Freddie Hidalgo recounts his time working on underground nuclear weapons tests

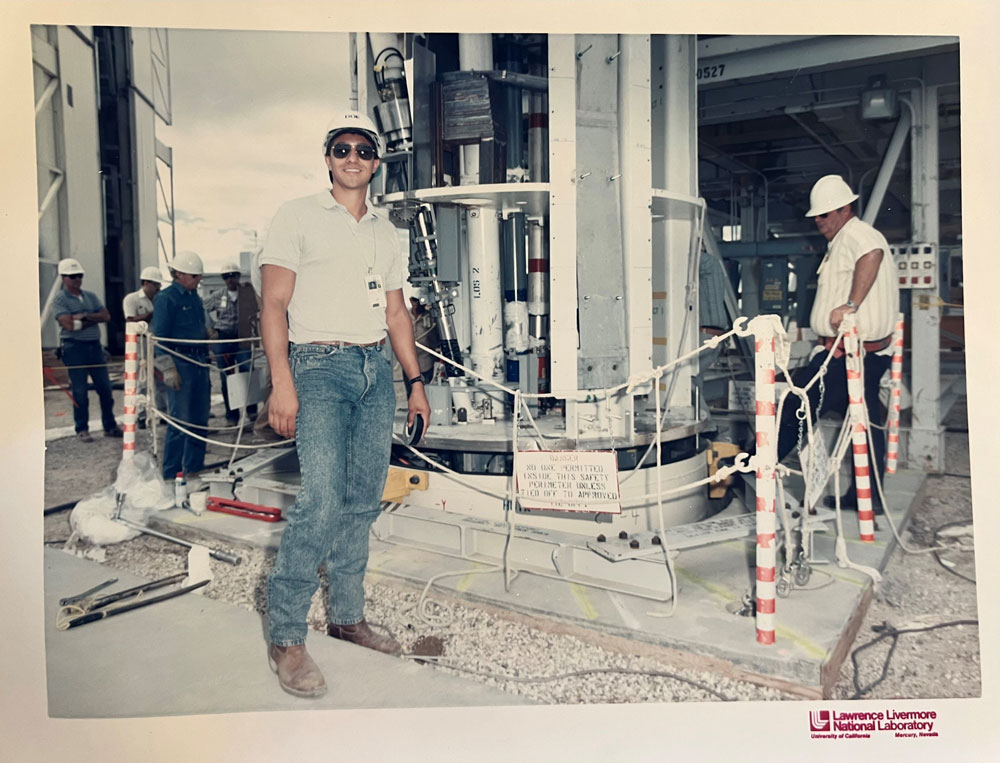

In 1986, Freddie Hidalgo joined a small, elite team of Sandia engineers and technicians responsible for arming and firing nuclear devices during underground tests at the Nevada Test Site. By the end of 1991, Freddie had worked on 12 weapons tests, each one requiring three to six months of intense on-site preparation and staging. This fall marks the 30th anniversary of the last nuclear weapons test, code-named Divider, conducted by the U.S. It was the last of 1,032 nuclear tests done over 47 years. To mark the anniversary, Lab News interviewed Freddie about his experience working in the nuclear test program.

Life at the test site

As a member of the arming and firing team, nicknamed A&Fers, Freddie was responsible for arming and firing “the device” and multiple fast-action closures designed by Sandia. His team supported Lawrence Livermore National Laboratory-led tests, 10 of which were shots where the device was lowered into vertical shafts located 800 to 2,200 feet underground. The other two tests were horizontal shots, conducted inside of tunnels at Area 12 of the test site.

While his team had fewer than 15 members, Freddie recalls the test site employing close to 10,000 people and running hundreds of buses daily to the test site, located in a Rhode Island-sized section of desert north of Las Vegas and south of Tonopah Test Range.

“For tunnel shots, we were basically miners at the time; it was like being one of the seven dwarfs,” Freddie said. “We’d ride these little miner trains, wearing our hard hats in preparation for working in dark and small spaces. Hopefully, you would never miss a morning, lunch or evening train to your alcove, otherwise it could be a long 25-minute walk through the tunnels.”

Prior to a vertical test, Freddie’s team prepared the arming and firing pedestal, which was about 6 feet wide and 3 feet tall. The team hardwired the different components that were used to set off the device. They also staged the Red Shack, a specially configured metal trailer that housed arming and firing power supplies and equipment needed to fire the device.

“Once the Red Shack was ready to go, we’d start doing daily dry runs to exercise the system without firing the device to make sure that everything was functioning as planned,” Freddie said. “On D minus one, the day before the test, we’d do our final dry run in a full power and full frequency configuration. If you had left a coffee pot plugged in or a light switch turned on in the Red Shack or any of the many diagnostic trailers, you didn’t touch it or turn it off until after the test. From an electrical standpoint, everything needed to be exactly the same for the morning of the test.”

Freddie also recalls performing K duty, the nickname for a technical and safety protocol required whenever a nuclear device was present.

