Sandia filed a patent last September for a unique materials approach in multilayered, ceramic-based, 3-D microelectronics circuits, such as those used in cell phones. The approach compensates for the effects of how something called the temperature coefficient of resonant frequency, which is one critical property of materials aimed at radio and microwave frequency applications, changes due to temperature fluctuations. The work was the subject of a two-year Early Career Laboratory Directed Research and Development (LDRD) project that wrapped up in March.

The LDRD team focused on developing fundamental understanding of why certain materials behave as they do. That knowledge could help manufacturers design and build better products.

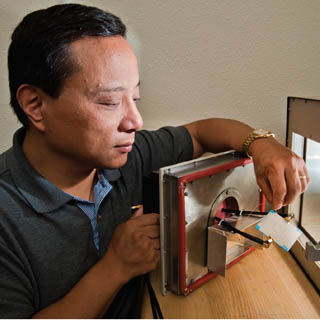

Steve, who spent 14 years with Motorola before joining the Labs in 2009, says Sandia was interested in the research for its own programs, but the work also has potential commercial applications. He says, however, no exact projects have been pinpointed.

“At this point we’re just demonstrating the technology,” he says. “We have to demonstrate that it’s practical, that we can design a device with it, that we can design it over and over again, and can design it reliably.”

Wasting potential bandwidth

The familiar cell phone illustrates how the development might be used.

The Federal Communications Commission allocates bandwidth to various uses — aviation, the military, cell phones, and so on. Each must operate within an assigned bandwidth which, like a pipeline, has finite capacity. But temperature variations in operating a cell phone cause the properties of the materials inside to change, and that causes a shift in resonant frequency at which a signal is sent or received.

Because of that shift, cell phones tend to operate in the middle of the bandwidth, avoiding the edges so as not to break the law by drifting outside the assigned frequency range. That necessary caution wastes potential bandwidth and sacrifices the rate at which data can move.

Under the LDRD, Steve worked on low temperature co-fired ceramic (LTCC), a multilayer 3-D packaging and interconnection technology that can integrate passive components. Most mainstream LTCC dielectrics now on the market have a temperature coefficient of resonant frequency in a range as wide as that between northern Alaska in the winter and southern Arizona in the summer. A dielectric is a material, such as glass, that does not conduct electricity but can sustain an electric field.

Steve’s research achieved a near-zero temperature coefficient by incorporating compensating materials into the multilayer LTCC structure.

A graph shows the differences. Resonant frequencies used in various LTCC base dielectrics today appear as slanted lines on the graph as temperatures change. Steve’s approach to an LTCC leaves the line essentially flat — indicating radio and microwave resonator frequency functions that remain stable as temperatures change.

“The critical kind of understanding about the science here is required to design the material right to achieve properties that complement each other,” Steve says.

He presented the results of the approach in a paper published in January in the Journal of Microelectronics and Electronic Packaging.

“We can actually make adjustments in the materials property to make sure the resonance frequency doesn’t drift,” Steve says.

And, he says, “if your materials property doesn’t drift with the temperature, you can fully utilize whatever the bandwidth is.”

Another advantage: Manufacturers could eliminate additional mechanical and electrical circuits now built into a device to compensate for temperature variations, he says. That would reduce costs.

One basic challenge of the project was choosing different materials that don’t fall apart when co-fired together, Steve says. Glass ceramic materials used are both fragile and rigid, but they’re also very solid with minimal porosity. Researchers experimented with different materials, changing a parameter, adjusting the composition, and seeing what worked compatibly.

“It’s in a sense like cooking, you mix all these things together — it’s cooking. You have these ingredients, certain things you do in certain ways, just making sure it works together. Even the equipment is very similar; we have furnaces, ovens, mixers. . . . Each step is very much like making bread or something,” he says.

Steve had to consider both physical and chemical compatibility. Physical compatibility means that as materials shrink when they’re fired, they shrink in the same way so they don’t warp or buckle. Chemical compatibility means each material retains its unique properties rather than diffusing into the whole.

Looked at variables to boost performance

The LDRD created a new set of materials to solve the problem of resonant frequency drift but also developed “more of an understanding of why this works this way,” Steve says. “Why select material A and not B, what’s the rationale? Once you have A in place, what’s the behavior when you make a formulation change, a composition change, do little things?”

Researchers looked at variables to boost performance. For example, the functional material within the composite carries the electrical signal, and researchers experimented with placing that material in different areas within the composite until they came up with what worked best and understood why.

“That’s really important, the why,” Steve says.

The team also constructed a computational model to analyze what happens when materials with different properties are placed together, and what happens if you change their order in the stacked layers or the dimensions of one material versus another.

“We study all these different facets, the placement of materials, the thickness, to try to hit the sweet spot of the commercial process,” he says. That’s where computer modeling helps. “Modeling can calculate all these things,” Steve says. “Modeling’s important. You cannot do exhaustive experiments. Modeling can change whatever you want, once you have the basic experiment.”

Manufacturing can be done as a simple screen printing process, a low-cost, standard commercial process much like printing an image on a T-shirt. Steve says the idea was to avoid special requirements that would make the process more expensive or difficult.

“That’s kind of the approach you try to take, make it simple to use with solid understanding of the fundamentals of materials science,” he says.