Brandon Langdon and his team know they can add something to your project — something you may not be able to get through traditional methods of creating parts.

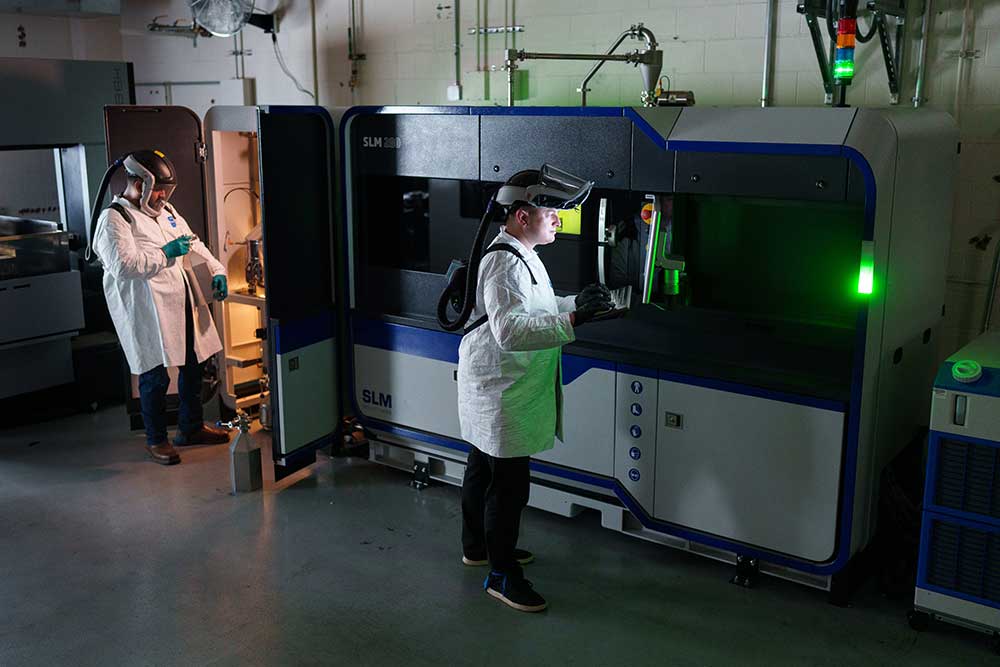

Brandon is one of Sandia California’s electromechanical technologists, which is to say he knows how to 3D print very complex items — items that can be really small, created for a specific use and even made out of metals like titanium.

“We’re doing things that are research-oriented, providing parts in materials that need to be tested, as well as internal parts for complex systems,” Brandon said. “We are characterizing materials and evolving standards for international standards communities like American Society for Testing and Materials International and SAE International.”

A 3D-metal printer works by adding layers of metal powder in a pattern then using one or two lasers to shape the emerging part. Brandon programs laser parameters, designs parts with varying geometry and then figures out how to bring it all together in the machine with the right powder composition. It’s work that requires extensive collaboration with researchers who want to create and test a shape or part.

“There is currently a push from NNSA and Sandia management to use the additive processes in future component designs,” said nanomaterials scientist Josh Sugar, who worked with Brandon and his team on a project. “It is essential that the research and development community partner with the additive materials lab to produce materials and components that can be studied and tested.”

Brandon said the lab has a deep set of applications they can manufacture.

“We can work on materials characterization for chemists,” he said. “There are some materials that we can print that are bio-safe for implanting in bodies, and that’s really interesting. We make connector brackets or things that might be challenging to manufacture. We did a part for researchers who needed a certain texturing on a small area, but it was just too small to machine. We 3D printed the whole part, adding threads and texture where needed.”

Brandon and the additive manufacturing team have helped develop pieces to test hydrogen penetration and degradation of various materials and a host of other work that enables other research teams to move forward quickly, without waiting for a commercial part or having to buy many types of materials. The lab can even produce a thin layer, or coat, of a material for testing.

“One advantage of doing spray coating or electroplating, is that if you have an expensive material or a rare material, you don’t have to get a billet of it and machine it out,” Brandon said. “We can just do a surface coating a few microns thick and then have the rest of it just be some inexpensive steel or titanium that you know is much easier to work with.”

With a new piece of equipment in Sandia California’s additive manufacturing lab — a selective laser melting printer — the team can create intricate designs in titanium. The additive manufacturing process allows the team to produce objects that have open internal channels or optimize an existing design.

“If there was something we’re trying to improve on, like maybe it was just too heavy, I can help take that existing design and very quickly make it lighter,” Brandon said.

Working closely with Sandian colleagues gives the additive manufacturing team better insight into how to solve their modeling and manufacturing issues, resulting in products that are fit specifically for their needs. Josh said part of that collaboration involves learning what is possible.

“We need to understand additive processes at a fundamental level so that we can design and build parts with reliable and predictable properties over their lifetime,” he said. “We also need to be able to write specifications so that our partner production sites are successful at manufacturing parts that meet these requirements.”

Brandon said that they are able to work with groups that aren’t sure exactly what they need.

“If people want to play around with some ideas, we can print 12 small things on the plate at the same time rather than having to machine each one, one at a time,” he said. “We might be able to offer you a quicker and faster way to get closer to a prototype.”

“If everything’s letting you down on the traditional ways of doing things, then additive can pick up a lot sometimes because maybe there’s a reason it’s not working for you in the design space,” Brandon added. “You’re maybe outside of the envelope for traditional manufacturing or maybe your constraints are in such a way that you need to simplify the part.”

Brandon said his team wants to help anyone they can with their research.

“A successful partnership between the additive manufacturing lab and the R&D community enables success in these endeavors,” Josh said.