Modeling software tests numerous scenarios with an eye on assuring nuclear detonations are detected

Since the dawn of the nuclear age, it has been important to know where and when nuclear devices are used. This has led to the development and constant improvement of nuclear detonation detection sensors, work that continues today at Sandia using HPC resources to evaluate sensor performance across a wide variety of scenarios.

Sandia is developing the next-generation optical nuclear detonation detection sensor (SIGHTS). SIGHTS will be hosted on the Global Positioning System satellite constellation and will monitor Earth for nuclear detonations. HPC resources were used both to design the algorithms that operate onboard the sensor and to verify sensor performance as part of two critical program reviews: consent to ship (CTS) and system verification review (SVR).

Most advancements in science and technology come about due to the need to overcome challenges. One challenge for SIGHTS is that laboratory testing of mission performance is limited by the variety and fidelity of optical input signatures and backgrounds that can be generated in a lab setting, as well as the time available to test a range of representative scenarios. HPC simulations can generate much higher fidelity representations of both the input signal and Earth’s background. In addition, the significant computing resources available on the HPC clusters allow a much wider variety of scene conditions to be tested. Mission performance predictions are complicated by SIGHT’s extensive and complex onboard processing, which results in a highly non-linear response. By design, non-linear systems show large changes in output response for a small change in the input stimulus. Examples of such non-linearity include only sending data in response to an event of interest or when a signal exceeds a threshold; this makes it difficult to infer the sensor’s response in cases that aren’t explicitly tested or simulated.

An accurate sensor simulation is essential for overcoming these challenges and predicting sensor performance over a complex mission space. This need was identified early in the SIGHTS program and has led the SIGHTS Modeling and Algorithms (M&A) team to develop a high-fidelity system simulation utilizing HPC resources.

The SIGHTS M&A team includes subject matter experts in the areas of optical system modeling and design, signal and image processing, mathematics, electrical engineering, systems engineering and computer science. Utilizing models developed and implemented by these subject matter experts in combination with software developers, the multi-disciplinary team designed the sensor simulation in tandem with the onboard processing.

Figure 2. Anemone Earth background simulation, including models of the distribution of materials over the surface of the Earth, the complex reflection of the sun off water, clouds, and a model of the SIGHTS optical system. In addition, the simulation includes models of the vehicle orbit and attitude. Note the bright spot about halfway up and halfway from the center to the right edge, showing the reflection of the sun off the ocean

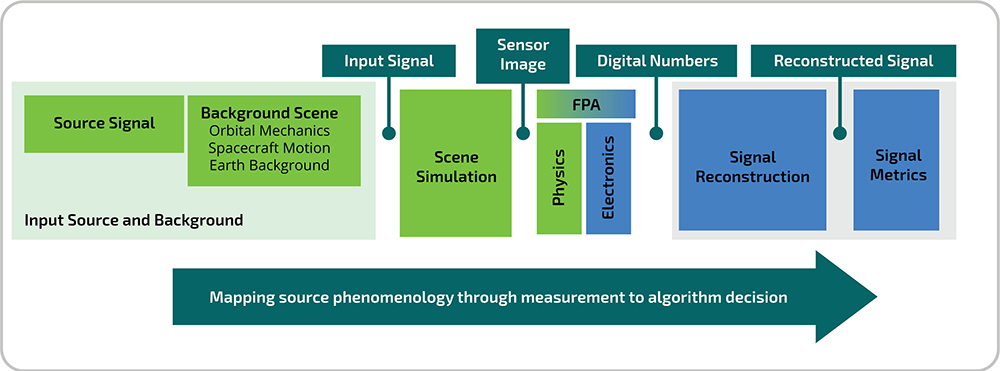

The result was Anemone, a multi-physics simulation code that models the sensor’s view of the Earth and its response to that scene. For the scene simulation, Anemone includes models of Earth’s background, incorporating its natural aspects such as the distribution of materials over the planet’s surface, including clouds and the complex reflection of the sun off water. This is done while keeping other factors in mind, such as host vehicle position and attitude in relation to the Earth and sun, as well as the spectral and temporal optical characteristics of the signature of interest.

Anemone also includes models of the optical system, focal plane assembly and onboard digital signal processing, enabling the accurate prediction of sensor response to the expected on-orbit viewing conditions and signals. The development of Anemone utilized sustainable software development practices, including a robust automated testing suite, continuous integration and continuous deployment (CI/CD) and static and dynamic analysis of source code.

An important and unique feature of the automated testing suite for this code is that it includes a set of tests designed to ensure correlation between the simulation and actual hardware. These practices allowed for rapid development, including direct contributions from subject matter experts and rapid deployment to Sandia’s production HPC environments. The ability to rapidly develop and deploy the simulation code to HPC resources enabled fast, iterative development of the sensor, its algorithms and their operating parameters.

As part of the CTS and SVR reviews, tens of thousands of Anemone simulations utilizing more than 1.1 million node hours across the Stout and Pecos HPC clusters were conducted and evaluated to assess sensor performance against a wide variety of scenarios. The volume of data generated also required HPC-based data post-processing and aggregation to evaluate, summarize and report sensor performance.

The completion of the CTS and SVR reviews would not have been possible without the availability and usability of Sandia’s HPC resources and the support provided by the HPC Operations team.