Annual Assessment Report

Sandia President and Laboratories Director Jill Hruby signs the Annual Assessment Letter.

One of Sandia’s most high-profile responsibilities to the nation by law is to annually assess the safety, reliability, and performance of the nation’s nuclear stockpile and report the results through our customers to the president of the United States. This year’s successfully executed approach incorporated significant improvements in the processes, content, and clarity of messaging to ensure critical facts and issues were communicated, while engaging all key organizations including weapon systems, components, surveillance, science, and others to inform the relevant national reviews and the Labs director’s letter.

Sandia is leading the execution of Nuclear Enterprise Assurance (NEA) requirements across the Nuclear Security Enterprise through leadership of the NEA Integration Working Group, which addresses implementation interfaces across all labs and plants. NEA protects the modernization programs and the enduring stockpile during the entire life cycle from potential denial of use risks through Weapon Trust Assurance and Supply Chain Risk Management. A robust R&D pipeline supports technology development. Partnerships with Mission Support organizations including logistics, purchasing, information management, and cybersecurity are critical to Sandia’s success. (500)

The B61-12 Life Extension Program was authorized for transition into Phase 6.4, Production Engineering. This authorization is the culmination of multiple successful key deliverables demonstrating baseline weapon design performance, including the System Baseline Design Reviews, several dozen subassembly and Component Baseline Design Reviews, three development flight tests, more than 40 system and subsystem ground tests, publication of a Preliminary Weapon Development Report, and positive feedback from the Preliminary Design Review and Acceptance Group. (200, 400, 1000, 2000, 3000, 5000, 8000, 10000)

Risk Assessment Methodology

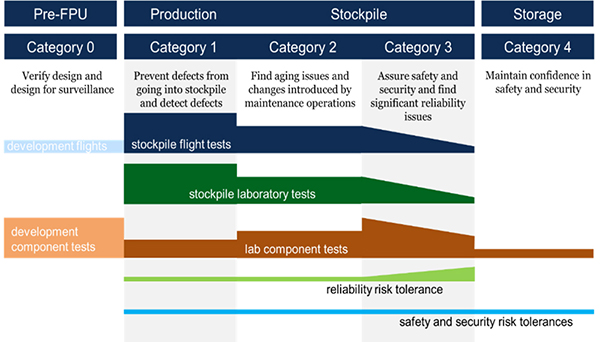

An integrated team developed a new methodology of risk-informed, system-specific surveillance objectives for prioritization of Sandia’s nuclear weapon stockpile assessment work. Requirements were documented in system-specific Integrated Stockpile Evaluation Plans (ISEPs). The objective of this effort is to detect defects and develop the capability to forecast potential technical risks that could impact safety, security, and/or reliability of the stockpile. This new approach will drive efficient use of resources while providing earlier indication of stockpile concerns. The initial implementation of this effort culminated in this year’s annual assessment presented to the Laboratories director. (400, 1800, 2200, 2900, 8200)

In meeting Sandia’s commitment to ensure adequacy of nuclear safety design throughout the product realization process, the Independent Assessment team completed an assessment of the B61-12 LEP and W88 ALT Weapon Project Teams’ Baseline Designs. Follow-on management reviews of both the Nuclear Safety design and assessment results were conducted with the chief engineer of nuclear weapons and the executive VP of National Security Programs, resulting in jointly signed memorandums to the Labs director documenting the adequacy of both systems’ nuclear weapon safety baseline designs. (400)

Eight surety mechanisms under development for the B61-12 LEP and W88 ALT 370 have completed their last development build and are now moving forward into production process prove-in. All are designed to protect the system during an accident or unintended event. These components are sophisticated, custom-designed devices encompassing more than 700 unique parts and assemblies. Group 2610 has design responsibility with invaluable support from Science & Technology, Surety Engineering and Analysis, Stockpile Resource, Business Management and others. (1500, 1800, 400, 2900, 1300, 10600)

The System Interface Tester

Testing engineer Dave Clements uses SIFTer to prepare for a B61-12 flight test. (SIFTer connected to B61-12 test body)

The System Interface Tester (SIFTer) is an innovative software-based Nuclear Weapon testing solution for the Code Management System and has expanded capability to provide critical support for the B61-12 LEP. SIFTer emulates 24 unique hardware and software products of the use control system to support the B61-12 and CMS teams. SIFTer is used during engineering development and qualification to verify critical interfaces and internal functionality. The B61-12 and CMS programs rely on SIFTer in environmental testing as well as aircraft ground and flight tests. (2200, 6900)

