Explosives group has developed, tested technology in support of national defense for more than five decades

Last year the US Army began safely destroying stockpile chemical weapons using the Sandia-designed Explosive Destruction System, or EDS, at the Pueblo Chemical Agent-Destruction Pilot Plant (PCAPP). The PCAPP is located at the Army’s Pueblo Chemical Depot, near Pueblo, Colorado, and houses 8 percent of the nation’s chemical weapon stockpile, according to the US Army Chemical Materials Activity.

The EDS was the result of a more than 20-year project, developed and tested by the Explosive Engineering Operations Dept., in response to the need to destroy the US cache of recovered, non-stockpile chemical munitions. The success of EDS in non-stockpile operations has led to its use to address the broader problem of stockpile chemical weapons, including more than 780,000 munitions containing mustard agent that have been stored at the depot since the 1950s.

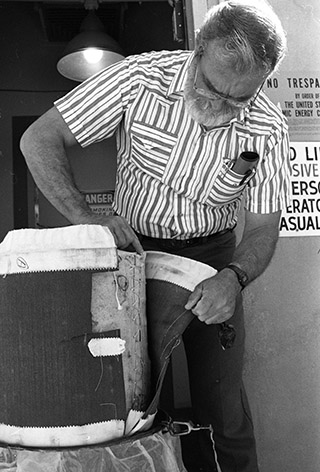

In February, the PCAPP EDS successfully concluded its first campaign, destroying 560 previously over packed problematic munitions, all of which were considered to pose critical safety concerns. Jerry Stofleth, an electrical engineer who has worked in the group since 1985 and is the primary explosive system designer for the EDS, says, “There were a few operational issues that were solved quickly by the integrated Sandia Labs and [pilot plant] team.”

The second phase of the operation is scheduled to start in early 2017. Jerry and his colleagues have continued to work on upgrades to the existing EDS and a new, retrofitted system will be sent to PCAPP in the coming months to support destruction operations.

Beginning in July, the EDS will be used to begin destruction of more than 200 munitions dug out of the ground in Tooele, Utah.

“We are moving and grooving to prepare an EDS for this series of ‘one-off’ operations. Some of these munitions are in a particularly challenging state because they are bent or dirt-crusted,” Jerry says. Tooele is home to the Tooele Army Depot, the DoD’s western region conventional ammunition hub. Operations at Tooele are responsible for the demilitarization of conventional ammunition deemed obsolete in the DoD stockpile or identified as unstable in storage.

20 years of Z

The EDS isn’t the only project that has kept the group busy. The team is working on improving a key component for the Z machine — an ultra-fast explosive closure valve (UCV).

“In recent years, the machine has reached a point where the performance requirements are exceeding what the UCV is capable of providing. We were asked about three years ago to look at the current valve to try to fully quantify it and understand what its performance aspects were. That led to us supporting a new design that we’ve been working on for 18 months,” mechanical engineer Venner Saul says.

Venner says the design has led to a series of parametric studies to quantify what the group worked to accomplish with the valve and what the performance requirements were. The valve has been put through at least 150 tests over the past year and, in the past six months the group has started the next-generation UCV design that will culminate in a new fielded design in about two years.

Small group, vast experience

With just 10 members, Explosives Engineering Operations may seem small but the group has more than 200 years of combined experience at Sandia alone. Members have brought additional years of experience outside the Labs in areas like chemical and mechanical engineering, military operations, and carpentry, heavy equipment operations, and fabrication.

The group also routinely consults with Sandia retiree Paul Cooper, one of the world’s foremost explosives experts. Paul, now a no-fee consultant for Sandia, retired in 1997 after a 32-year career. He started working in explosive components in 1965 and that eventually lead him to the arming and firing group in 1977. Over the years, the arming and firing group, coupled with Paul’s desire to apply robust explosives engineering to nuclear underground testing, became part of today’s Explosive Engineering Operations group. In the past decade, the Arming & Firing Systems and Explosives R&D departments were combined to form one large department under Explosive Systems & Technologies.

Even the group’s facility has been around for decades. It was constructed in 1961 and used as a bunker, storage closet, and armory, among other things, before becoming the group’s permanent home.

“This is the only field testing explosive group at Sandia that has been continuous,” says Neil Altomare, one of the group’s more recent hires. Coincidently, Neil was first introduced, albeit inadvertently, to the group on a battlefield in Afghanistan. It was there that he used the Advanced Personnel Obstacle Breaching System, an improvised explosive device- and mine-clearing tool initially designed by many of the same people still in 5439. At the time of development, the equipment was known as the Small Projected Line Charge.

‘Nuclear terror’ helps build solid reputation

The device is only one on a long list of technologies developed for or in support of the military. In 1979, Paul and other members of the group joined the national Nuclear Emergency Search Team (NEST), and served as weapons disablement experts.

“The arming and firing guys took a good part of the responsibility [of NEST]. They were put together because we were worried about foreign terrorists building improvised nuclear devices and fielding them here. So they picked up all of the arming and firing work for NEST and that also led to the analysis of how the bombs work and how you take them apart and all of the explosive tools for doing that,” says Paul. Because of the amount of work NEST generated, it became a large part of the group’s work at that time.

