Noise modeling researchers’ latest project in 30 years of Sandia and Goodyear collaboration

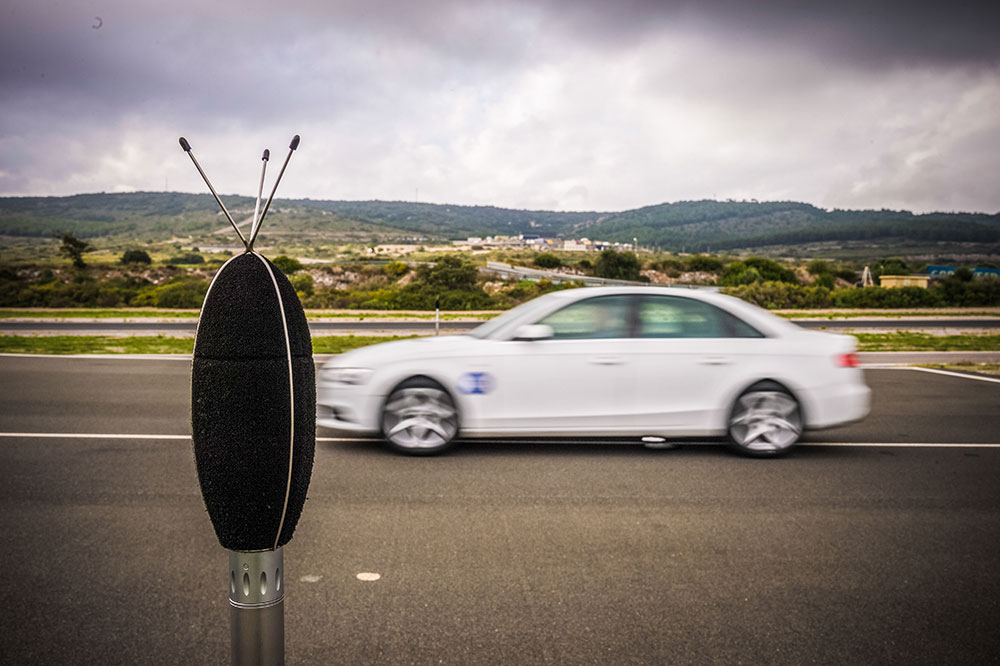

Sandia and The Goodyear Tire & Rubber Co. have developed a virtual way to test how noisy a tire will be on the road without the need for physical testing, leading to quieter tires for electric vehicles.

This project is the latest to come from Sandia and Goodyear’s 30-year partnership, formalized through a Cooperative Research and Development Agreement, or CRADA, that focuses on collaboration between the national lab and the last U.S.-owned tire and rubber company in advanced mechanics, data science and rapid response tasks.

As more electric vehicles come to the market, drivers and car companies are noticing tire noise more than before, said Michael Skroch, manager for simulation and modeling science at Sandia. In gas-powered cars, noise predominantly comes from the engine, exhaust and muffler, but tires tend to be the loudest noisemaker for electric vehicles.

“Developing products for commercial, consumer and off highway segments that are equipped for the demanding needs of electric vehicles and balance the performance requirements desired from a growing audience of adopters, is a major focus for Goodyear,” said Brandy Moorhead, director of Government Compliance and Product Performance at Goodyear. “Our modeling work with Sandia is enabling us to design tires to help reduce the level of interior vehicle noise while also minimizing the need to test and model multiple physical prototypes.”

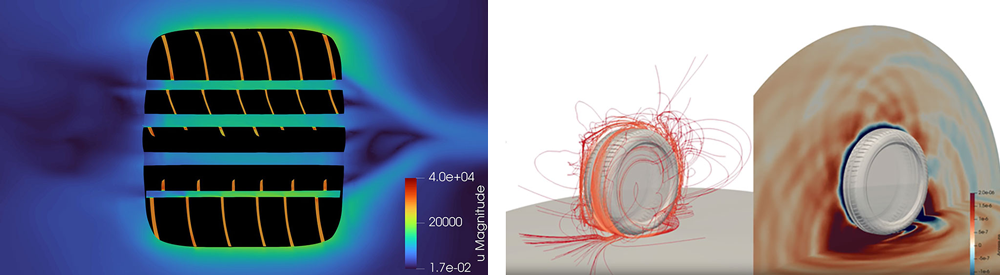

Modeling how much noise a tire will make when it makes contact with the road is a mathematical multiphysics problem, as are the scenarios Sandia runs for its nuclear deterrence mission, and these are complex, computationally and memory-intensive simulations, Michael said.

In the past, Sandia started simulating one aspect of physics at a time, such as looking at how a bomb shakes in flight, how heat moves through it or how air moves around it. This gave researchers an understanding of one element an object will experience in flight, but it didn’t provide a complete picture on its own. Then researchers started linking the simulations one after another, modeling the physics step-by-step. Now, Sandia has a powerful suite of codes that can run these simulations together, providing a more holistic, multiphysics picture, which helps Sandia certify the safety of weapons and that they will never work unless authorized by the president to do so.

By switching out the material properties and other inputs, these same codes can model how much noise a tire tread design may produce.

Gregory Bunting, Sandia’s technical lead for the Goodyear partnership, said the simulation models how the weight of the vehicle pushes the tire onto the road, causing the tire to deform. It then models the tire rolling down the road, looking at friction and airflow. As air moves around the tire, it gets squeezed in and out of the treads, which produces noise, much like a musical instrument.

“The challenge of simulating tire noise is driving us to solve new important multiphysics problems that help Goodyear virtually design quieter tires, and then those same methodologies can be applied to help Sandia do better simulations for nuclear deterrence and national security,” Michael said.

Moorhead said this research has supported Goodyear in its development of tires that help minimize road noise as well as help facilitate work with car manufacturers requiring virtual tire models and modeling results in place of physical test results.

“While Goodyear and Sandia differ significantly in our missions and objectives, this partnership is a win for Sandia, a win for Goodyear, a win for national security and a win for U.S. economic competitiveness,” said Mary Monson, senior manager of business development at Sandia. “This partnership has centered on the insight that advanced modeling and predictive simulation is a powerful tool for characterizing physically complex processes and can be brought to bear on a surprising range of applications.”