Sandia researchers use Direct Numerical Simulations to enhance efficiency, reduce pollution in diesel engines

A “cool flame” may sound contradictory, but it’s an important element of diesel combustion — one that, once properly understood, could enable better engine designs with higher efficiency and fewer emissions.

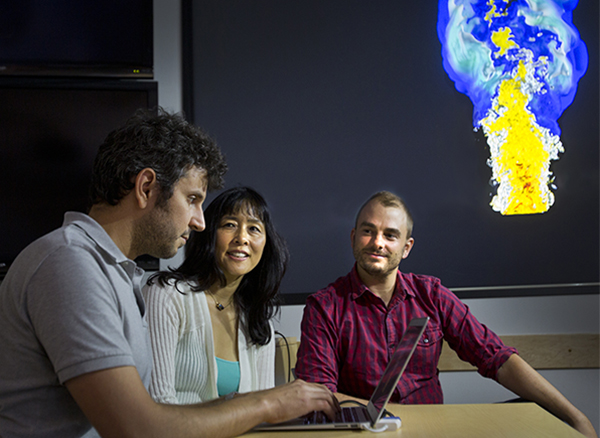

Sandia mechanical engineer Jackie Chen and colleagues Alex Krisman and Giulio Borghesi recently identified novel behavior of a key, temperature-dependent feature of the ignition process called a cool flame in the fuel dimethyl ether.

The adjective cool is relative: The cool flame burns at less than 1,150 Kelvin, about half the typical flame burning temperature of 2,200 Kelvin. While cool flames were first observed in the early 1800s, their properties and usefulness for diesel engine design have only recently been investigated.

“We’re trying to quantify the influence of cool flames in stratified turbulent jets during the ignition and flame stabilization processes. The insights gleaned will contribute to more efficient, cleaner burning engines,” says Jackie. “Our holy grail is to understand the physics of turbulent mixing coupled with high-pressure ignition chemistry to aid in developing predictive computational fluid dynamics models that can be used to optimize engine design.”

The team’s research has shown that during autoignition (the spontaneous ignition of injected fuel in a combustion engine), cool flames accelerate the formation of ignition kernels — tiny localized sites of high temperature that seed a fully burning flame — in fuel-lean regions. The work was performed at Sandia’s Combustion Research Facility using Direct Numerical Simulations (DNS), a powerful numerical experiment that resolves all turbulence scales, and was published in the Proceedings of the Combustion Institute with Alex as the lead author. The work was supported by DOE’s Office of Basic Energy Sciences.

“Our holy grail is to understand the physics of turbulent mixing coupled with high-pressure ignition chemistry . . .”

Giulio further extended the cool flame DNS study by performing a three-dimensional study on n-dodecane, a diesel surrogate fuel that has been the recent focus of Sandia’s Engine Combustion Network on spray combustion in diesels (the study that Alex authored with dimethyl ether, a simpler fuel, was in two dimensions). Giulio’s paper is pending publication. Taken together, both Alex’s and Giulio’s papers will form a comprehensive study of low-temperature chemistry in autoignitive flames at different stages of ignition.

Cool Flames Can Improve Engine Design

The details of starting an engine often are taken for granted. Unlike a gasoline engine, in which the fuel-air mixture is ignited with a spark plug, in a diesel engine the fuel must auto-ignite when it is injected into the hot, compressed air that is in the piston at the top of the piston stroke. As the fuel is injected into the engine cylinder, rapid mixing and combustion combine to burn the fuel and drive the engine. While this lasts mere fractions of a second, the conditions of the flame that start this powerful process are crucial for improving engine efficiency and minimizing pollution formation.

In a diesel engine, the fuel-air mixture is far from uniform, with some regions having high fuel concentrations and low temperatures and other regions having low fuel concentrations and high temperature. In other words, the in-cylinder condition is highly stratified. Alex and his coworkers discovered that stratification, combined with the complex ignition chemistry of the diesel-like fuel, create a fast-moving cool flame that controls the overall ignition behavior.

The rapid movement of the cool flame decreases the time needed for ignition, which is important when operating an engine with significant flue gas recirculation, a technique used to decrease soot and nitrogen oxide emissions and increase engine efficiency.

Studies performed on 27-petaflop supercomputer

“The cool flame triggers the hot ignition,” says Alex. “This causes the hot ignition timing and location to be markedly different to what would be otherwise expected. This discovery should improve our understanding of the very complex diesel ignition process.”

“Combustion processes are challenging to study because the fuel itself is quite complicated.”

The cool flame DNS studies were performed at the DOE’s Oak Ridge Leadership Computing Facility on Titan, a 27-petaflop supercomputer, using a DOE INCITE computational grant (Innovative and Novel Computational Impact on Theory and Experiment). Computations using some of the world’s largest supercomputers, such as Titan, are required to produce an accurate and detailed calculation of the autoignition process.

“Combustion processes are challenging to study because the fuel itself is quite complicated,” says Giulio. “Fuel oxidation chemistry consists of hundreds of species and thousands of chemical reactions. A realistic simulation of diesel combustion needs to capture this complex chemistry accurately in an overall model that includes turbulent mixing and heat transfer.”

As part of the DOE Exascale Computing Program, the team collaborates with outside institutions including NVIDIA, Lawrence Berkeley National Laboratory, National Renewable Energy Laboratory, Stanford University, Oak Ridge National Laboratory, Argonne National Laboratory, and Los Alamos National Laboratory to develop performance-portable algorithms to enhance the computing efficiency for DNS combustion studies.

Future Work

In the future, the team would like to investigate basic questions about the speed and structure of flames at diesel engine conditions and study the relationship between spray evaporation, ignition, mixing, and soot processes associated with multi-component fuels. These basic questions will contribute to studying the cool flame’s crucial role in engine energy production and exercise the valuable capabilities of DNS running on exascale supercomputers as a highly precise and detailed numerical simulation method.