By the mid-1990s, the group transitioned into an advisory and training role for NEST while the military took the lead.

“That was really a transition for us,” says Jerry. “The NEST program allowed us to transition and to develop more competencies, more capabilities, and more customers, mostly based on reputation.”

It’s that reputation that has brought the group national recognition and praise — and more projects.

Customer-driven

With no shortage of work, the department considers itself to be self-supporting.

“Customers come to us and tell us what it is they want. From there, we characterize what the request is and we get to work. There have been a few occasions where a customer approaches us with their problem on a Thursday and by Monday or Tuesday we’ve built, tested, and re-tested the problem and have a solution,” says Gilbert Gonzalez, an electromechanical technologist who joined the team in 1986.

This was the case, following the Sept. 11 attacks, when a passenger was threating to bring down an airplane with liquid explosives. The Department of Homeland Security asked the FBI to investigate how many ounces of liquid a passenger should be allowed to carry without posing a security risk. The FBI, in turn, got in touch with Sandia’s Systems Research Center (5900) which, on a Thursday, got in touch with Jerry. The group immediately got to work over the weekend, building shells of airplanes and testing the damage that could be done with various amounts of liquids. Following the testing, the end result was 3 ounces, which continues to be enforced today at airports across the country.

This work led to the formation of the National Center of Excellence for Explosives, led by Sandia with participation from Los Alamos and Lawrence Livermore national laboratories. The Department of Homeland Security funded the work for several years following initial testing.

Decades supporting national defense

Explosive Engineering Operations has supported numerous investigations and projects. Here’s a small sampling of those done in support of national security.

Investigations:

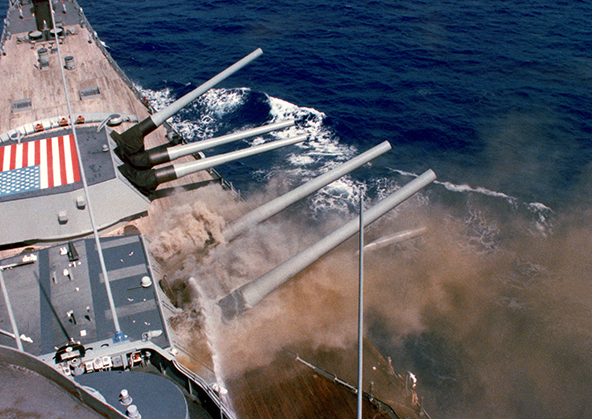

- The April 19, 1989, gun turret explosion on the USS Iowa

- October 1991, United Nations/International Atomic Energy Agency inspection team sent to Iraq to look for evidence of weapons of mass destruction

- The April 19, 1995, Oklahoma City Bombing

- The July 17, 1996, TWA Flight 800 explosion over the Atlantic Ocean

- The June 9, 1998, DeBruce grain elevator explosion near Haysville, Kansas

- Critical infrastructure blast vulnerability analysis following the 9/11 attacks

- The 2005 rocket motor fires at Umatilla Chemical Depot in Oregon

- The 2011 Fukushima Daiichi nuclear power plant reactor failure in Japan Projects

- Flight Termination System for the US Army’s Advanced Hypersonic Weapon (AHW)

- Kinetic Energy Projectile (KEP) warheads in response to the Gulf War

- Improvements to the Individual Body Armor (IBA) used by troops in Iraq and Afghanistan

- Advanced Medium-Range Air-to-Air Missile (AMRAAM) warhead evaluation and modification

- Fuel-air weapons development

- Multiple national security community projects in support of the DoD and DOE

Reputation built on trust, hard work, creativity

The group relies heavily on customer requests and takes pride in the fact it will “never say no” to a project. “Not only will we do it but we will do it better than anyone on the planet,” says Jerry.

The group has won a NOVA award, the highest honor given by Lockheed Martin, and received the Diplomatic Security Service Appreciation Award from the Department of State. “It’s not just the attitude of everybody here — the ‘can do’ philosophy, self-motivation, and desire to learn new things — it’s that fact that we can all work together. There’s not one person here who I don’t consider a friend. If you can’t get along with someone, no matter how smart or competent they are, it’s going to be hard to work with them,” says Jerry.

With all of the hazards the group is faced with on a daily basis, Gilbert says it’s imperative to believe the person to your left or right is doing the right thing. “To some degree you’re putting your life in someone else’s hands,” he says, and he’s done just that thousands of times. Of the 10,000 shots fired by the group, Gilbert has pushed the button on 90 percent of them.

Jerry says the group has been successful because the members trust and respect each other, adding that it helps that everyone in the group is a perfectionist. “It’s not that everyone has an aptitude, it’s that the group itself has an aptitude. It all comes down to doing good work, building a reputation, and having people come around and recognize that you are a national resource,” he says.

For Paul, it’s easy to see why the group continues to thrive, five decades after its launch.

“The guys here are very creative and this group meshes engineers and researchers and developers to make a cohesive group. It’s a group full of good people who are talented, creative, and hardworking. That combination is why they have been so successful.”