Studying materials information through dynamic compression

Sandia post-doctoral appointee Joshua Townsend, casually dressed in a dark green pullover and light brown pants, sits on what is effectively an aluminum saddle between the split components of a gas gun’s backstop.

He’s absorbed in attaching wires to sensors embedded in a target about the diameter of a dinner plate. Once he’s done and moved out of the way, technicians will close the backstop so that the gun can fire a projectile into the plate.

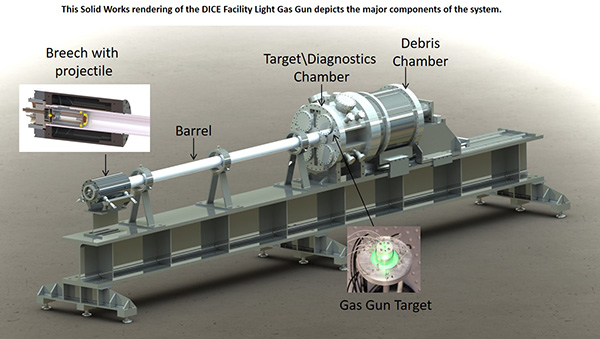

A gas gun’s projectile is not a lightweight matter. A railroad shock absorber is needed to neutralize the impact of each shot, which originates in a cannon bolted to the floor about nine feet away. Impelled not by ignition but by the sudden expansion of helium gas released into the barrel from a side pocket behind the projectile, it will scrabble forward like an NFL lineman to hit with the impact of more than 500 pounds per square inch. An exhaust valve downstream releases pressure before it builds high enough to be dangerous.

The guns of shock physics at Sandia have been used to explore everything from the properties of new materials to the 2003 Columbia shuttle disaster. Says Randy Hickman, test operations engineer at Sandia’s gas gun center, “The piece of foam that struck the shuttle’s heat tiles and caused the crash would not normally be considered [hard enough to be] an issue, but anything moving that fast can damage a vehicle. Similarly, we’ve studied debris shields for the space station and satellites, armor materials for the military, and even potential meteor impacts on earth and other planets. For anyone who needs an understanding of the mechanical properties of a material, we have the ability to probe it at various pressures and temperatures to obtain conditions of failure or uniformity.”

One problem for students interested in entering the field, however, is finding hands-on practice. Because of the complicated nature of shock physics, the science of dynamic compression — the way a material behaves when impacted — is taught at only a few top universities, and even there the subject matter is almost entirely theoretical.

“Hardware is hard to come by,” says Randy.

Theory + experiment = better science

But because the subject has so many applications, Sandia management believed that time spent providing students hands-on experience with real shock physics experiments could improve their modeling skills, and so Sandia provides a program to supplement theoretical university courses with projectiles and real shocks.

Says Josh, normally involved in high-energy-density physics theory, “I had never encountered [the field of] shock compression of materials before Sandia. Then, through the program, I got my hands on materials and realized it’s useful for me to know how the experiments are done. Then I can work more efficiently with experimentalists. I realize up front why they can’t just go out and measure something I would think, from calculations alone, could be easily done. So, we improve our combination of experiment and theory to do better science than could be done separately.”

Says Sandia shock physicist Seth Root, “To help our post-docs learn the technical aspects of shock physics, we designed experiments involving the complete assembly of a shock physics target. Post-docs assemble the target sample, attach optical fiber and electrical signal diagnostics, and make all the measurements. Then they learn how a target is installed in the gun, how the optical diagnostics work, and even participate in the post-experiment clean-up. Then, with data from the experiment, students determine characteristics of the target sample. Combining the theoretical class with our hands-on practice helps our post-docs transition faster and more confidently to the specialized work we do in dynamic compression.”

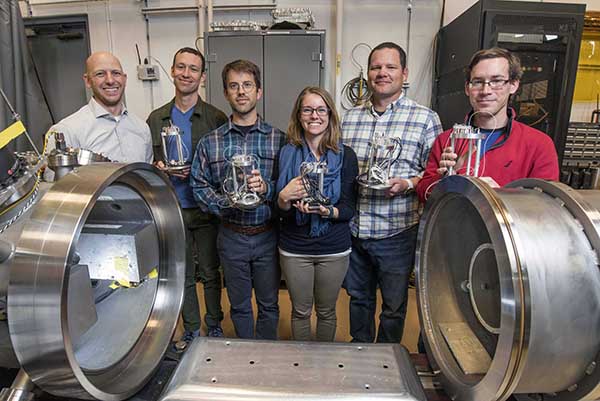

HANDS ON — Posing next to a gas gun open for servicing are, left to right, Sandia shock physicist Seth Root and postdocs Matthew Hudspeth, Joshua Townsend, Bethany Chidester, Jim Williams, and Ray Clay, who are holding the targets they created. (Photo by Randy Montoya)

The gun’s relatively inexpensive mechanism (when compared with the costs to do experiments on pulsed power machines, like Z, which achieve far higher pressures) means projectiles can be sent with a variety of velocities against targets. This creates a series of data points charting the behavior of a material under increasing pressure.

To realize this data accurately, pins of varying lengths are inserted in the target. The time difference between electrical signals from the longer ones, struck first by the incoming projectile, and signals from the shorter ones, struck last, allow researchers to calculate the projectile’s velocity. Meanwhile, a fiber optic probe measures the shock wave’s arrival time and profile.

Says Sandia research technologist Keith Hodge at the close of one test, “Manual dexterity is improved by work at constrained spaces the site provides.”

Joshua is one of four Sandia post-docs recently to get hands-on training in the program. They take theoretical coursework at the Institute for Shock Physics at Washington State University, which offers an introductory class that covers theoretical aspects of shock wave propagation, equation of state, and other topics important for dynamic compression.

“I think we post-docs all knew basic thermodynamics before going into the experiment,” says Joshua. “But we had no clue about how to produce a set of experimental measurements. In this respect, it is the hands-on experience that is novel and most important.”