Sandia serves the nation in developing and delivering leading- edge integrated photonics solutions for our customers and partners in the national security sector.

Our activities range from ground-breaking research through product delivery and qualification with a focus on high performance pathfinder solutions. We leverage the broad capabilities within Sandia’s MESA facility, including our co-located silicon and compound semiconductor fabs, deep R&D expertise, and low-volume manufacturing infrastructure to solve truly difficult problems.

Sandia partners with government agencies, private companies, and universities to collaborate on new technologies, provide expertise, deliver low volume solutions, and transfer technology.

Sandia’s unique capabilities include:

- A staff of > 60 photonics experts skilled in device design, modeling, simulation, epitaxy, device fabrication, integration, assembly, and test

- A 200mm silicon fab with a silicon photonics platform

- A compound semiconductor fab with:

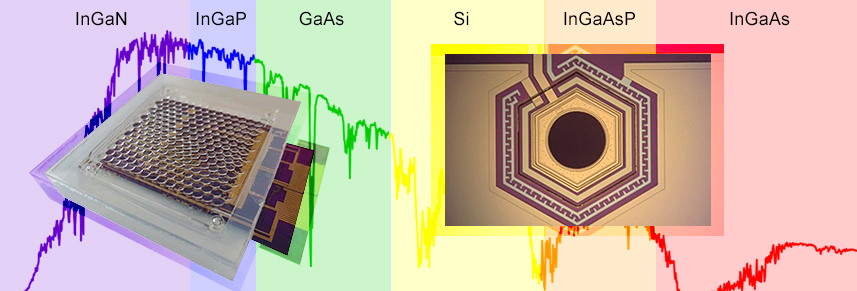

- custom MBE and MOCVD epitaxy capability in arsenides, phosphides, antimonides, and nitrides

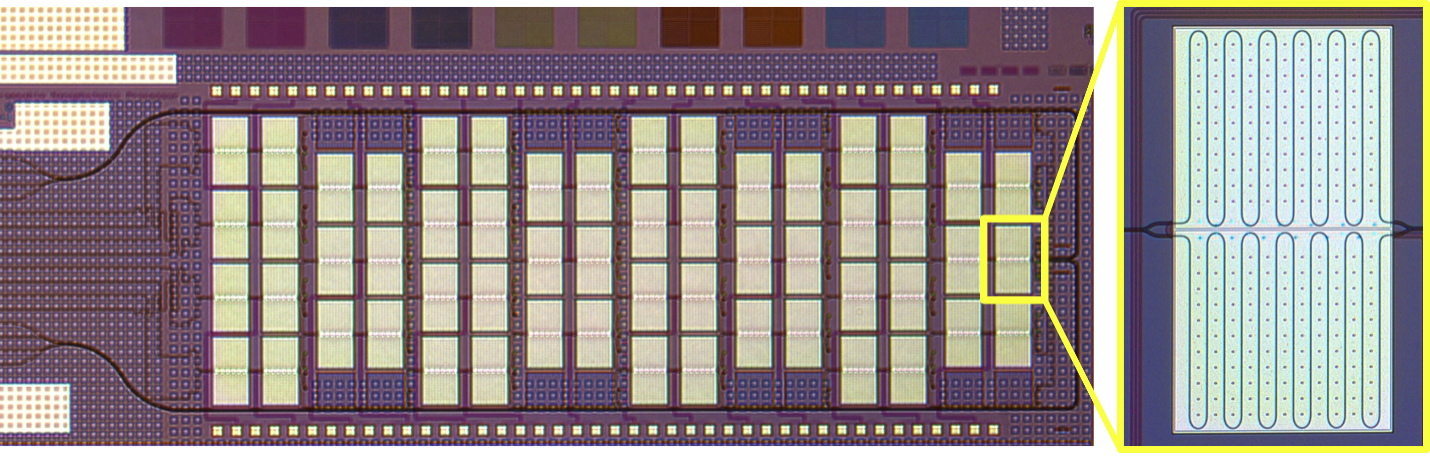

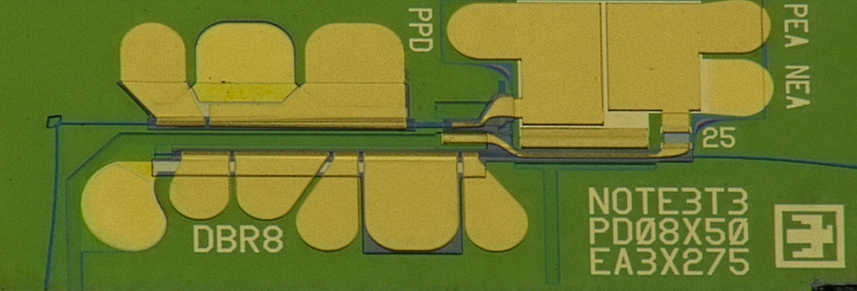

- an InP photonic integrated circuit platform

- Photonic Integrated Circuit Multi-project wafer (MPW) runs in InP Photonics and Silicon Photonics platforms

- Heterogeneously-integrated III-V materials, lithium niobate, piezo-electrics, and other materials onto substrates such as silicon, sapphire, quartz and silica.

