The National Solar Thermal Testing Facility excels in the research and development of heat transfer fluids and thermal energy storage systems.

Projects:

Molten Salt Loop Re-Start Project

The Molten Salt Test Loop at Sandia National Laboratories is a unique, industrial-scale testing capability that allows industry, government and academic researchers to test components in flowing, molten nitrate salts. It is one of the only industrial-scale molten salt loops in the world capable of providing 600 oC/ 600 GPM operation with a 1.4 MWth cooling capacity and 6-inch inside diameter pipe size. It is currently in a frozen shut-down state. Significant industry research and development interest exists for having MSTL re-started to de-risk research and development costs across several industries, particularly for Generation 2 and advanced concentrating solar power technologies. Sandia’s team proposes to restart MSTL to provide a testing platform for industry groups to validate large-scale components for use in commercial operation. This project will complete the restart in two phases: 1) complete a high-level forensics evaluation of MSTL while outlining a re-start plan with a Go/No-Go decision, and 2) complete the restart of MSTL for operation in FY25. Current estimated costs for the restart would be significantly less than a new equivalent system.

Contact: Ken Armijo

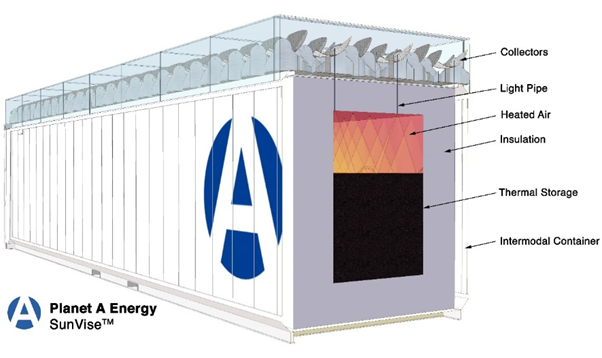

Planet A Energy Project

The U.S. Department of Energy’s Solar Energy Technologies Office awarded Sandia National Laboratories funding to demonstrate a prototype of individual power-added efficiency container components within an integrated system to validate predictions of techno-economic models. The Planet A Energy project will verify the technological and commercial usefulness of a grid-scale solar long-duration energy storage system that can operate either as a stand-alone industrial heat system or with an electrical generator at a concentrating solar power plant. The project will assess techno-economic analysis trade-offs between cost and performance to arrive at an optimum container design that maximizes internal rate of return or other key metrics. Sandia will also complete separate effects tests for the PAE system at the same time to have confidence for an integrated system in the future. This will reduce uncertainties in the optical system, as well as PAE critical thermal processes for storage of sensible heat in a solid particle thermocline energy storage. Following optimization of the system design and establishing the operating conditions for components, the team will perform an integrated system test at process conditions of flow, temperature and pressure, but at a lower power level. PAE will complete its demonstration during the first stage of the project and proceed to develop and validate a higher system during the next stage.

The containers include a set of concentrating solar power solar collectors on top that concentrate up to 750x and deliver heat to the interior of the container where the heat is absorbed in a bed of black sand. The PAE containers are conceived as being able to support 24-hour, seven days a week, year-round energy delivery, as well as intermittent higher-power energy delivery when used as a firming resource. At that duration, each container with 28 m2 can collect and deliver an average of 4.5 kWth continuously, with the state of charge varying seasonally due to an integral of seasonal direct normal irradiance. The exact amount of continuous energy available depends on insulation performance and average length of storage. With very long storage durations, this may drop by as much as 40% depending on insulation. The team will assess optimal insulation employment with respect to cost, overall system size and weight. Higher-power intermittent energy delivery scenarios would potentially show spikes in the state of charge. A single container charged to 800 °C with a 288 °C inlet temperature has a storage capacity of 15 MWhth.

Further support would promote design for a commercial system with sufficient definition to solicit cost quotations from equipment suppliers. Successful prototype demonstration will attract additional investment from public and private sources for a larger pilot-plant, a prerequisite for commercializing the technology. The end-of-project goal is to achieve technology and commercial readiness with a final estimated levelized cost of energy of <$0.07/kWh.

Contact: Ken Armijo

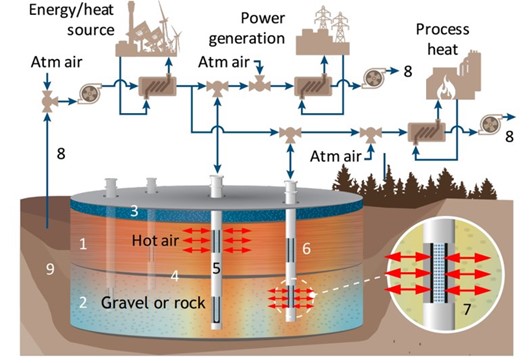

Packed Bed Thermal Energy Storage

Approximately one quarter of the United States’ emissions are generated through the combustion of fossil fuels to create heat. These processes can include pasteurization, drying, roasting and textile manufacturing. When heat is the end use, storing renewable energy as heat can be far cheaper than electrical storage such as batteries. Packed bed thermal energy storage features a bed of gravel that is heated by a stream of renewably heated air. When the thermal energy is required, ambient air is pulled in and heated with the hot gravel. Sandia has worked with local partners to develop a packed bed thermal energy storage test facility. Currently funded projects utilizing the packed bed system include coffee roasting, asphalt heating, and greenhouse heating.

Contact Luke McLaughlin