Does it seem like rooftop solar panels are popping up everywhere in New Mexico? Have you been to Europe recently and seen massive solar cell arrays beside many roads? Solar cell industry statistics confirm these observations.

Since 2004, the rate at which solar cell power is installed has doubled every 22 months and is now in excess of 0.1 terawatts per year.

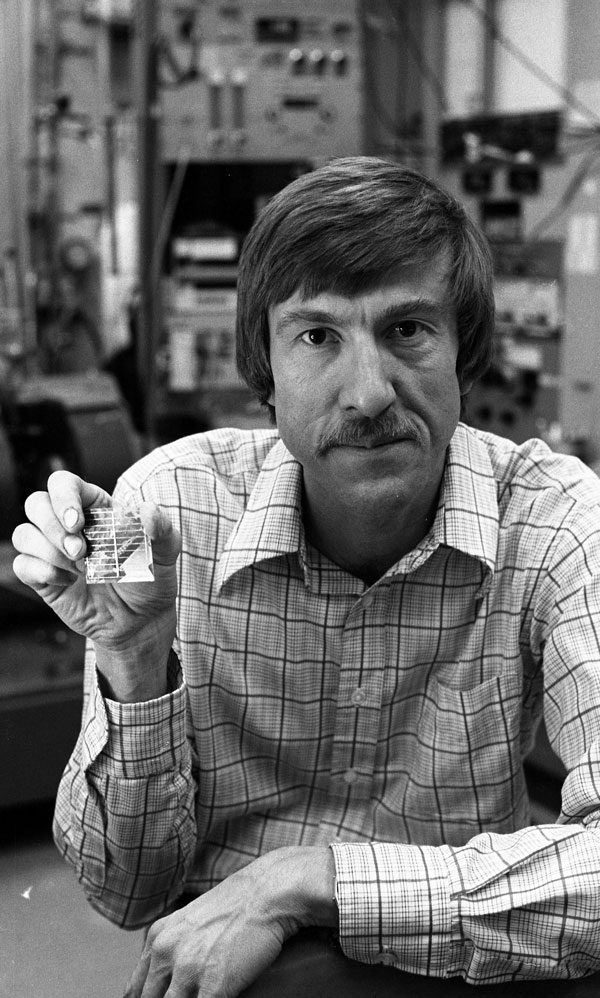

Research driving some of this expansion began right here at Sandia more than 40 years ago. When the Arab oil embargo produced major gasoline shortages and price increases, the federal government responded by funding research on renewable energy sources. Sandia began programs on wind energy, geothermal power, solar thermal energy and photovoltaic (solar) cells.

While most of Sandia’s solar cell funding aimed at processing expensive single crystal silicon cells for concentrator use, a second initiative involved fundamental research addressing the issues involved in producing cheap flat-panel cells. The program initially focused on developing thin-film silicon solar cells, but it later included work on other types of silicon cell structures.

Single-crystal silicon wafers, where all the atoms are perfectly aligned in a single orientation, were far too expensive to meet program goals,

so inexpensive growth techniques that produced silicon layers consisting of many randomly oriented crystals were investigated.

However, it was known then that the regions where these misoriented crystals came into contact, grain boundaries, could degrade solar cell performance. The electronic structure of these regions was disturbed by the atomic misalignment and, possibly, by the tendency of these boundaries to attract impurities. Little was known then about the relative importance of either of these effects.

The program to understand these grain boundary regions and their effects on solar cells involved cooperation with other national laboratories, high-tech companies, numerous Sandia staff members and a visiting faculty member from the University of Rochester. These efforts spanned seven years and enjoyed continuous funding from both Sandia and, later, the National Renewable Energy Laboratory, then called the Solar Energy Research Institute.

In addition, scientists from Oak Ridge National Laboratory helped initiate the program by supplying special polycrystalline silicon material. With these samples in hand, new electrical techniques were devised to measure the electronic properties of the grain boundary regions, and several theoretical studies were completed that allowed this new data to be used to deduce the actual density of the “bad” electronic states in these regions.

These initial investigations allowed Sandia researchers to quantitatively characterize grain boundary properties in routine fashion, and it became clear that the next step should be to thermally or chemically modify these boundaries. Based on emerging information from studies of amorphous semiconductors, equipment was constructed to expose the silicon grain boundary samples to atomic species of fluorine, hydrogen and other gases, which involved creating low-pressure plasmas of these gases at elevated temperatures.

The hope was that these species would diffuse into the silicon and tie up, or passivate, the “missing” chemical bonds that were created by the structural disorder at the grain boundaries. To monitor the effects of these treatments, researchers observed the resistance of these structures when electrical currents were forced across them. While little change was seen in boundary resistance for most of the gases that were tried, remarkable changes were seen when hydrogen was used. In some cases, reductions of boundary resistance by factors of 100 or more were seen, and it became clear that these chemical treatments might hold promise for improving solar cell performance.

From this point on, the focus of the program changed to observing the effects of these passivation treatments on real solar cells. Prototype polycrystalline silicon cells were obtained from Honeywell Corp. and Mobil Solar Energy, and other Sandia researchers with expertise in ion beams were brought into the program. Their equipment produced directed beams of hydrogen ions that had specific energies and fluxes, so modeling of the hydrogen passivation process could be made more quantitative.

Using this approach, it became clear that short exposures of typical polysilicon cells to hydrogen ion beams could improve typical efficiencies by 20-30 percent. More importantly, the statistical spread in cell outputs could be significantly narrowed, and the resulting improvements were extremely impervious to repeated illumination and thermal cycling.

While the results of this research attracted considerable attention, the full economic impact of this work would only emerge more than 30 years down the road. The growth and slicing of silicon wafers and ribbons continued to be expensive and time consuming, and the costs associated with photovoltaics were not competitive with conventional power sources.

But things were beginning to change. In the early 1990s scientists at Mobil Solar found a way to introduce hydrogen by heating a hydrogen-rich layer applied to cells to reduce reflection. In the early 2000s, the cost of growing and slicing polycrystalline silicon ingots began to drop sharply, and production of cells in countries with cheap labor accelerated a reduction in reduced cell costs. From 2004 to the present, the total investment in polycrystalline silicon solar cells is more than $300 billion. This truly is a remarkable growth industry with no end in sight, and the passivation process discovered at Sandia is still an important key to cell efficiency.

Are there lessons to be learned from this story? I think so. Federal investments in renewable energy can have big impacts that can’t be predicted. It’s important to take a long-term approach if we wish to see future payoffs similar to these Sandia-led successes in photovoltaics.

Some of the research described appeared in the paper, Passivation of grain boundaries in polycrystalline silicon, by C.H. Seager and D.S. Ginley of Sandia. Appl. Phys. Lett. 34 , 337 (1979); doi: 10.1063/1.90779.