous developmental test series. The program received a favorable pass with no conditions at the Final Design Review. The program is now pivoting to Process Prove-In and is on track to provide the U.S. Air Force with a modern arming and fuzing capability for the strategic land-based deterrent. (1000, 2000, 8000)

Sharing supplier evaluations saves $1 million

Saving a projected total $1 million in FY20 and FY21, Sandia and Kansas City National Security Campus co-led an effort that allows secure sharing of supplier assessments across the Nuclear Security Enterprise. Los Alamos National Laboratory subsequently used Sandia’s audit of an electronics parts supplier in its quality management system review of the same supplier, saving employee time and associated costs. This marked the first time LANL used a Sandia audit report to complete such a review. (9000)

Sandia processes record number of weapons components

Sandia processed a record number of components for weapons, neutron generators, power sources, energetics and microelectronics during FY20. The Labs’ quality processing of 458 product submittals exceeded its most recent eight-year average by 195%. Sandia’s weapons quality assurance team accepted 113,919 units into the stockpile, up by more than 140% over FY19. Innovating to fulfill its critical mission during the pandemic, Sandia also completed its first-ever virtual visual quality inspections. (9000)

W88 ALT370 Telemetry First Production Unit

The W88 ALT370 Telemetry Assembly supporting the Joint Test Assembly 8 achieved the First Production Unit milestone in June 2020. The Kansas City National Security Campus produced the unit, which was successfully incorporated into the next level assembly and delivered to Pantex. (2000, 8000)

Sandia HPC among world’s fastest

Sandia’s Attaway High Performance Computer placed 94th on the November TOP500 list of the world’s fastest supercomputers, with a Linpack benchmark of 2.7 PetaFLOPS. A more advanced sister system, Manzano, acquired at the end of FY20, will be placed into operation in early FY21, with expected Linpack of 4.3 PetaFLOPS. Between the two systems, Sandia has added more than a billion processor-hours per year to serve the computational needs of its national security missions. The system was named to honor the late Sandia engineer Steve Attaway. (9000)

Qualification testing proves flight worthiness of W80-4 test unit

The W80-4 team completed extensive testing to demonstrate flight worthiness of the Environmental Test Unit 1, an instrumented test asset that provides captive carriage environmental data for warhead qualification. A pre-ETU1 test unit withstood vibration and shock testing at multiple temperatures to prove survivability and proper function for a full ETU1 lifetime. The testing also demonstrated the robustness of the warhead design — including new bolted joints — in transportation and captive carry flight environments, and supported on-time delivery of ETU1s to the Air Force. (8000)

B61-12 Telemetry First Production Unit

Telemetry supporting the B61-12 Joint Test Assembly achieved the First Production Unit milestone in January 2020. The unit, produced by the Kansas City National Security Campus, was successfully incorporated into the next level assembly and delivered to the Pantex Plant in Texas. (2000, 8000)

SPEAR expands California test, assembly capacity

The Sandia Programs Engineering and Assembly Research facility opened in summer 2020, providing state-of-the-art assembly and electrical testing capabilities for current and future modernization programs. The SPEAR team promptly completed several milestones, including CASE 1, one of the most comprehensive builds of the W80-4 to date. The team also delivered two W80-4 Warhead Electrical System decks for environmental testing and qualification, updated numerous W80-4 Fit Check Unit-3s with design modifications and developed complete 3D-printed parts for W80-4 cutaway construction. (8000)