- Integrated photonics chips for quantum applications, including computing, sensing, communication, networking, and timing, spanning wavelengths from 320nm to 2.5µm.

- Custom optoelectronic design/simulation including lasers, VCSELs, modulators, waveguides, amplifiers, detectors, photovoltaics, transceivers, focal plane arrays

- Quantum integrated photonics platforms and unique ion implantation capability for quantum devices

- A large toolset for heterogeneous integration, microsystem assembly, and packaging

- Testing and reliability qualification, especially in harsh environments

- Classified and trusted environments available

Areas of Expertise

Capabilities Overview

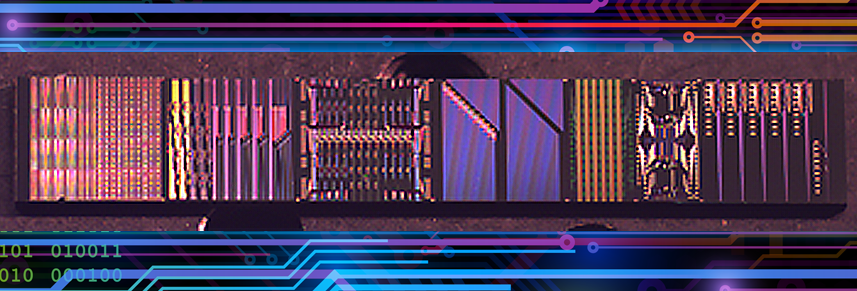

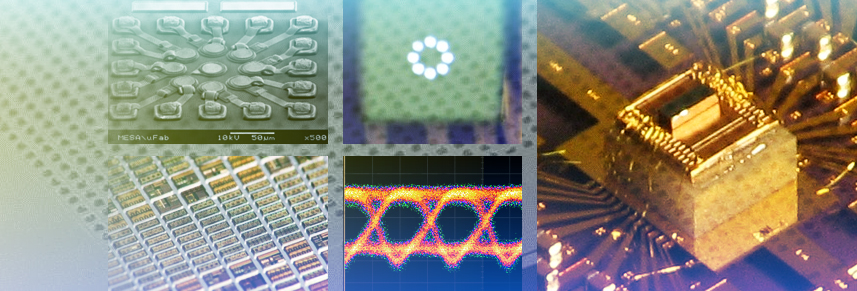

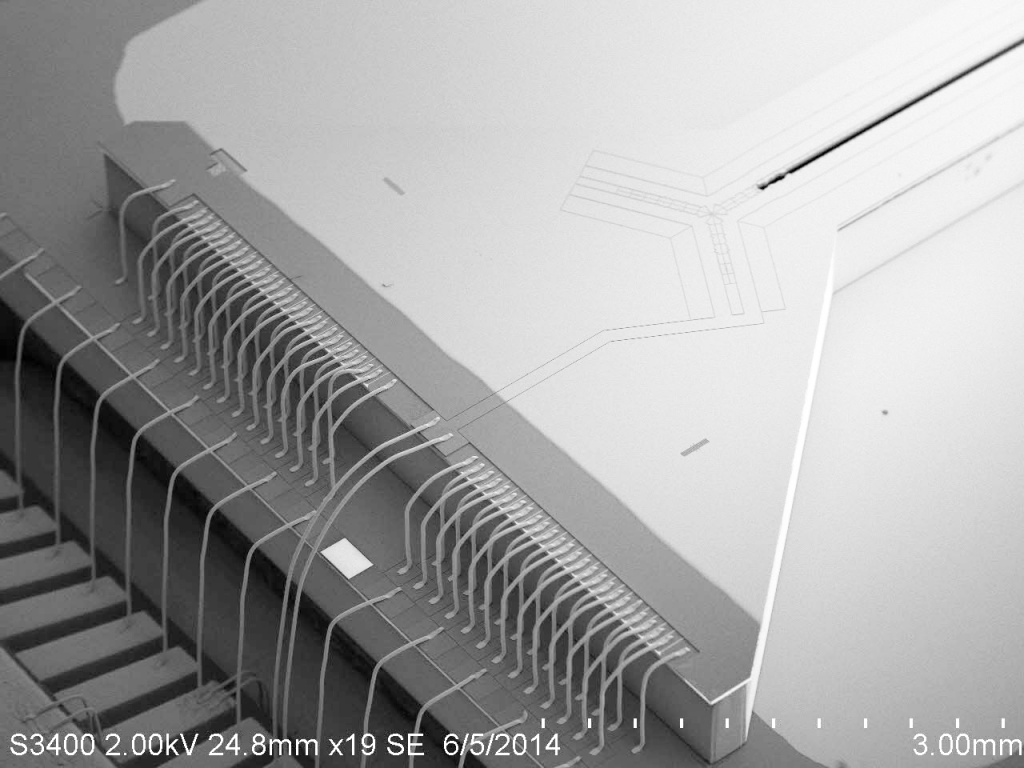

The multi-mission environment of the Labs promotes a diverse, multi-disciplinary team of subject matter experts in fabrication labs and clean room facilities. Two important Sandia support labs – the Silicon Photonic Foundry and the III-V Photonic Integrated Circuit (PIC) Lab – are co-located inside the MESA facility.

