Sandia performs research on systems engineering processes and postclosure safety assessment methods to plan, develop, implement, and evaluate deep geologic disposal facilities for spent nuclear fuel (SNF) and high-level radioactive waste (HLW). Geologic disposal options for nuclear waste include mined repository concepts in salt, argillite, and crystalline rock and borehole disposal. Sandia conducts experimental studies, develops process models, and performs quantitative and qualitative analyses to further the scientific basis to safely dispose of nuclear waste. Our goals are to provide world-class leadership in deep geologic disposal research and development and to apply this expertise to integrate with pre-closure engineering, design, and safety analyses to support the development of a sound technical basis for multiple viable geologic disposal options in the United States.

Areas of Geologic Disposal Research and Development

The Sandia-developed Geologic Disposal Safety Assessment (GDSA) Framework is an open-source software toolkit for probabilistic safety assessment of deep geologic disposal options, including mined repositories and borehole disposal. The simulation engine for this modeling and analysis framework is PFLOTRAN, a massively parallel, multiphase flow and reactive transport simulator. Sandia’s PFLOTRAN software development team maintains and enhances the modeling capabilities necessary to simulate radionuclide transport in the subsurface and the thermal, hydrologic, mechanical, and chemical evolution of deep geologic disposal facilities. The open-source development environment has promoted worldwide use.

GDSA Framework’s state-of-the-art simulation and analysis capabilities for post-closure safety assessment have been demonstrated on generic deep geologic repository concepts in crystalline, argillite, and salt host rocks, as well as on generic deep borehole disposal concepts.

Sandia performs research and development (R&D) supporting the development of the technical bases for permanent disposal of SNF and HLW in mined geologic repositories. Sandia leads multiple DOE laboratories in this R&D, which includes computational and experimental studies examining the feasibility of various disposal concepts. Current mined disposal concepts include:

- Argillite Disposal Research and Development

- Sandia leads R&D to advance the understanding of long-term disposal of SNF and HLW in argillaceous (clay-bearing) host rock.

- Crystalline Disposal Research and Development

- Sandia leads R&D to advance the understanding of long-term disposal of SNF and HLW in crystalline (granitic and metamorphic) host rock.

- Salt Disposal Research and Development

- Sandia leads a multidisciplinary, multi-laboratory team of scientists conducting laboratory and field scale R&D examining and quantifying processes associated with the disposal of heat generating waste (i.e., SNF and HLW) in a salt host rock. Sandia, Los Alamos, and Lawrence Berkeley National Laboratories are conducting the Brine Availability Test in Salt (BATS), a horizontal borehole heater test underground at the Waste Isolation Pilot Plant. The goals of this field test are to: improve understanding of brine availability and migration in bedded salt, develop models of the physical and chemical processes that occur in the salt host rock when it is heated, and inform post-closure safety assessment.

- Engineered Barrier Systems (EBS) Research and Development

- Sandia leads R&D to assess feasibility and applicability of EBS concepts in select geological media for the technical challenges specific to the inventory through experimental and computational capabilities that evaluate various disposal concepts and barrier material behavior.

Sandia performs research and development (R&D) to examine the SNF and HLW inventory and the behavior of past, present, and future waste forms and waste packaging concepts associated with geologic disposal. This R&D includes the Online Waste Library (OWL). The purpose of OWL is two-fold. The first purpose is to provide a consolidated single source of information on the many different DOE-managed radioactive wastes that are likely to require deep geologic disposal, such that one can easily query the data. The second purpose is to provide input parameter files with relevant information on waste types, inventory, waste form characteristics, vessels, etc. for performance assessment analyses in the context of the geologic disposal safety assessment (GDSA) framework.

Consideration of borehole disposal for the geologic isolation of spent nuclear fuel (SNF), high-level radioactive waste (HLW), and intermediate-level radioactive waste (ILW) began with U.S. evaluations of nuclear waste disposal options in the late 1950s and continued with intermittent evaluations in several countries. Since 2008, Sandia has performed R&D to advance the understanding of borehole disposal concepts for SNF and HLW. Sandia’s ongoing work supports deep, intermediate, and shallow borehole disposal concepts.

Borehole disposal of radioactive waste has possible economic advantages over mined repository disposal in that drilling, construction, and operating costs scale linearly with waste inventory and the number of required boreholes. As a result, borehole disposal may be particularly attractive for countries with smaller radioactive waste inventories, where the modular cost of a few boreholes may be preferable to the up-front capital investment in a mined repository.

