Goodyear/Sandia partnership marks 25 years

Tires and national security might not seem to have a lot in common. But for 25 years, Goodyear and Sandia Labs have worked together and raised each other’s game.

In a partnership almost as old as technology transfer itself, Sandia Labs and Goodyear Tire & Rubber Company have worked together for 25 years to create better vehicle tires, more advanced computational mechanics, and keep Goodyear competitive in a tough business environment. “You might wonder how national defense systems and nuclear stockpile management relate to tire science,” says Mary Monson, senior manager of Technology Partnerships Dept. 1180. “But a tire is a complex system, and that’s something Sandia knows well. The partnership allows Sandia to enhance our software toolkits and improve our capabilities for mission applications while simultaneously addressing Goodyear’s proprietary challenges.”

Sandia and Goodyear signed a Cooperative Research and Development Agreement, or CRADA, in 1993, back when technology transfer from the national labs was in its nascent heyday. In 1980, the Stevenson-Wydler Technology Innovation Act was signed into law by President Jimmy Carter, becoming the first major US technology transfer legislation. It required federal laboratories to actively participate in and budget for technology transfer activities. Stevenson-Wydler was followed by the Federal Technology Act of 1986, the second major piece of legislation focused on tech transfer from federal government agencies to the private sector. It established the Federal Laboratory Consortium and let federal labs enter into CRADAs with private industry.

“Tech transfer was an exciting new opportunity for the labs.”

“Tech transfer was an exciting new opportunity for the labs,” Mary says. “The Department of Energy really embraced the tech transfer concept for federal agencies in the late 1980s, early 1990s. Part of the defense programs budget was put aside for US economic security for the nation as well as enhancing the unique capabilities of the labs through solving complex real-world problems. Labs made proposals and were awarded funding to collaborate with partners.”

Designing the ideal tire

Goodyear took note. It was the only remaining US tire manufacturer and needed to cut its R&D budget to stay competitive with companies like Bridgestone and Michelin. The company reached out to Sandia in the summer of 1992 and executives and scientists forged a relationship through back-and-forth visits to each other’s sites.

“They looked at our advanced computational mechanics software applications developed for nuclear weapons programs after the government halted underground testing and saw that they could be applied to tires. Instead of building and testing three to five prototypes before a tire was ready for manufacture, they could use our computer codes to develop one,” Mary says. “Time was dramatically reduced, by half or more.”

