Innovations developed at Sandia bring home four national awards

Technology that helps men test their fertility is among Sandia’s four national award winners honored by the Federal Laboratory Consortium for work to develop and commercialize innovative technologies.

“These awards are highly competitive,” said Jackie Kerby Moore, Sandia’s manager of technology and economic development and the Labs’ FLC representative. “This year our honorees include three start-up companies who are successfully deploying Sandia technologies, creating jobs and generating far-reaching impacts.”

The FLC is a network of more than 300 federal laboratories, agencies and research centers. The national FLC awards are some of the most prestigious honors for federal laboratories and industry partners that demonstrate outstanding technology transfer achievements.

The tech transfer success that led to the Trak Male Fertility Testing System received an Impact Award, a new category this year that honors efforts and successes that have made a lasting impact for people or the marketplace, ranging from a local to global scale.

Former Sandia inventors Greg Sommer and Ulrich Schaff developed Trak, which is based on the Labs’ SpinDx portable lab-on-a-disk diagnostic technology, originally developed to detect biological and chemical threats.

When Sommer realized there could be multiple commercial applications for the SpinDx technology, he left Sandia through the Entrepreneurial Separation to Transfer Technology program and started Sandstone, a company that specializes in producing medical products and research tools to improve healthcare. Schaff later left Sandia to join the company.

Trak enables men to measure, track and try to improve their sperm count at home to boost their chances for conception.

“Trak is a private, discreet and complete home testing system that is as accurate as the lab,” said Sommer. “It is not only a testing device, but an entire system to help men make changes to their health and lifestyle to improve their reproductive health.”

Sandstone continues to refine and develop the technology, which they now call CentriFluidics. The company has applied its technology to additional diagnostic areas, including infectious disease.

The other Sandia innovations that earned national FLC awards this year include:

- Efforts made by business development specialist Jason Martinez to increase partnerships and research between the Labs and nonfederal entities.

- Research that enabled a Sandia scientist to start a company using hydrogen fuel cells to power vessels.

- Creativity in technology transfer that helped a company obtain funding to build a reactor to produce medical isotopes for the world.

Connecting with universities, businesses

Jason received an Outstanding Technology Transfer Professional Award for his work to promote and set records for Sandia’s Cooperative Research and Development Agreements, the only binding mechanism that allows DOE labs to collaborate with nonfederal entities, including universities and businesses.

Jason developed and implemented the first CRADA strategy for Sandia. Since its inception in 2015, the strategy has helped the Labs’ CRADA portfolio grow each year, and the contract value has surpassed that of previous years. The strategy generated growth through education and outreach; builds, manages and leverages relationships across organizational boundaries; and promotes CRADAs as mechanisms to harness the innovation of industry and affect laboratory capabilities.

“Providing exceptional service in the national interest from a technology transfer perspective requires a proactive, hands-on approach,” Jason said. “Expanding collaborative opportunities with a risk-conscious strategy supports the mission of Sandia and the Department of Energy by addressing germane and exigent national security concerns while benefiting the academic and business community through the transfer of knowledge and capabilities.”

Other results of the strategy have been a reduction in CRADA processing time from six to two weeks and vastly improved customer satisfaction, as measured through surveys.

Hydrogen fuel cell vessels

Sandia received an Excellence in Technology Transfer Award for evaluating and demonstrating the feasibility of using hydrogen fuel cells in maritime applications.

Fuel cells turn hydrogen fuel into electricity using no moving parts while producing no exhaust other than clean water. But until an inquiry from a San Francisco ferry boat operator in 2014, scientists in the U.S., including those at Sandia, had not yet studied how to apply hydrogen fuel cells to ships.

Sandia physical chemist Lennie Klebanoff and former Labs scientist Joe Pratt had previously researched how hydrogen fuel cells could be used for vehicles, construction lights, power generators and power on board commercial airplanes. When the inquiry came in to apply the technology to ships, the researchers applied their knowledge on hydrogen fuel cells to determine the feasibility of using them on vessels.

After Lennie and Pratt developed a method to use hydrogen fuel cell technology for maritime applications, Pratt left Sandia through the Entrepreneurial Separation to Transfer Technology program, launching Golden Gate Zero Emission Marine.

Pratt’s zero-emission marine company is a full-service provider of hydrogen fuel cell marine power systems that are clean and quiet and comply with all current and projected environmental regulations.

With a technically solid foundation based on the Sandia studies, the company received funding to construct and deploy the first hydrogen fuel cell vessel in the western hemisphere and the first commercial fuel cell ferry in the world. The vessel, named the Water-Go-Round, is scheduled for christening later this year.

Sandia now has a CRADA with the company to independently measure the performance of the fuel cells on the Water-Go-Round.

Radioisotopes for medical use

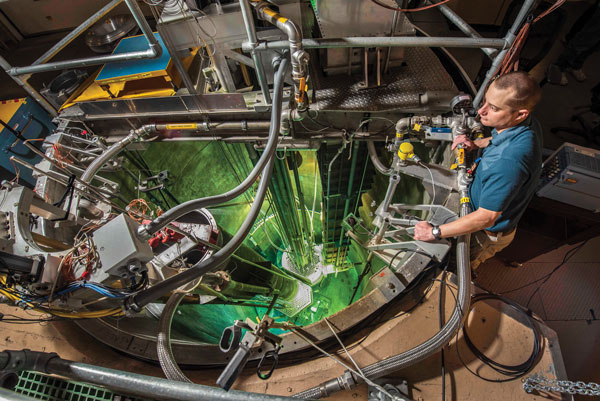

The FLC honored Sandia with an Excellence in Technology Transfer Award for developing a way to make medical isotopes with a small, low-power reactor using low enriched uranium and transferring the license to Eden Radioisotopes. Following some changes to the license, the company received funding in 2019 to build a reactor in southern New Mexico to make the isotopes. This will help with the worldwide shortage of isotopes that are critical to the medical field.

Medical isotopes are used around the globe in imaging procedures that diagnose heart disease, cancer and other life-threatening conditions. Building the reactor created a new and robust capacity to replace a limited number of aging reactors in the world that produce molybdenum-99, or moly-99. Moly-99 decays to technetium-99m, a short-lived isotope that can be used to make individual patient doses, said Eden Chief Operations Officer Chris Wagner. When any of these aging reactors experience unplanned outages, it can quickly cause patient dose shortages and price spikes.

Medical isotopes are used for 40 million nuclear medicine diagnostic procedures worldwide each year, Wagner said. In the U.S. alone, these isotopes are used for more than 40,000 medical diagnostic and therapeutic procedures each day.

“The new Eden reactor has the ability to assure a reliable future supply of medical isotopes for millions of patients worldwide,” Wagner said. “Making a difference in the lives of heart and cancer patients by helping to obtain diagnostic information is what motivates the team at Eden.”