Eventual savings expected to reach 16 million gallons annually for Sandia supercomputer center

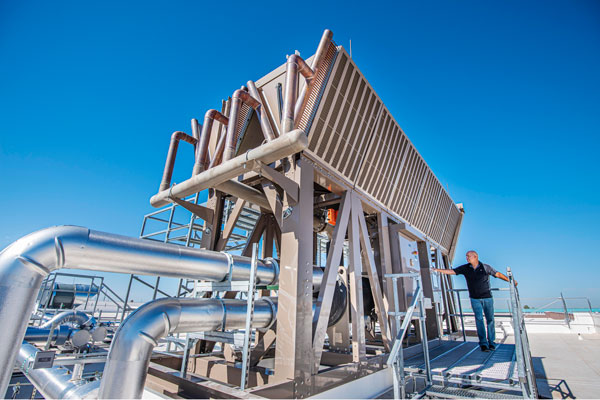

A cooling unit installed on the roof of Sandia’s supercomputer center saved 554,000 gallons of water during its first six months of operation last year, said David J. Martinez, engineering project lead for Sandia’s Infrastructure Computing Services.

The dramatic decrease in water use, important for a water-starved state, could be the model for cities and other large users employing a significant amount of water to cool the thirsty supercomputer clusters springing up like mushrooms around the country, he said.

The unit, called a thermosyphon cooler, also saved more than 195,000 kilowatt hours of electricity during the same period by making it unnecessary to pump thousands of gallons of water around the clock through energy-intensive mechanical chillers.

“We’re testing out the system because that’s what national labs do: we’re among the first to try things,” Dave said. “Others may come along when they see our success.”

Reusable refrigerant

Every bit of electricity used to run the servers of increasingly large supercomputers turns into heat. Removing that thermal energy is expensive, either in the financial cost of powering mechanical cooling units or in the amount of water needed to replace that portion deliberately evaporated to cool the remaining water. Neither choice is a plus for the environment.

The thermosyphon cooling unit intercedes passively. Its refrigerant rests in a shell that surrounds an outgoing pipe like a glove on a hand, absorbing heat until the liquid evaporates into a gas, like boiling water becomes steam. The gas rises in vertical pipes until it reaches the upper limits of the device. There, it gives up its acquired heat to the atmosphere, coalesces back into liquid and sinks down, ready to cool again.

The cycle needs minimal maintenance. It works as long as the atmospheric temperature is less than that of the refrigerant; otherwise, the heat transfer goes the wrong way, from the atmosphere into the coolant.

In New Mexico, the system works for three seasons, but in summer, only at night. On hot summer days, the thermosyphon shuts down and water must be pumped to a mechanical chiller and then to a cooling tower, which evaporates water like sweat from a body into the atmosphere.

Because minerals don’t evaporate, the remaining water, recycled, has a higher concentration of contaminants, which means it frequently must be changed out, like oil is periodically changed on a vehicle before it fouls the cooling pipes. The evaporated and discarded water must be replaced. Those problems are almost eliminated with the new system.

Saving more than money

The solution is not cheap. Thermosyphons cost $200,000 each from their manufacturer, Johnson Controls. Sandia has installed one, bought two more, and may buy a fourth. For four units, annual cooling costs would drop, according to Dave’s estimates, from $181,000 to $116,000, which means a roughly 10-year payback in current dollars.

The real saving would come in water: “When the data center reaches full design load, each thermosyphon unit will be capable of saving over 4.2 million gallons of water per year,” he said.

Dave won a DOE energy award last year for working on a far smaller version of the same type of system with the National Renewable Energy Lab in Golden, Colorado.