The initial phase of Sandia’s Scaled Wind Farm Technology facility (SWIFT), currently being constructed in partnership with Texas Tech University in Lubbock, will be a little bigger than originally planned. Leading wind turbine manufacturer Vestas will add its own 300-kilowatt, V27 research turbine to the two Sandia V27 research turbines.

Overstating water’s compressibility

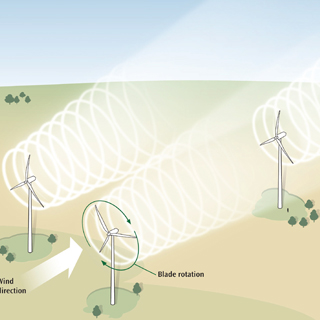

The Labs worked with Vestas to develop the new three-turbine site plan, uniquely tailored to study turbine-to-turbine interactions. Sandia and Vestas will conduct collaborative research with all three turbines, although each turbine can also be used separately with minimal interaction. “The Lubbock site benefits from high wind resource and low turbulence, which is ideal for research,” says Jon White (6121), project manager and researcher in Sandia’s Wind Energy Technologies group. “Wind at the site comes predominately from the south, making it easy to set up the turbine array for research on turbine-to-turbine interactions.” Vestas, the world’s leading supplier of wind turbines, partnered with Sandia and added its turbine to “create a technology accelerator that allows Vestas to bring innovations to market rapidly and cost-effectively,” says Anurag Gupta, director of rotor systems at Vestas Technology R&D in Houston. “The SWIFT concept reflects a shared emphasis among the partners on lowering the cost of wind energy by maximizing the output of a wind power plant rather than a single turbine,” Gupta says. The site will use V27 turbines, which are smaller than full, industrial-sized turbines. “The V27 turbines are the smallest turbines that retain significant characteristics to the study of larger-scale machines,” says Jon. “Having smaller turbines makes them easier to reconfigure, repair, and maintain. The cost differences mean researchers can do earlier-stage, higher-risk research at SWIFT and turn tests around much more quickly, allowing them to pursue a more robust annual research agenda.” Creating a new facility from the ground up also allows detailed characterization of the site and the turbine components before installation and testing. This gives researchers higher confidence in the accuracy of the wind turbine models they create based on research at the site. Studies at the site will investigate turbine-to-turbine interactions and innovative rotor technologies. Other areas for investigation include aero-acoustics and structural health monitoring of turbines using embedded sensor systems. Researchers will also continue work on Sandia’s structural mechanical adaptive rotor technology (SMART) program. “Most wind turbine rotors today are passive structures. Sandia’s SMART rotors have active surfaces similar to airplane wings, with actuators that change their shape, allowing for greater control and flexibility,” Jon says. The site eventually might expand to include nine or more wind turbines, which would allow researchers to further examine how individual turbines and entire wind farms can become better “citizens of the grid” and how to be more productive and collaborative .Jon says the team hopes to have the SWIFT facility operational by October. A flexible memorandum of understanding (MOU), signed by all four partners – Sandia, Vestas, Texas Tech University Wind Science and Engineering (WISE) Center at Reese Technology Center, and Group NIRE, a renewable energy development company – allows use of the site for collaborative and proprietary research, depending on research needs. DOE’s Wind and Water Power Program is funding Sandia’s work. Vestas has research and development offices in Texas, Massachusetts, and Colorado that work with the company’s technology centers in Asia and Europe to improve existing wind turbines and develop the wind power systems of the future. Since 1979, Vestas has supplied more than 46,000 wind turbines in 69 countries and employs more than 3,000 people in the United States in technology research, manufacturing, sales, and service