Digital Thread – Seamless flow of digital information across the product lifecycle that serves as the primary or authoritative source of truth. It encompasses MBSE, MBD, manufacturing data, performance data (from test & surveillance) through design, qualification/certification, validation, production, operational deployment, surveillance, sustainment and dismantlement process.

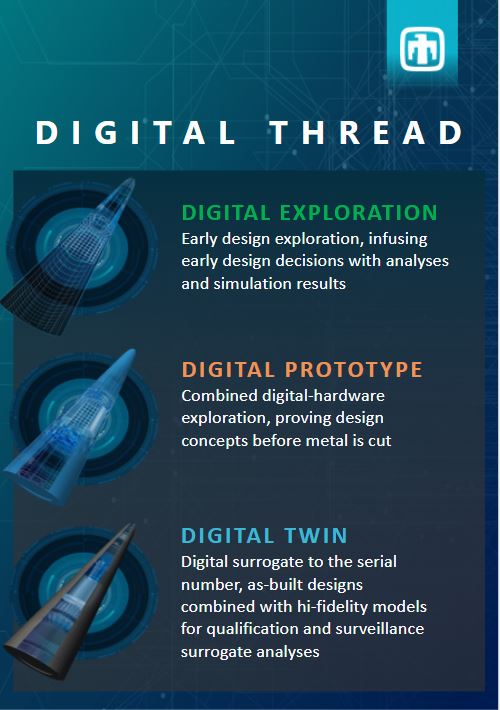

The Digital Engineering Thread is established by taking steps in maturity over three distinct phases. Digital exploration refers to the early design exploration, infusing early design decisions with analyses and simulation results. Digital prototype is combined hardware exploration, providing design concepts before metal or other materials are cut. Finally, a digital twin is reached when a digital surrogate to the serial number, as-built designs combined with hi-fidelity models for qualification and surveillance surrogate analyses.

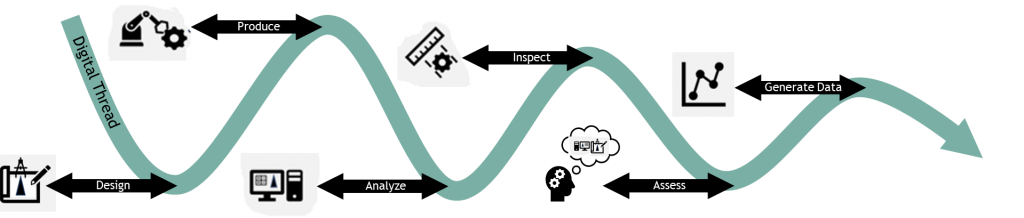

We are focused on establishing a full Digital Thread starting with design and moving through production. This will drive the capability to realize the earliest DE benefits, while laying the foundation for future capabilities.

The journey of the digital thread can be followed by designing, producing, analyzing, inspecting, assessing, and generating data all of which are iterative but not linear in how they are conducted.