“You always had to have two people there who were knowledgeable about every aspect of the operations,” he said. “When you were on K duty, you weren’t allowed to do any technical work. Instead, you had to watch those performing the work and make sure it was being done correctly and safely. K duty was an enormous responsibility, and there was never a dull moment.”

After the pre-arming operation was complete for a tunnel shot, workers would fill the ground zero alcove from floor to ceiling with sandbags. For one test, Freddie was on K duty and was the last person to exit the 12-by-12-foot alcove through a small opening near the ceiling. The tunnel workers had to carry him above their heads as he crawled out from the opening, like body surfing at a concert.

Permission to arm

At 2 a.m. on the morning of a test, the arming and firing team would wake up in their bunks adjacent to the control room. After a briefing, the team would drive for more than an hour to ground zero in a guarded convoy with security lights flashing. There, they would complete dozens of electrical checks and then play cards, eat popcorn and wait for a final call to be relayed from Las Vegas to the test director to the Red Shack through a red phone wired directly to the control room.

The call would give “permission to arm,” during which the team would remove the firing cables from a two-person-controlled, double-keyed lock box and proceed to connect them to the Zero Rack, a large relay chassis, and perform one last electrical verification before taking another long drive through the desert back to the control room. After daylight, usually by 8 a.m., the countdown would start. The team would remain in the control room to ensure that all items associated with the arming sequence occurred as planned and ultimately resulted with the fire signal being sent to detonate the device.

About 20 seconds after detonation, the control room located 10 to 40 miles away from ground zero would start to shake, similar to an earthquake. For some tests, the shock wave could be felt in Las Vegas. At ground zero, the shock wave would immediately hit the trailer park that housed the diagnostic trailers, the timing station and Red Shack, throwing all of them up in the air. The trailers would land on specially configured stacks of foam blocks that would crush and flatten as they absorbed the impact.

Executing the mission, then and now

The last test Freddie worked on, code-named Bristol, was in November of 1991. With the moratorium on nuclear weapons testing on the horizon, Freddie moved to Albuquerque to work with NNSA’s Office of Safeguards and Transportation. He started his new role as an engineer for the OST Relay Stations, then supported nuclear weapon security programs as a Sandia project lead.

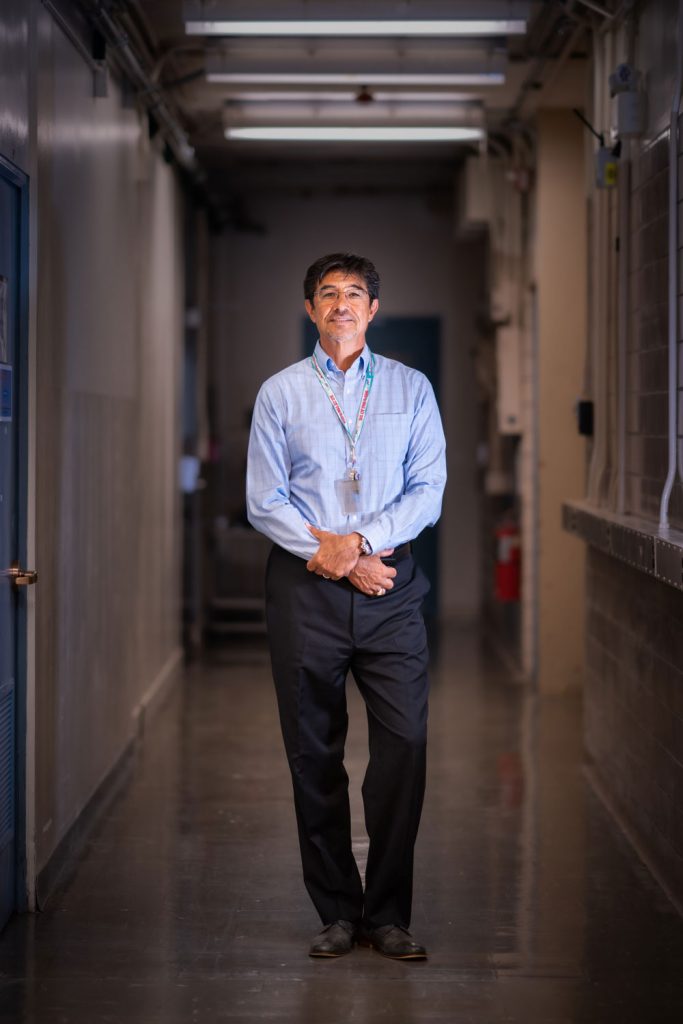

Later, he worked in the private sector for 10 years before returning to Sandia to support B61-12. Today, he manages a product realization team that designs weapon interconnect components for the W80-4. While a lot has changed in 35 years, he said that the call to support Sandia’s mission remains strong.

“Back then we dreamed big, and I think today Sandians are still dreaming big. A lot has changed, but the heart of the people, their drive to execute the mission, is one stitch that holds us all together,” he said. “For me, it’s knowing the importance of the nation’s nuclear deterrent in keeping the world and our country safe that motivates me to get up every morning.”