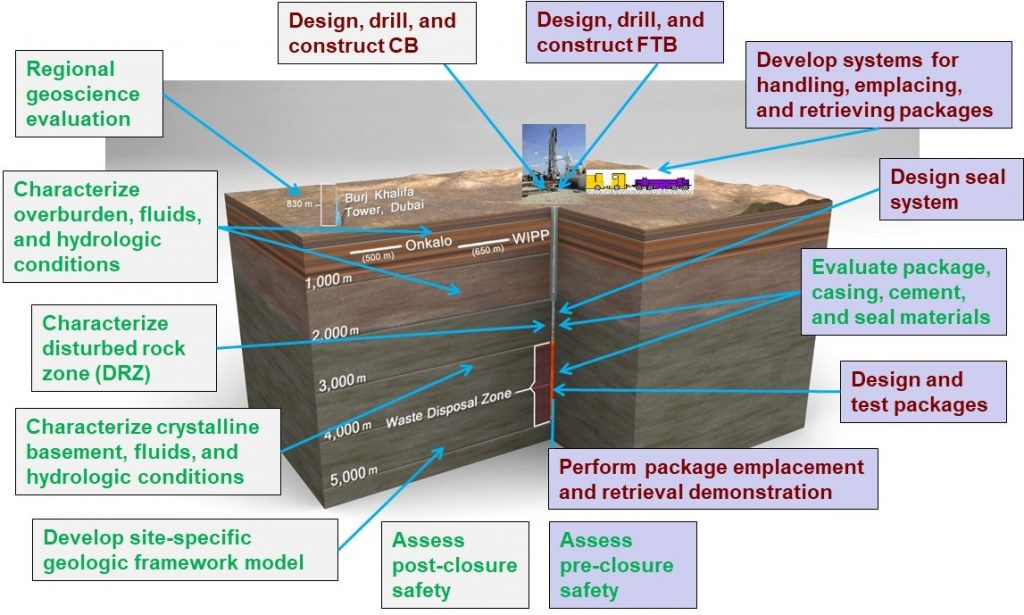

Sandia is a leader in the development of the Deep Borehole concept. The Deep Borehole concept consists of drilling a large-diameter borehole into competent rock (e.g., crystalline basement) to a depth of about 5,000 meters. Waste packages are then placed in the lower waste emplacement zone portion of the borehole and the upper portion is sealed and plugged. Depending on a variety of factors, most notably the size and characteristics of the waste form and packaging, several design alternatives exist that satisfy both the deep and very deep concepts. Waste in a Deep Borehole system is several times deeper than typical mined repositories and is well below the typical maximum depth of fresh groundwater resources.

Depending on the target geologies and waste forms, viable and safe borehole disposal concepts are possible at shallow and intermediate depths over a range of borehole diameters. These concepts range from low-level waste (LLW) and sealed sources in shallow boreholes to intermediate-level waste (ILW) and high-level waste (HLW) in deeper boreholes. For these shallow and intermediate borehole concepts, demonstration of post-closure safety relies on a combination of engineered and natural system performance, much like a mined repository; and the reliance on the engineered seals may be greater than for deep boreholes.

Sandia leads the DOE research efforts to evaluate the technical feasibility of disposing dual-purpose canisters (DPCs) containing commercial SNF in a geologic repository. Strategies for disposal of DPCs include:

- Direct disposal without modification – a disposal licensing strategy that addresses the risk (probability and consequence) from postclosure criticality events

- Modification of already-loaded DPCs with injectable filler material

- Modification of DPCs to be loaded in the future, or the fuel they contain – by changing loading maps, adding disposal criticality control features, or basket redesign.

There are currently approximately 3,000 dual purpose canisters (DPCs) in dry cask storage systems (DCSSs) at nuclear power plants throughout the country storing commercial SNF. In the absence of permanent repository, commercial SNF is expected to continue to accumulate in DPCs, which are designed, licensed and loaded for storage and transportation of commercial SNF, but were not designed for ultimate geologic disposal.

The alternative, repackaging of commercial SNF loaded in DPCs into specialized disposal canisters, would be financially and operationally costly with radiological, operational safety, and management risks. Direct disposal of commercial SNF in DPCs could result in savings of up to $20 billion and would also contribute to better integration between the storage, transportation, and pre-closure disposal operations.

The Sandia-led studies, with contributions from Oak Ridge National Laboratory, have initially concluded that direct disposal is technically feasible for most DPCs, depending on the repository host geology. Ongoing research is investigating:

- Thermal management

- Handling and emplacement operations for the large, heavy packages

- As-loaded DPC criticality modeling (reactivity margin)

- Postclosure criticality consequence analysis

- DPC fillers for criticality control

- Potential future DPC modifications (fuel/basket modification)

Contact

Chris Camphouse

(505) 844-5184

rccamph@sandia.gov

Geoff Freeze

(505) 284-8594

gafreez@sandia.gov

David Sassani

(505) 284-8967

dsassan@sandia.gov

Emily Stein

(505) 845-0706

ergiamb@sandia.gov

Facilities

Sandia maintains chemical and radiological laboratories where experimental work is conducted to support the research and development for many different programs at Sandia National Laboratories. These laboratory facilities include:

The radiochemistry lab is a research facility in which a variety of small-scale, nonproduction chemical, radiochemical, and mechanical activities are performed. The laboratory is primarily used to study radionuclide and other heavy metal environmental remediation methods and technologies. Capabilities include liquid scintillation counting and gamma spectroscopy for radiological analysis. Cement fabrication is also conducted in this laboratory. The non-radiological portion of this laboratory provides bench top space for various tests and houses two fume hoods, EcoMet polisher, sieve shaker, and oven for sample preparation.

The Water Chemistry Laboratory (WCL) and the Analytical Laboratory (AL) are two adjoining labs. The WCL contains generous bench and storage space, as well as, a large fume hood to conduct various synthesis procedures and experiments. The AL houses equipment for analyzing inorganic and organic samples, including a BET surface area analyzer, ion chromatograph, auto titrator, and an inductively coupled plasma- optical emission spectrometry (ICP-OES) instrument. The lab offers ample general chemical storage space as well as standard chemical laboratory equipment (oven, furnace, centrifuge, de-ionized water system, hot/stir plates, sonicator, shaker table, etc.).