Interlocking metasurfaces are a recent Sandia-invented joining technology that may replace other structural joining methods, such as bolts and adhesives. Much like LEGO® bricks (see Figure 1), they are patterned, modular surfaces that constrain motion between two bodies when assembled into a larger structure. Unlike LEGO bricks, they are designed to sustain high mechanical loads. Each metasurface component precisely attaches and aligns with other metasurface components. The specific component shapes can increase the strength and stability of the individual unit cell as well as the assembled structure. Interlocking metasurfaces can serve as an impermanent joining technology for complex shapes, dissimilar materials, extreme environments in aerospace, civil engineering, micro-robotics and prosthetics.

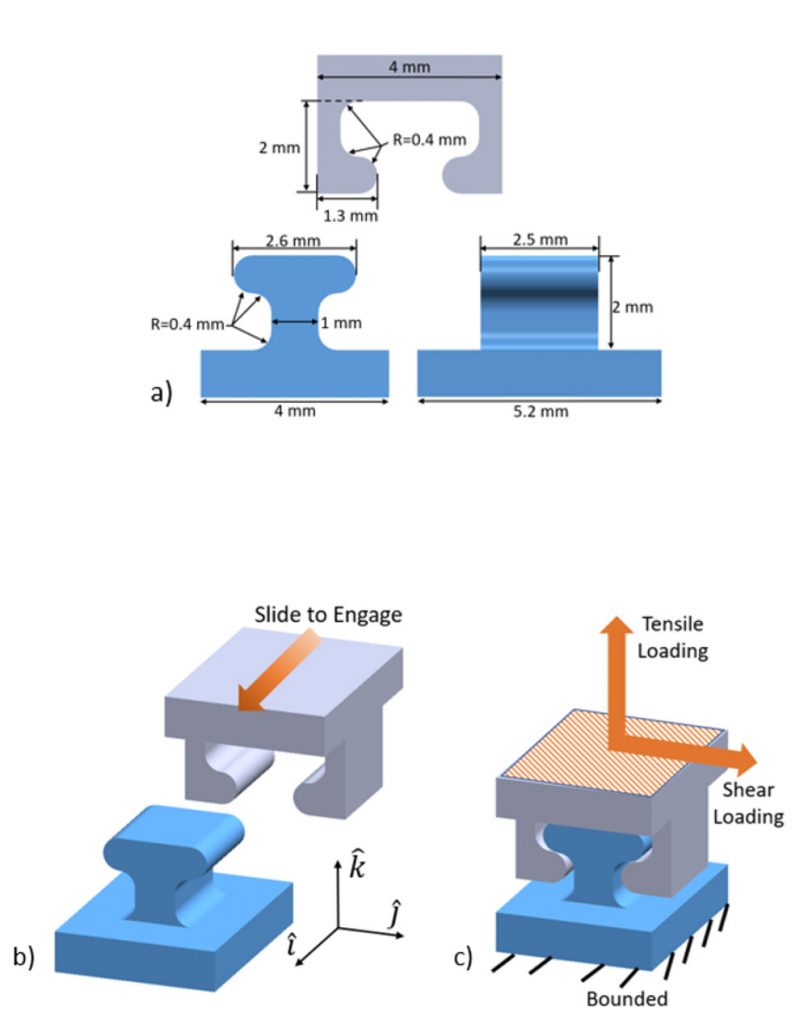

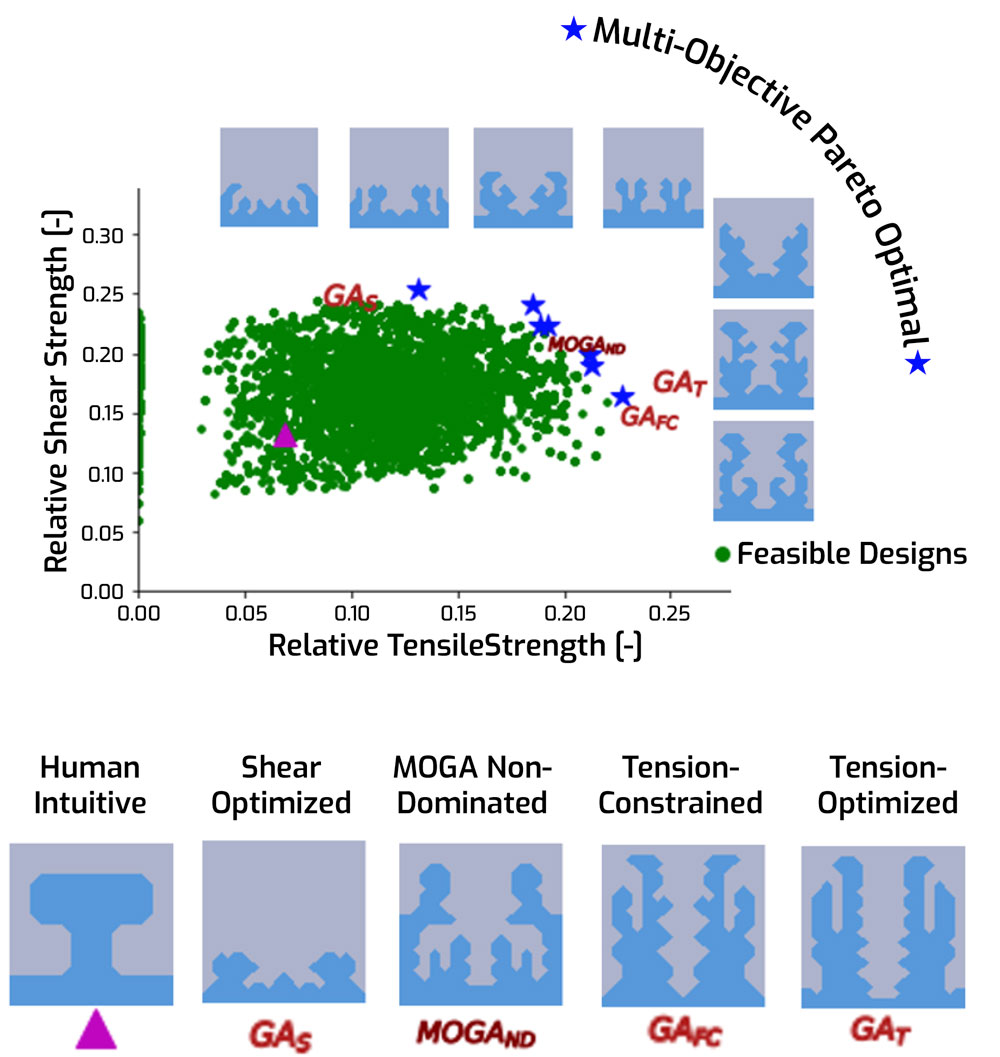

Sandia researchers decided to use machine learning to improve on the human-expert designed unit cells, such as the T-slot, an intuitive design that served as the team’s baseline to compare against their computer designs (see Figure 2).

The HPC computers created training data, which were used to teach machine learning models. The models were then tasked with redesigning this interlocking structure with a focus on vertical strength (tensile loading), horizontal strength (shear loading) or a focus on both. The most promising computer designs were 3D printed and then tested for vertical and horizontal strength.

The vast majority of computer-generated designs performed significantly better than the T-slot baseline. Tall, branching unit cells generally had increased vertical strength and shorter unit cells had increased horizontal strength. Designs that combined both features (such as MOGAND in Figure 3) had both increased vertical and horizontal strength. The team’s data-driven design approaches led to radical, organic-looking designs for interlocking metasurface unit cells. The vast majority of these designs performed far better than prior designs based on expert human intuition. These insights will guide future high-performance interlocking metasurface design.