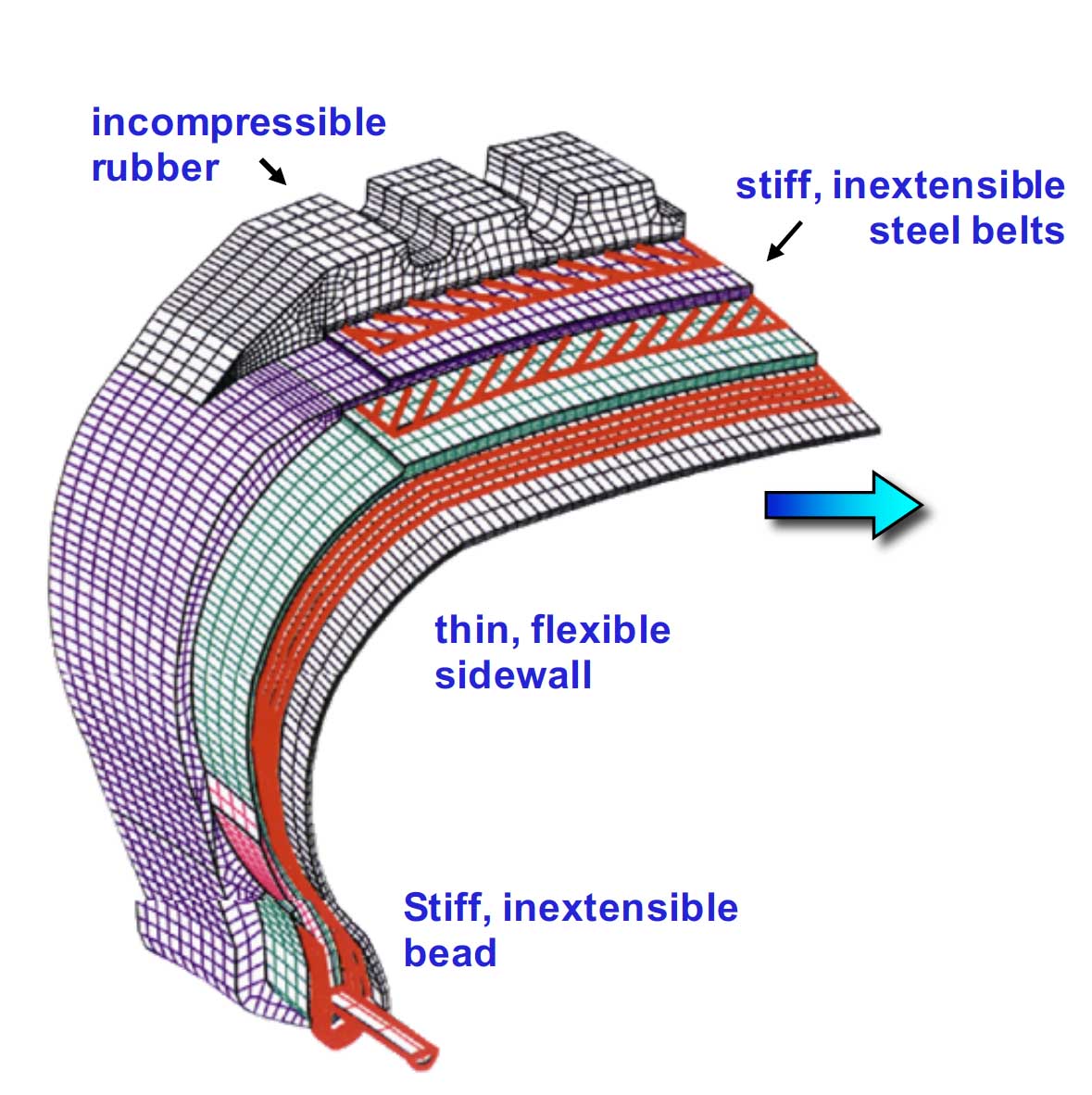

Sandia’s tools went to work on the many components of a tire system.

“It’s often surprising to people to learn just how complicated it is to model and simulate tire performance, considering millions of material combinations and permutations and blending structural mechanics, rigid body, and fluid dynamics under varying temperature, pressure, and wear conditions,” says Dale Moseley, Goodyear’s global project manager.

The collaboration produced the Assurance TripleTred, a unique all-weather tire with a three-part tread pattern. Goodyear wanted a visually distinctive tire that would generate buzz and demonstrate its best technology and quality, in 12 months. The Assurance line was launched in 2004, and in 2005 Sandia and Goodyear won a joint R&D 100 Award for the tires, particularly the TripleTred, which was brought from concept to market in less than a year. Goodyear says the tire could not have been produced without modeling and predictive testing tools developed with Sandia.

A wide range of lab technologies have played a role in the CRADA including advanced computational mechanics, computational simulation and verification, elastomeric materials, structural and tire dynamics, advanced manufacturing of rubber products, efficient characterization methods for structural dynamics, reliability tools for manufacturing processes, sensor systems, data science, human reliability, and engineered products.

Competitive advantage in a complex business

Today 100 percent of tire designs at Goodyear are modeled before molds are ordered. The company is in the top three of the world’s largest tire manufacturers and credits its work with Sandia for reducing new product development times, producing better tires and manufacturing methods, boosting efficiency, and lowering R&D costs, all contributing to a competitive advantage in a complex industry. “Our relationship with Sandia has been very beneficial in our competitive success in the global automotive industry, allowing us to begin submitting ‘virtual tires’ to automakers that can be incorporated into their vehicle models early in the development process as they tune the vehicle designs,” Moseley says.

“. . . the new capabilities they commission us to develop help us with simulations in our national security work.

The CRADA has been renewed repeatedly since 1993 and Goodyear continues to produce innovative products developed in collaboration with Sandia. “So many good things have come out of this enduring partnership,” Mary says. “It has worked both ways. We were able to apply our codes to a real-world problem, and improve our codes. And Goodyear was able to develop revolutionary products.”

Ted Blacker, manager of Simulation Modeling Sciences Dept. 1543, says the partnership has been successful because it is strategic. “We focus on strategic technical challenges where advanced technology from both sides can change the future,” he says. “Almost without fail, the new capabilities they commission us to develop, for example, to model rotating, twisting, and deforming tires, help us with simulations in our national security work.”

Much research done under the CRADA has been applied to Sandia’s science-based nuclear weapons stockpile stewardship mission. Finite-element analysis let Sandia look closely at re-entry vehicle vibration, and research on predicting materials lifetimes addressed design issues ranging from large-scale weapon component deformation to advanced earth penetrators.

The work with Goodyear led to a deeper appreciation at Sandia of the value of computer modeling in the early stages of development. “We showed that modeling and simulation made a difference in developing better products faster,” Ted says. “Our computational tools typically were used late in the process to understand why something broke and how to fix it. Now we use modeling more in the up-front stages, such as in the early design, to reduce testing.”

Mary says CRADAs are an important technology transfer tool. “They help us sustain and improve our capabilities because we’re applying our technology to a company’s pressing problems,” she says. “There’s an urgency. It’s not abstract.”

She says the Goodyear CRADA has allowed Sandia researchers to work with peers in industry and share best practices. “It really is collaborative,” she says. “Both teams bring a different way of looking at a problem. We have learned a lot through those interactions about how to approach problems differently.”