Sandia’s Weapons Evaluation Test Laboratory simulates everything a weapon would experience

Larry Kuykendall doesn’t expect everyone to love Amarillo, Texas, but he does.

“People that live here love it,” said Larry, who was raised in Dumas, Texas, about 45 miles north of his current home in Amarillo. “A big part is the people and how friendly people are. Amarillo is big enough so you have city life, but then it’s like a small town… Cooler, dryer summers than Dallas… People take pride in what we do.”

What Larry does, along with his colleagues at Sandia’s Weapons Evaluation Test Laboratory, is ensure that the United States’ stockpile, including newly developed weapons like the B61-12 and the W88 Alt 370, works as intended.

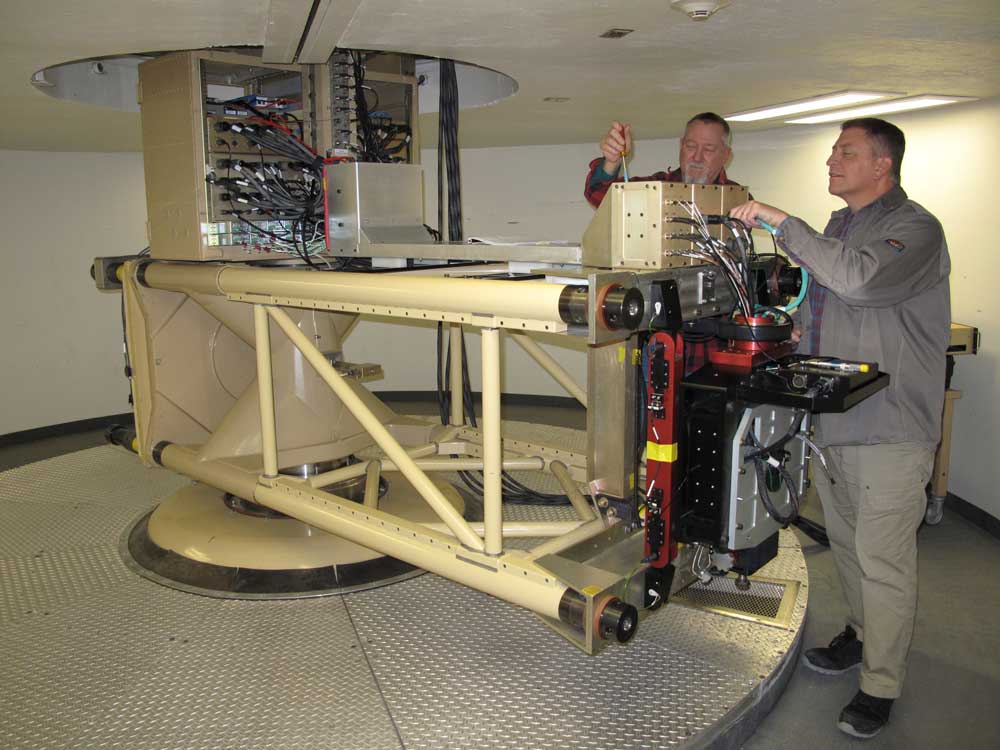

Located at the nuclear security enterprise’s Pantex production facility, the testing laboratory puts the non-nuclear components of bombs and warheads through their paces, simulating everything they would experience from launch through impact, and capturing and analyzing more than 1,000 channels of data that provide a detailed picture of the weapon’s performance.

“Our job is to find anomalies,” said Larry, a team lead at the testing lab. “We’re not hoping for a failure, but if there’s an issue, it’s important that we address it before it becomes an issue out in the stockpile.”

To simulate the actions and environments a warhead would experience, from the mind-bending acceleration of a missile launch through the instant stop at target and the series of extreme environments in between, the Weapons Evaluation Test Laboratory leverages several rare capabilities. Shaker tables vibrate the system, temperature chambers ensure it works far below freezing and well above the melting point for many materials, and centrifuges accurately simulate the weapon’s entire flight path.

While the testing requires long days to conduct pretest calibrations, run the test and finish post-test calibrations, the lab’s four 10-hour days per week schedule affords staff a level of work-life balance.

The testing lab also provides constant opportunity for professional growth.

“You can learn something every day here,” said team lead Brandon Hill, who had just earned his engineering degree from Amarillo College when he answered a newspaper ad to work at the weapons testing lab in 2002. “Our systems are so complex, it takes years and years to learn. If you’re not learning, you’re not trying.”

Between surveillance to ensure current stockpile assets remain viable as they age and planned testing for future additions to the nuclear deterrent, like the W80-4 and W87-1, the team expects a high volume of activity for the foreseeable future.

“We’re booked to the end of the decade,” said manager Suzanne Helfinstine, who graduated from Texas A&M University and joined Sandia after gaining experience at several nuclear security enterprise sites.

To meet the need for this work and mitigate risk as the lab’s singular infrastructure ages, the NNSA is funding an additional new centrifuge and corresponding expansion. The lab is also seeking funding for space to host new testing equipment that will be needed as the W80-4 program progresses.

Brandon appreciates the larger purpose of the testing lab’s work.

“Our job is to find the reliability of the system,” he said. “It’s important to determine that now, so America and our allies can be confident in our nuclear deterrent.”