Sandia nuclear engineer Sal Rodriguez has been working for years to prove that adding dimples to things like rockets, wind turbines, cars, even heaters, makes them more efficient.

Together with the University of New Mexico and graduate student Graham Monroe, Sal’s research is propelling the future of aerospace by infusing rocket science with a touch of golf ball magic, uncovering a groundbreaking aerodynamic revelation with the potential to accelerate space exploration.

The making of the rocket nose

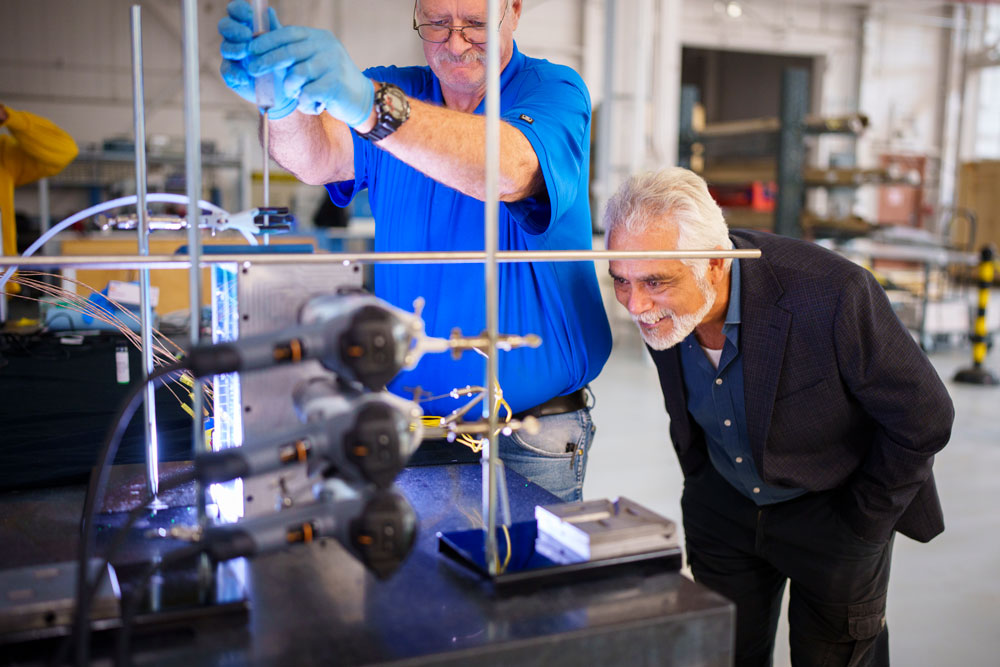

PASSIONATE INVENTOR — Sal Rodriguez answers questions about his dimpled rocket nose from Johann Snyder during an Inside Sandia podcast recording. (Photo by Lonnie Anderson)

Sal’s flashiest work by far is a 15-pound rocket nose clutched under his arm as he walks around Sandia, at conferences and schools.

“I think this will be game-changing,” Sal tells people.

The “this” are tiny dimples, like those on a golf ball, that cover the bright red, cone-shaped rocket nose.

“I was always interested in aerodynamics. I was working on my bachelor’s in engineering degree in 2019 when I took part in the Lobo Launch at the Spaceport America Cup,” Monroe said. “Meanwhile, Sal was researching some dimpling projects. We started talking and came up with the idea of dimpling the nose cone of a rocket.”

The experiment turned into Monroe’s master’s thesis project.

They started with the dimpling program that Sal created in 2014 and copyrighted in 2017.

“The program includes a specific set of equations that allows the user to look at an object’s geometry, add the velocity and the fluid it’s traveling through. You put that into the program, and it outputs the required dimple pattern,” Sal said.

Monroe 3D printed the nose cone while UNM’s Lobo Launch team created the accompanying rocket and a smooth nose cone that was identical, minus the dimples.

Then, they waited.

Due to the Covid-19 pandemic and fact that the Lobo Launch team needed their rocket for the upcoming Spaceport America Cup competition, launching the rocket became a challenge. It was finally put to the test in November and December of 2022. The results were better than they expected.

“We were overjoyed when we found that the dimpled rocket had 22% less frictional drag compared to a smooth rocket. At its peak, it reduced drag by 39.1%. So that’s less fuel you need, and it produces less CO2, which is good for the environment,” Sal said.

Monroe is proud to have been part of the project. “It’s been really neat to be part of this research. To be part of something that could be used in the real world,” he said. “When we look at the day and age that we are in, as far as space exploration, the effect this could have on energy savings is really significant.”

How dimples work

“Dimples generate turbulence, redistribute the turbulent energy, accelerate the flow in the dimpled regions, and reduce the boundary layer thickness,” Sal said.

He said a good analogy is an Olympic diving competition.

“The diver who plunges into the water with the smallest splash gets extra points because only a very small amount of resultant water flow is generated by the more aerodynamic dive,” he said. “The same occurs with dimples. They generate a flow pattern that is so aerodynamic, that only small, disorderly flow currents are generated by the dimpled objects — a gold medal dive.”

Bring in the Mustang

But it’s not just rockets that can benefit from this dimpling. Sal has been exploring other ways to use dimples. In a little-known project with Bobby Unser Jr., Sal dimpled the hood of a Ford Mustang.

“It was so exciting because he was so enthused about racing and race cars,” Sal said of Unser. “I told him about my copyright and that I could dimple his sports car and make it go faster. He was very excited.”

So, Sal did.

He used his program to narrow in on the ideal size and placement of the dimples on the car’s hood. Like the rocket, the results were significant. They showed a minimum 25% reduction in airflow drag compared to a car with no dimples. The experiment also included a car with tennis-ball-sized dimples, to prove that while all dimpling helps, precision with dimples is key.

Whether or not consumers would prefer dimples on their car is another question the pair hoped to explore. Unfortunately, Unser died before the project went any further.

Not just for aerodynamics

One of Sal’s latest projects is using dimples in heat transfer. With the help of funding from the New Mexico Small Business Assistance Program, Sal has built an apparatus that shows how dimples can speed up the heating process.

A box with three sides of Plexiglass and one side of dimpled aluminum is filled with water and then connected to a heat source. “We put beads and dye in there to see how they move along the dimples. We witnessed them accelerate, twice the velocity than outside the dimple area,” Sal said. That proves that the dimpling accelerates heat transfer.

Sal said the technology can be used with solar water heaters. Something that could be life-changing for places that don’t have easy access to electricity, such as rural areas, remote parts of Indian reservations or developing nations.

Sal said a company in another country is already exploring the commercialization of a product like this.

The road ahead

Sal’s dimpling work is far from done. He’s already dreaming up new ideas.

“Any dimple will have a beneficial effect on aerodynamics. We will be able to design rockets that can carry a much heavier payload in space and make space exploration more affordable by at least 10-20%,” Sal said. Sal’s team recently submitted a non-provisional patent application for dimpled wind turbines.

“We can apply to rockets, aircraft, cars, electronic vehicles, submarines, drones, even wind turbine blades. We can extend the distance that they can travel or the energy they harvest,” he said. “Maybe we could do speedboats, jet skis, even frisbees.”