A joint Department of Energy/Spanish/Korean project was conceived, designed, and managed by Sandia to quantify the shocks and vibrations spent nuclear fuel experiences during transport. A storage/transportation cask containing surrogate nuclear fuel was transported by truck in Spain, by ship to Baltimore, and by rail to Colorado for specialized tests. Data – 6 terabytes – were continuously collected over 9,600 miles. Strains measured on the surrogate fuel tubes will be compared to the strength of irradiated zirconium to assess the fuel’s ability to withstand extended storage and transportation. (8800, 1000)

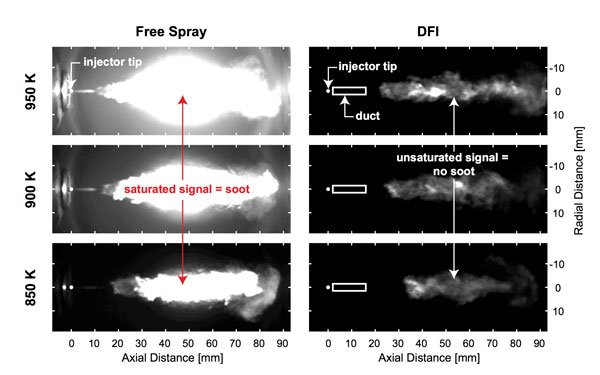

Sandia engine researchers are exploring ducted fuel injection (DFI), a new concept where fuel is injected through a small, cylindrical duct aligned with the fuel axis. Orders-of-magnitude soot reduction was demonstrated, which shows great promise for typical diesel engines. DFI may also increase combustion efficiency by decreasing unburned hydrocarbons and carbon monoxide emissions. DFI research is funded by DOE’s Office of Vehicle Technologies and is supported by work-in-kind from Caterpillar and Ford via a cooperative research and development agreement. (8300)

Sandia’s electric-grid researchers received two R&D 100 awards in 2017. One is for the Microgrid Design Toolkit, a publicly available software product that uses powerful search algorithms to help microgrid designers explore technology and performance trades in the preliminary design phase. The second is for a control system that damps oscillations in transmission lines using new smartgrid technology, enabling greater grid stability, higher power flows, and lower costs. The control system was proven effective during demonstrations on the Western US power grid. (8800, 1000, 5000, 6000)

Every five years, DOE must submit a compliance recertification application (CRA) to the Environmental Protection Agency for the Waste Isolation Pilot Plant (WIPP). In July 2017, EPA approved the WIPP application submitted in March 2014. Sandia contributions were central to that recertification application. Sandia’s estimates of WIPP’s cumulative releases 10,000 years into the future are informed by fundamental studies in geochemistry, geohydrology, and geomechanics. The application was some 2,100 pages long, and Sandians authored or coauthored 1,700 of those pages.

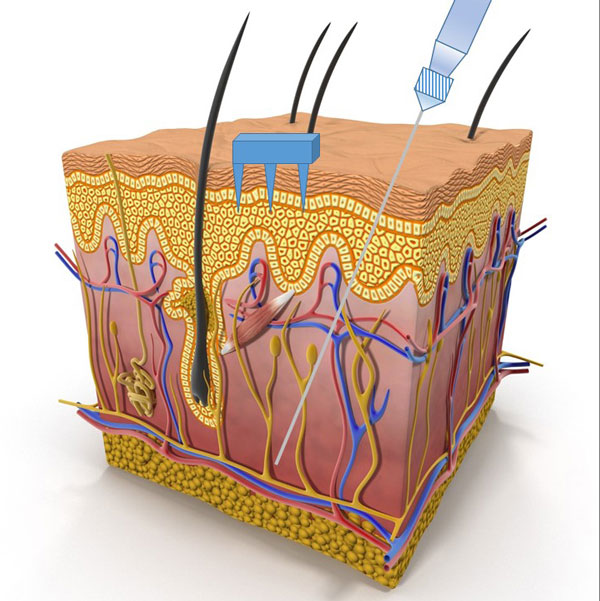

Sandia-designed microneedle sensors can extract interstitial fluid, the clear fluid between cells in the middle layer of skin, for further study. Painless and minimally invasive, the needles can be left in for hours, enabling constant sampling of biomarkers to monitor and diagnose health conditions ranging from dehydration to life-threatening sepsis. A study conducted by Sandia and the University of New Mexico investigated needle length and compared interstitial fluid to blood. Interstitial fluid may someday join blood and urine as a fluid routinely tested for clinical diagnoses. (8600, LDRD)

The SolidSense Gas Analyzer on a Chip robust sensor platform combines electrochemical sensing techniques with neural network machine learning to demonstrate the first small, low-cost, high-temperature stable, on-vehicle sensor that detects and characterizes all EPA-regulated automobile gases emissions with unprecedented parts-permillion- level sensitivity. The device enables continuous optimization of combustion chemistry, control of catalytic converter chemistry, and monitoring of exhaust chemistry at the tailpipe. The platform can also be modified to monitor ambient air quality, characterize the chemistry of power plant smokestack emissions, detect explosives compounds, and address numerous other sensing challenges.

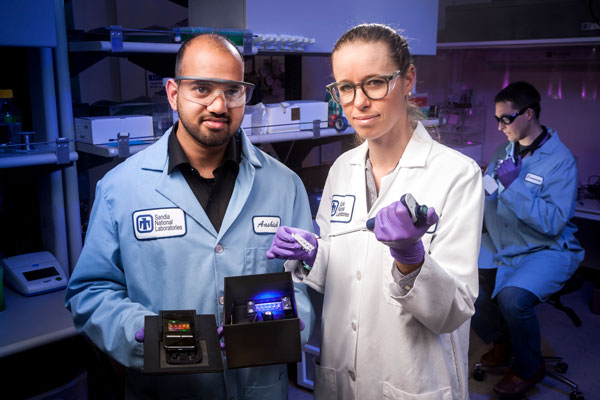

Last year, Sandia developed a lightweight, inexpensive, smartphone app-controlled device that could detect a variety of infectious diseases in less than half an hour. This year, the team added even more capability to their mobile diagnostic device. Now, users can watch the test develop in real time, so they can see the results as they turn positive. In theory, this allows a scientist to estimate the amount of pathogen present in a sample — and help the medical community quickly prepare an appropriate course of treatment. (8600)

Can one of California’s largest and most polluted lakes become its most productive and profitable? To find out, Sandia is testing an algae-harvesting system that uses water from a tributary to the Salton Sea. The sea contains elevated levels of nitrogen and phosphorus from agricultural runoff that algae thrive on. The algae feed on and remove chemicals in water as it passes through the system and back into the sea. The project could yield renewable energy while providing a safe process for removing harmful chemicals.

Sandia organic glass is a new class of scintillation material for radiation detection. It has the uncommon ability of being able to distinguish between incident gamma or neutron radiation with high selectivity. This discrimination ability is key for distinguishing between ubiquitous sources of gamma radiation and Special Nuclear Material such as plutonium-239 and uranium-235. Sandia glass can be formulated with various additives, melted, and cast into almost any shape, including thin fibers.

Sandia’s engineering team has designed, modeled, and tested a control system that doubles the amount of power a wave energy converter (WEC) can absorb from ocean waves, making electricity produced from wave energy less expensive. The team applied classical control theory, robotics, and aerospace engineering design principles to improve the converter’s efficiency. Engineers from Sandia’s Water Power program are using a combination of modeling and experimental testing to refine how a WEC moves, responds, and survives in the harsh ocean environment to capture wave energy. (8800, 6500, 6500, 1300)