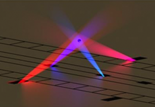

Compound III-V Photonics

The InGaAsP/InP PIC program at Sandia National Labs resides within the MESA facility and is presently used for customer-specific photonic R&D, such as optical data sampling and RF-analog signal processing in the optical domain. Demonstrated capability exists to 40 Gb/s.

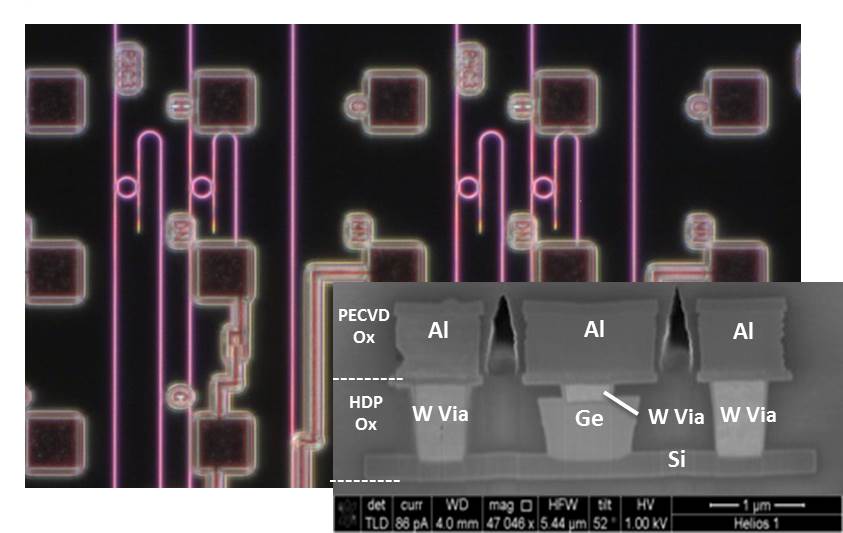

Silicon Photonics

The silicon photonics process is an electro-optical silicon photonic integrated circuit platform built on silicon on insulator (SOI) wafer technology with fully integrated Ge detectors.

Photonics for Quantum

Sandia employs integrated photonics as solutions for quantum technology for communication, sensing, computing, and networking.

Heterogeneous Integration

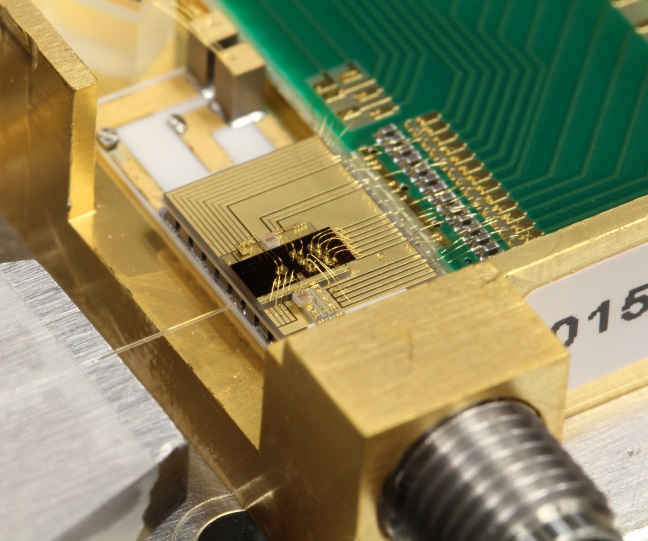

Sandia has unique capabilities in hybrid integration of custom photonic devices and advanced electronic circuits, enabling prototyping of high-performance optoelectronic systems and microsensors.

Advanced Packaging

Sandia experts have decades of experience with the microsystems packaging process, a key step in successful development of integrated systems.

Applications

Sandia’s mission in national security has fostered capabilities and technologies including Photonics, Photovoltaics, Focal Plane Arrays, Advanced Sensors, Optical MEMS, Plasmonics, and Metamaterials.

Failure Analysis, Test, and Reliability Support

Sandia experts invent, develop and utilize different tools and techniques for root cause failure analysis. Sandia supports its customers throughout the product life cycle.

Trust, Classified, ITAR

A fully trusted accreditation status and limited access control process may both be utilized for national security projects via the MESA facility.