The Final Design Review at the SP1115 level for the W87 Alt 360 Gas Transfer System (GTS) Product Realization Team was successfully completed Aug. 23-25, 2016. The design review panel included five members from Sandia and one member from Kansas City National Security Campus. The Alt 360 PRT was applauded for the quality of the review, the great job managing the project, and the teaming among Sandia, Kansas City National Security Campus, and Savanah River National Laboratory/Savannah River Site. On schedule to deliver the First Production Unit in October 2018. (8200)

In a multi-laboratory collaboration, experiments at HERMES III provided insight into gamma ray-driven air breakdown, photoemission, and electrical coupling, and thereby validated source-region electromagnetic pulse code predictions and validated the generation and propagation of prompt signals of interest for a variety of missions (Teller light, gamma rays, and electromagnetic pulse). More than 30 shots were conducted in the most heavily diagnosed experimental series ever recorded on HERMES III. The team received an NNSA Defense Programs Award of Excellence. (1300)

New Capabilities for Hostile Environments

The New Capabilities for Hostile Environments Grand Challenge Laboratory Directed Research and Development (LDRD) project developed new X-ray and neutron test platforms with enhanced capabilities for NW-relevant radiation effects science testing. The platforms opened new avenues for survivability testing and enabled the exposure of NW-relevant devices to higher neutron fluences and higher photon energies and fluences than ever before. The platforms were designed to ensure survival of the test devices and to be coupled with advanced diagnostics that provide a high fidelity characterization of the temporal, spatial, and energy-dependent radiation environment. (1000, 2000, 4000, 5000, 6000, 8000)

The first image shows the TTR Test Operations Center near completion. The next frame is a test asset in flight, milliseconds before impact. The final frame is a graphic of the fiber being trenched in the route around the range.

Tonopah Test Range completed significant improvements supporting surveillance and development testing in FY16. The Test Operations Center was outfitted with new electrical, environmental, plumbing, and fire protection systems, as well as exterior corrosion control and painting. TTR executed eight surveillance and developmental flight tests and developed new procedures for future operations. TTR also completed a joint fiber optic installation of 59.5 miles of high-speed fiber, connecting 40-plus locations over 280 square miles of ground space, enabling the integration of four newly acquired remote sensor systems. (1000, 2000, 4000, 5000, 8000)

Impact test success

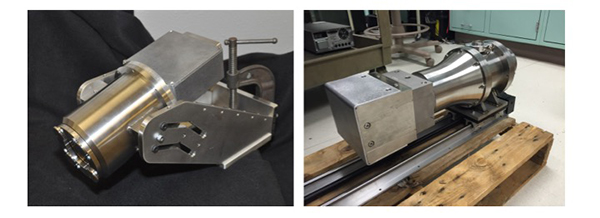

Sandia’s 10,000-foot sled track was used with a high fidelity test unit to provide a representative accident impact condition for evaluation of B61-12 system safety theme integrity.

The B61-12 Life Extension Program successfully executed the Impact1 qualification test to evaluate the ability of the system safety theme to maintain a safe weapon configuration in a limiting accident scenario. The test occurred at Sandia’s rocket sled track facility using a high-fidelity B61-12 configuration coupled with full-system, solid-mechanics modeling to evaluate multiple aspects of the system safety theme. The event successfully captured weapon response data and demonstrated effective safety theme performance using representative hazards to properly simulate a weapon accident. (400, 1000, 2000, 4000)

In FY16, the Primary Standards Laboratory performed calibrations on more than 13,000 individual pieces of test equipment for Sandia line organizations and more than 1,500 primary standards for the Nuclear Security Enterprise. This equipment is used for traceability of more than 75,000 measuring instruments across the complex. The quantities represent an increase of 40 percent, supporting all aspects of Nuclear Weapons modernization, research, development, and Strategic Partnership projects. In addition to meeting the increased workload, the PSL reduced turnaround time for customers and provided critical measurement engineering support. (2500)

Sandia was tasked to design and implement active vehicle barriers at a NATO facility. The barriers were installed at the Entry Control Point and at two aircraft taxiway gates. Sandia completed the barriers in January 2016. The system underwent Government Acceptance Testing (GAT) in March 2016. After the GAT was completed and accepted, the system was turned over to the Air Force, resulting in improved security to US overseas assets. (6500)

Aircraft is loaded with B61-12 Compatibility Test Units prior to ASIC risk-reduction captive-carry flight testing at Eglin Air Force Base, Florida, in June 2016.

Sandia’s Aircraft Compatibility team successfully completed multiple aircraft tests to prove the B61-12 LEP’s application-specific integrated circuit (ASIC) product design. The rigorous test scheme included waveform capture, laboratory testing, ground testing, and captive-carry flight testing on all required aircraft. The team’s efforts yielded vital performance information prior to a “freeze” of the B61-12’s ASIC hardware. This critical risk reduction effort preserved B61-12 program resources by aggressively validating ASIC design and proper function within the weapon system. (2100, 2900)