Part of Sandia’s national security mission is ensuring that nuclear weapons never function unless authorized to do so by the U.S. president. Safety mechanisms in each weapon prevent energy from passing through by accident. However, some conditions a safety mechanism may experience, such as vibration, could cause parts to rub together, leading to wear and reduced reliability.

A team of researchers at Sandia built HPC models that can predict how much wear nuclear weapon components, including the subcomponents that make up the safety mechanisms, will experience over time in a specified environment.

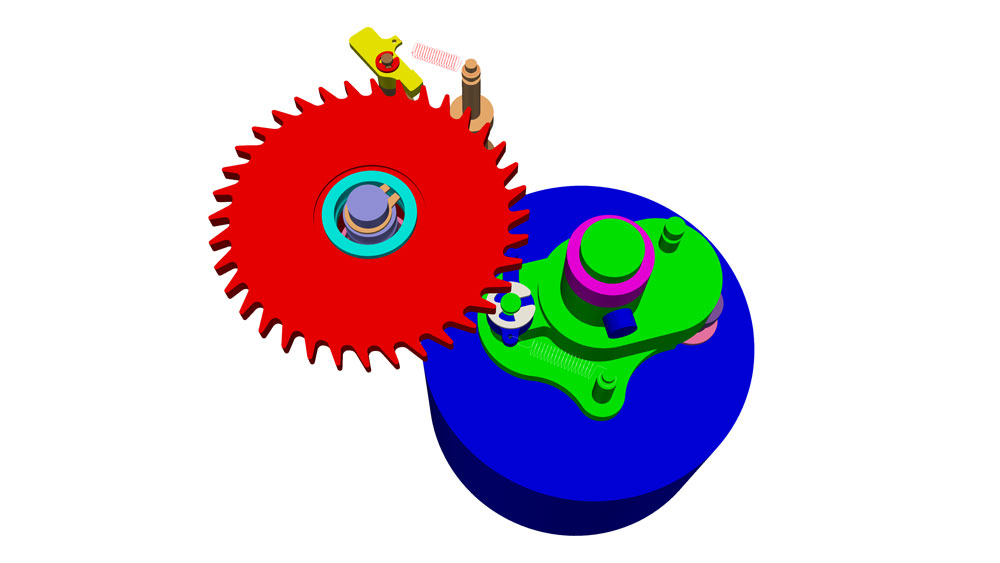

“Mechanisms are an important part of a weapon’s operation,” said Jennifer Fort, project lead and mechanical engineer. “If certain parts within a component wear too much, they may not function as intended, which means the reliability is not what it should be. This is similar to how components in a watch can rub together and cause damage and wear.”

The team used Sierra Solid Mechanics to simulate the wear rate on various parts in a safety mechanism, modeling contact between various sub-components and springs. This was done for multiple orientations in a specified environment. The simulation modeled a compressed one-second acceleration time history, including acceleration in the x, y and z directions.

Each simulation used 720 processors and ran for more than 75 days.

“We simulated the wear rates so that we could avoid future testing of actual hardware,” Fort said. “We gathered testing data on wear rates for one environment and then compared it with the simulations using www.paraview.org. We observed similar wear patterns and more wear on the same parts in both the test and simulation data.”

The team then simulated wear rates for a new environment that had not been tested, again running simulations for 75 days on 720 processors. They compared the wear rates and patterns to the previous simulations and found similarity between the two.

“This will help us evaluate future environments,” Fort said. “The results showed the ability to predict the wear rates and compare future environments that a mechanism could experience. This work would not have been possible without HPC due to the size and complexity of the models.”