Biotechnologists have developed a new way to use magnetics to expand upon the capabilities originally developed with the SpinDx handheld medical diagnostic tool and quickly diagnose even more diseases and illnesses.

Building upon success

Developed 11 years ago, SpinDx was able to determine a patient’s white blood cell count, analyze important protein markers and process dozens of assays — or measurements of biochemical markers — from a single sample, all in a matter of minutes.

“I had a certain idea in mind for how we might build upon, but also simplify, what had been done with SpinDx,” chemical engineer Robert Meagher said. “In the case of medical diagnostics, you want a rapid response in places where there might be need to analyze a sample quickly — a remote base or a clinic or something like that — and detect the biomarkers of infection so that you can get an early indication of whatever your patient is infected with. If it’s a bacteria or a virus or something else, that can guide very early treatment decisions like administering antibiotics or antivirals.”

Robert hoped to increase the number of tests that can be done by the device.

“The ideas that I had turned out to be pretty hard to implement,” he said, “and that was around the time that Josh was coming on board the project and came up with some really creative new directions.”

Innovation gets personal

Electrical engineer Gihoon “Josh” Choi wanted to work in bioengineering because a family member was hospitalized for months with a disease, in part because testing was so slow.

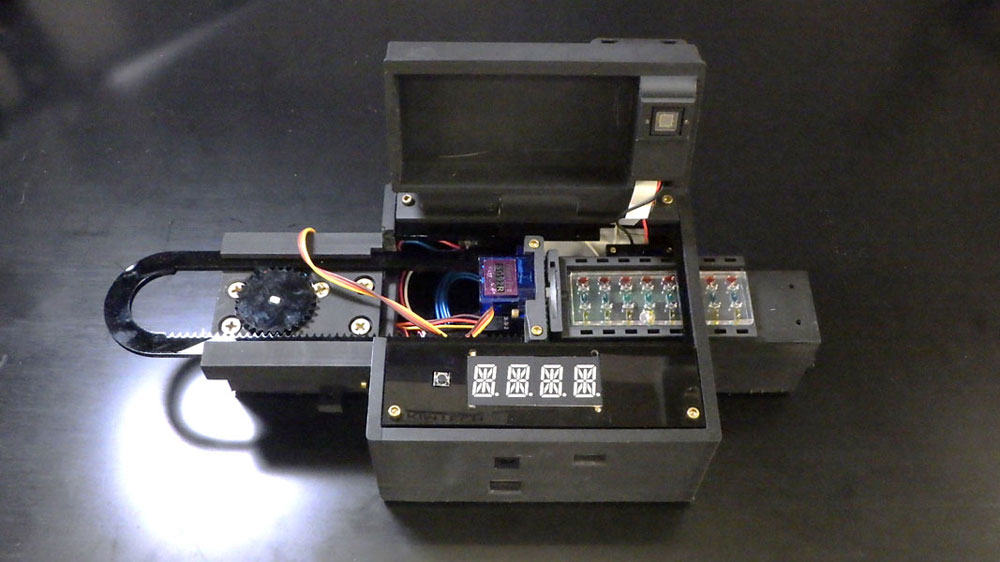

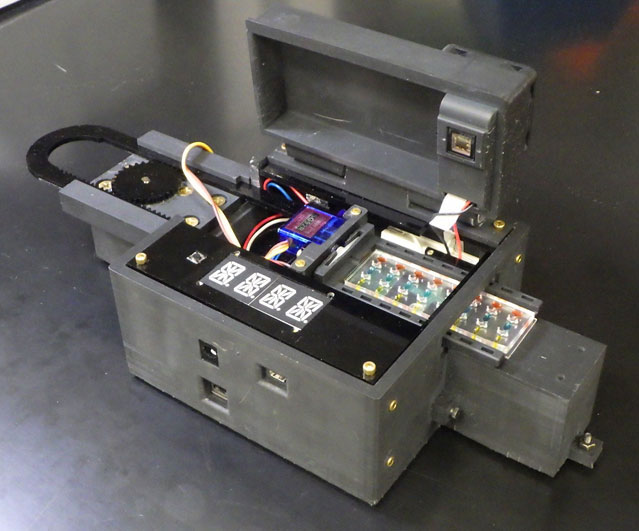

“I wanted to pursue electrical engineering to develop a portable diagnostic system that can be used in a practical setting,” he said. “And I thought a creative approach to handle multisteps of sample process with minimal user intervention is crucial for the advancement of point-of-care technology. So, we came up with the programmable electromagnetic actuator that automates the sample steps.”

Tiny magnetic beads, between 1-5 microns, are used to collect the samples of bodily fluids. The sample clings to the bead, creating a sphere of material that can be tested multiple times.

“In conventional biology methods, it’s very common to just have a little test tube that has the beads, and you just literally put a magnet next to that, the beads collect next to the magnet and then you go in with a pipette,” Robert explained. “The beauty of it is that you can capture something from solution on the bead, hold the bead in place and then change the solution conditions around it to accomplish multistep assay.”

One sample, multiple test steps

Josh figured out a way to use electromagnetism to actuate the tiny beads inside a microfluidic device, where it can be tested in multiple ways with multiple reagents.

“You don’t necessarily want that person who’s running the test to have to stand there looking at their wristwatch or setting a timer for five minutes to add the next reagent. Now, in another five minutes, run a wash step and wait another five minutes,” Robert said. “You really want something where the operator can just add the sample and press go.”

Ten to 15 minutes later, the health care provider can get the result one would get in a home COVID test. Building upon the technology developed with SpinDx, which could only be used for single-step assays, the new platform allows users to wash samples and other intermediate processes, automating more complex testing and higher fidelity results.

“You can repeat that for multiple cycles,” he added. “Instead of a person putting the tube of beads next to a magnet, using a machine that takes up a lot of laboratory space and has $100,000 or more worth of robotics, you can perform the test where the care is actually needed.”

Through funding from the Laboratory Directed Research and Development office, Josh built a prototype. Sandia is now seeking commercial partners to share the technology with. Robert and his team are working on adding to the toolkit of what Sandia can implement with the electromagnetic array, including temperature-controlled incubations.