Ducted fuel injection promises cleaner combustion

An engine innovation first conceived and tested by Sandia scientists has attracted the attention of big business because it synergizes with renewable fuels and takes almost all the soot out of a diesel engine’s exhaust without sacrificing performance or increasing cost.

Ducted fuel injection, developed by Chuck Mueller at Sandia’s Combustion Research Facility, is able to fine-tune the amount of diesel used in an engine to the point of eliminating between 50 and 100% of the soot.

The birth of ducted fuel injection

DFI was first conceived by Chuck from — of all things — a Bunsen burner like those found in almost every high school science classroom in the nation.

“If you unscrew the tube on a Bunsen burner and you light the gas jet, you get a tall sooty orange flame,” Chuck said. “Turn off the gas, screw the tube on and re-light the burner. Now you get a nice, short blue flame right at the end of the tube. The flame is blue because there isn’t any soot.”

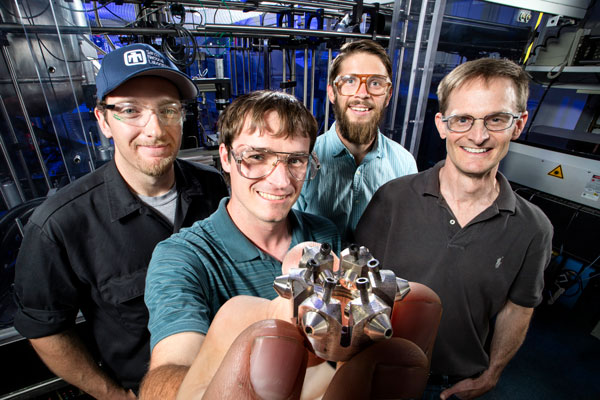

Chuck thought that concept might be adaptable to combustion engines, so he and his team, Christopher Nilsen, Drummond Biles and Nathan Harry, began experiments that have now resulted in an assembly of four to six small tubes, or ducts, directing fuel mixture from the injector right to the points of ignition.

Chuck said that injectors in a traditional diesel engine create local mixtures containing 3-10 times more fuel than is needed for complete combustion.

“When you have that much excess fuel at high temperature, you tend to produce a lot of soot,” he said. “Installing the ducts enables us to closely approach what we call ‘leaner lifted-flame combustion’ — diesel combustion that doesn’t form soot — because the local mixtures contain less excess fuel.”

That keeps the vast majority of the soot produced by traditional diesel engines from even forming.

Emissions balancing act

Generations of engine designs have failed to take soot out of emissions because there was a physical limit to the chemistry of fuel combustion.

“Soot is second only to carbon dioxide in climate change, and it’s toxic, so its emissions should be minimized,” Chuck said. “In the past, there’s always been this problem called the soot/nitrogen oxides trade-off. That is: when you do something to lower soot, emissions of nitrogen oxides — or NOx — go up, and vice versa.”

Nitrogen oxides are also atmospheric pollutants, and the soot/NOx trade-off meant that truck, car and equipment makers couldn’t meet current legislated limits without adding exhaust-gas aftertreatment systems (analogous to catalytic converters on spark-ignition engines, but significantly larger and more expensive). But remove one of those pollutants almost entirely — like DFI does with soot — and Chuck said you have changed the game.

“Now that we’ve got soot out of the way, there’s no more soot/NOx trade-off,” he said. “So we can add dilution — taking some of the engine exhaust and routing it back to the intake — to get rid of NOx without soot emissions becoming a problem. It’s like a two-for-one deal on reducing pollutants.”

Chuck said that in engine experiments, his team has observed simultaneous, orders-of-magnitude reductions in soot and NOx.

“This gives us a path to much lower emissions for diesel engines, solving a long-standing problem for this highly efficient technology,” he said.

Renewable answer

The startling near-elimination of soot and NOx may also open up the market for renewable fuels.

“Not only are the emissions dramatically lower, this combustion approach is truly synergistic with renewable, sustainable fuels, many of which are oxygenated,” Chuck said. “That is, they contain oxygen bonded within the fuel molecule.”

Chuck said that the synergies between DFI and oxygenated fuels should create a stronger market pull for emerging renewable fuels.

“Using oxygenated fuels with DFI lowers emissions more than DFI with conventional diesel fuel, perhaps enough to enable a less-expensive engine system because less exhaust aftertreatment would be required,” he said.

“On a modern on-highway truck, aftertreatment amounts to about $12,000 in initial and operating costs over the life of the vehicle. Reducing even a fraction of those costs is a big deal, given the large number of these vehicles and their importance to the economy.”

Engine manufacturers are “starting to show excitement” about DFI, Chuck said. Not only does it work well with conventional diesel fuel, manufacturers shouldn’t need to retool their production processes extensively to use it.

“DFI is also retrofittable onto existing engines,” Chuck said. “This is especially important for large engines, like those in ships or locomotives, where the engines can cost a million dollars or more, and full electrification is cost-prohibitive. A retrofit is relatively inexpensive and could provide substantial emissions benefits right away.”

Paul Miles, manager of Sandia’s engine research program, said the potential impact of DFI cannot be overstated.

“Breaking the soot/NOx trade-off is the holy grail of diesel engine development,” Paul said. “This is an example of the key role of government-supported research — to identify and demonstrate the potential of innovative, high-risk technologies to reshape the landscape for an industry, our transportation infrastructure and our society, and then to work alongside commercial partners to get the technology into the marketplace.”

Two companies, including Ford, recently signed a cooperative research and development agreement with Sandia to help advance the technology.

Chuck is excited about moving this revolutionary breakthrough from the laboratory into production engines.

“DFI shows promise for giving us clearly superior engines for the future,” Chuck said. “It should preserve all of the desirable attributes of a conventional diesel engine but also significantly lower the emissions, which lowers the cost of the engine system because you don’t have to use as much aftertreatment, and it works even better with current and emerging renewable fuels.”

This research was conducted as part of the Co-Optimization of Fuels and Engines initiative sponsored by the DOE Office of Energy Efficiency and Renewable Energy, through the Vehicle Technologies and Bioenergy Technologies offices.