Sandia engineers Bradley Jared and Nick Leathe exposed more than a dozen freshman students from a 3D printing class at Stanford University to some of Sandia’s additive-manufacturing capabilities in a May 20 online class.

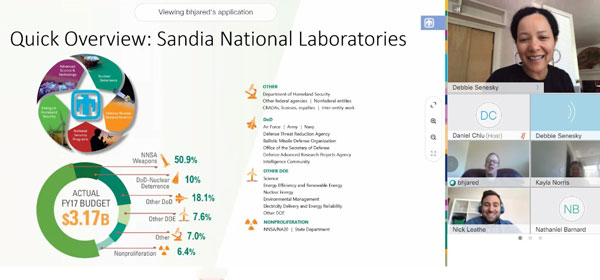

Bradley kicked off the remote discussion via WebEx by introducing Sandia’s wide-ranging portfolio and dedication to advancing and protecting national security. He went on to explain Sandia’s focus on risk reduction and innovation while describing the complexities and details involved with engineering materials that are both durable and functional and can range from the development of batteries to rockets.

Finally, he described the development of multi-material integration as “print everything inside the box, not just the box.”

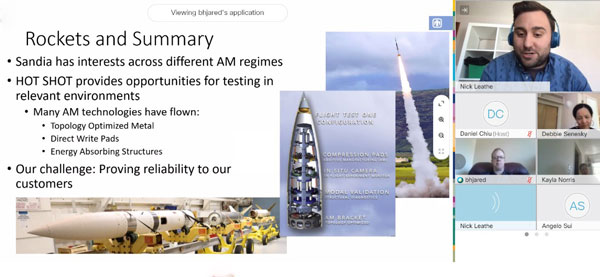

Both Bradley and Nick discussed their roles at Sandia using additive manufacturing to engineer products, specifically in the aerospace field.

Nick described using 3D printing technologies to expand opportunities to develop prototypes that can be tested on rockets at Sandia’s Kauai Test Facility in Hawaii. He also described Sandia’s goal as working to prove reliability and functionality for customers while innovating engineering designs for the future of national security and engineering.

Learning opportunities continue

“During this virtual world that we’ve immersed into, it’s as important as ever for Sandia’s Community Relations team to create and promote educational outreach opportunities,” said Stanford Associate Professor Debbie Senesky. “The goal of Sandia’s presentation was to expose students to real-world applications of additive manufacturing, as well as the career paths of Sandia employees.”

Senesky, who was a big part of STEM Day for Girls at Sandia’s California campus in March, said she was pleasantly surprised to learn about the range of fundamental science approaches that Sandia uses to bring additive manufacturing to maturity. She also shared that her students have adapted very well to the online lecture/class format. For example, they have used an additive-manufacturing service (you3dit.com) to give students “hands-on” experience with designing, building and testing 3D-printed parts. They made 3D-printed gliders for their midterm and final projects.

Bradley and Nick answered questions from the students and encouraged them to think about Sandia for future internships and career opportunities.

Senesky closed by thanking Sandia for the opportunity to learn more about the Labs’ efforts in this area and for her students to have the opportunity to engage with Sandia engineers.