Real-time structural health monitoring to detect bridge cracks

Along with flying cars and instantaneous teleportation, smart bridges, roads and subway lines that can send out warnings when they’re damaged are staples of futuristic transportation systems in science fiction.

Sandia National Laboratories has worked with Structural Monitoring Systems PLC, a U.K.-based manufacturer of structural health monitoring sensors, for over 15 years to turn this science fiction into science fact. They outfitted a U.S. bridge with a network of eight real-time sensors able to alert maintenance engineers when they detect a crack or when a crack reaches a length that requires repair.

Next week, Sandia Senior Scientist Dennis Roach will present his team’s work at the ninth International Conference on Bridge Maintenance, Safety and Management. His presentation will include data on the trial bridge, a general assessment of the sensors used and his proposal for how to make structural health monitoring more routine in transportation infrastructure.

The goal of structural health monitoring is to increase supervision of critical areas, extend the lifetime of structures and ultimately reduce operating costs and improve safety. To assess the condition of a bridge or other transportation infrastructure, researchers mount sensors on the structure and carefully analyze the data.

In 2016, more than 54,000 bridges in the U.S. were classified as “structurally deficient” by the Federal Highway Administration’s National Bridge Inventory. This means about 9 percent of U.S. bridges need regular monitoring.

“Areas that are difficult to access or things that are remotely located like bridges, pipelines and other critical structures present significant challenges to properly monitoring the health of the structure or equipment,” Dennis said. “A network of structural health monitoring sensors could be a solution, or at least help ensure the necessary vigilance over these components.”

‘Fool-proof’ vacuum monitoring sensors

The structural health monitoring system for the trial bridge consists of eight Comparative Vacuum Monitoring sensors, a vacuum pump to form the vacuum, a control system to turn on the vacuum pump and periodically check the sensors and a wireless transmitting device to autonomously call or text the maintenance engineers if a sensor detects a crack. The whole system is powered by a lithium ion battery, which is recharged by a solar panel.

The team placed sensors along several welds on a truss 100 feet above the deck, or flat road surface, on a suspension bridge.

Recently, Sandia and Structural Monitoring Systems, which has a significant presence in North America, worked with Delta Air Lines Inc. and the Federal Aviation Administration to get the Comparative Vacuum Monitoring sensors industry-certified for crack detection on commercial aircraft. Roach’s work with structural health monitoring for commercial aircraft began in 2001 through the FAA’s Airworthiness Assurance Center, which Sandia has operated for the FAA since 1990.

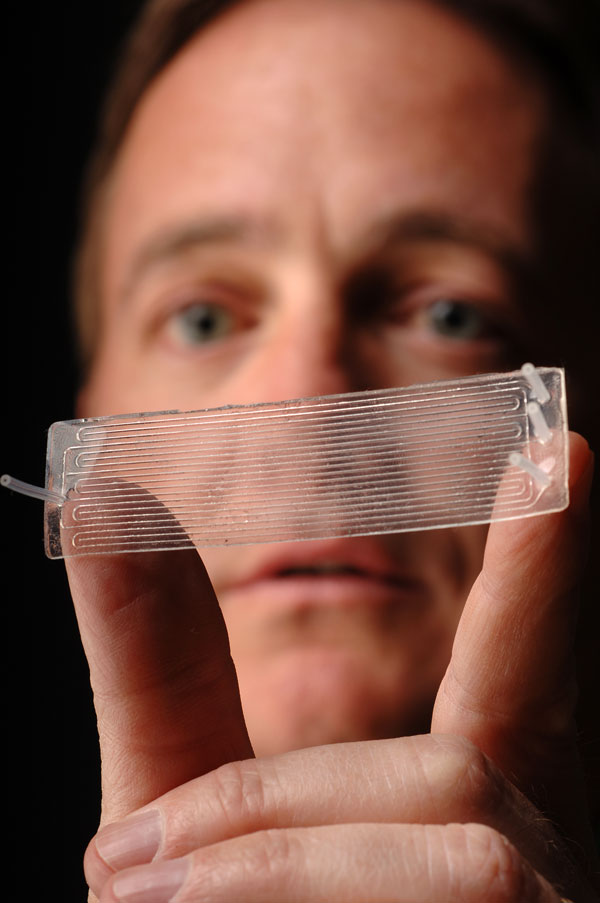

The Comparative Vacuum Monitoring sensors produced by Structural Monitoring Systems are made of thin, flexible Teflon and have rows of little channels, called galleries. They can be stuck onto critical joints or welds or placed near other places cracks are likely to form.

When the metal is whole, the pump can remove all of the air out of the galleries and form a vacuum. When a tiny crack forms in the metal underneath the sensor, it can no longer form a vacuum, like a vacuum cleaner stops working when the hose leaks. These sensors can detect cracks smaller than the thickness of a dime.

The sensors can be produced in many different shapes, depending on the region that needs to be monitored, such as across a long weld or around a series of bolts. They can even be placed in a series in front of a tiny crack, to see whether it grows and if so, how fast. Each sensor has numerous control galleries and monitoring hardware so it can tell if there’s something wrong with the sensor or connecting tubes. Because of these control galleries, the sensors are practically fool-proof.

Henry Kroker, a Structural Monitoring Systems engineer who played a key role in the bridge monitoring project, said, “Comparative Vacuum Monitoring sensors provide an elegant ‘Green-Light, Red-Light’ method for constantly surveying critical components. In many years of trial and permanent use in the aviation and now

civil industries, theses sensors have not produced any false calls.”

Future of structural health monitoring

The team’s work on smart infrastructure began in 2005 through a Sandia-sponsored Laboratory Directed Research and Development project that used mounted sensors and wireless data transfer to continuously monitor a wide array of civil structures, everything from heavy mining equipment to railway systems and bridges. These sensors monitor the health of structures and mechanical devices by detecting the presence of corrosion and cracks and even the condition of critical moving parts.

Roach and his team also use piezoelectric sensors, fiber optics and printed eddy current sensors for structural health monitoring.

Printed eddy current sensors, a Sandia-patented technology, can be installed on curved surfaces and use changes in a magnetic field to detect cracks. On the other hand, a network of piezoelectric sensors can monitor a wide area instead of just a few patches. Each sensor takes turns sending a vibration through the underlying material that the other sensors receive. Cracks or other damage within the sensor network change the “pitch” of these vibrations. However, such pitch changes are more complex than the “yes” or “no” provided by comparative vacuum monitoring. Comparative Vacuum Monitoring is ready and certified for commercial use, while the other technologies are still in different stages of lab and field testing.

“In 15 years of testing Comparative Vacuum Monitoring sensors, they have achieved a tremendous track record for producing dependable structural health monitoring,” said Tom Rice, the Sandia mechanical test engineer in charge of testing various structural health monitoring systems. “Once they get incorporated into more systems, in areas of concern, it’s just going to make aircraft, trains and bridges safer as time goes on.”

Structural health monitoring is especially good for hard-to-reach or remote areas, but it’s not a panacea for all inspection needs, Dennis said.

“There’s still plenty of times when you want a human in there with a flashlight or other inspection equipment, reasoning it out.” With that caveat, he added “Structural health monitoring is only beginning to scratch the surface of the varied types of infrastructure it could be used for.”

Railcars and rail lines, ships, wind turbines, power plants, remote pipelines, storage tanks, vehicles, even buildings could benefit from real-time, remote structural health monitoring. “The civil infrastructure industry is becoming more aware of the benefits structural health monitoring can provide and is now interested in using them,” Dennis said.