The objectives of this work are to:

- assess the effectiveness of computational fluid dynamics (CFD) modeling for evaluating UV disinfection processes,

- determine sensitivity of UV disinfection performance (UV dose response) to parameters, hydraulic configurations, and operational conditions, and

- provide guidance and protocols regarding CFD modeling that will facilitate potential future regulatory acceptance within the context of the USEPA’s UV Disinfection Guidance Manual (UVDGM).

Background

The use of ultraviolet (UV) disinfection for drinking water treatment is expected to increase as a result of the Long-Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) (US EPA, 2006a) and Stage 2 Disinfection/Disinfection Byproducts Rule (US EPA, 2006b).

In order for utilities to receive inactivation credits for UV under the LT2ESWTR, systems must first be validated under the specific design configuration and operating conditions planned for full-scale treatment. Such validation uses costly biodosimetry methods and must be re-done if a utility desires to change their configuration or operation of the UV system.

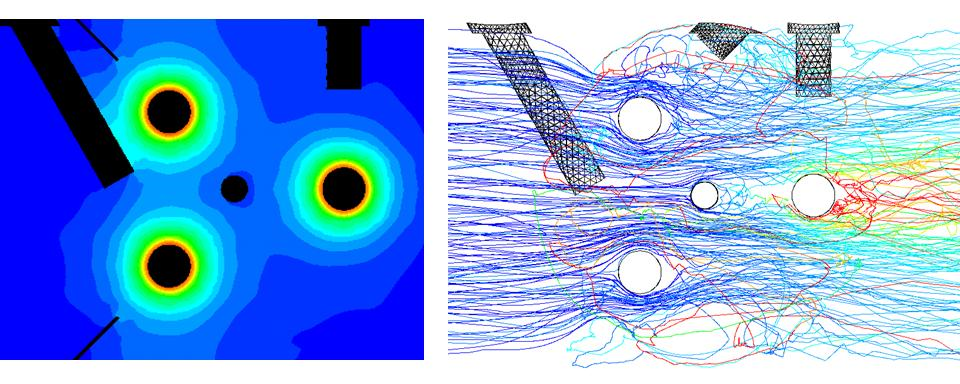

CFD is a modeling tool that has been shown to successfully determine relative differences in UV reactor performance. A CFD model provides detailed information on flow-field characteristics that can aid in identifying hydraulic-based reasons for variations in reactor performance. CFD thus holds promise as an alternative for expensive biodosimetry validation methods and a potential substitute for revalidation.

Reactor design courtesty of Calgon Carbon Corporation.

Research Approach

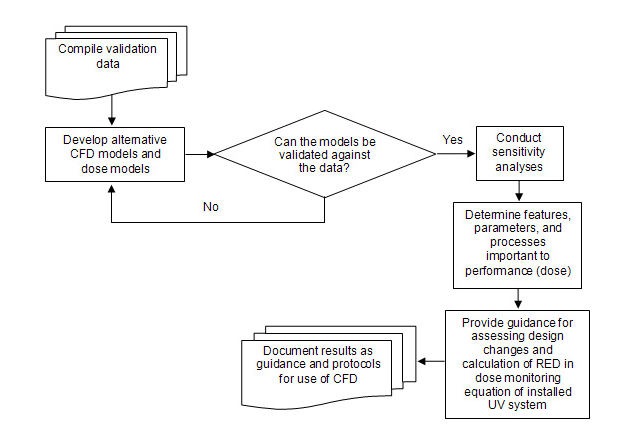

The proposed research consists of the following major activities:

- Compilation of data from UV-reactor validation studies that are suitable for CFD modeling, validation, and assessment

- Development of alternative CFD models and associated models of dose distribution, microbial inactivation, and reduction equivalent dose (RED)

- Conducting sensitivity analyses to identify important features, parameters, and processes that impact performance metrics

- Development of guidance and protocol, consistent with the UVDGM, to use CFD in assessing performance of UV disinfection systems for regulatory acceptance

Flow Chart of Project Activities

Applications Potential

In many cases, utilities will be retrofitting UV systems into existing treatment processes, so they will be limited in their available inlet/outlet configurations and may not be able to achieve optimal configurations. Thus, utilities need a tool to assess hydraulic impacts on UV disinfection performance and evaluate alternative configurations early in the design process. Moreover, a better understanding of the effects of inlet/outlet hydraulic configurations on UV disinfection performance will result in more pragmatic design recommendations, with potential to significantly reduce capital costs in future UV installations.

CFD holds promise as an alternative for expensive biodosimetry validation methods and a potential substitute for revalidation. However, CFD has not yet achieved regulatory acceptance, and the numerous options and approaches for CFD modeling make it nearly impossible to prescribe a universally applicable model and approach for any given site. Therefore, the goal of this project is not to develop a universal CFD model that will be broadly applicable to UV disinfection systems. Rather, the objective of this project is to evaluate the effectiveness of CFD as a tool to assess the impact of design and operational changes on desired performance objectives such as UV dose distribution and the resulting reduction equivalent dose.

Tutorial and Tools

- Tutorial to implement discrete ordinates radiation model in FLUENT

(Word file, 64 KB) - Presentation on implementing discrete ordinates radiation model in FLUENT

(PDF file, 750 KB) - FLUENT UDF to calculate particle dose

(Windows, Serial processor, ZIP file, 64 KB) - FLUENT UDF to calculate particle dose

(Windows, Parallel processor, ZIP file, 120 KB) - FLUENT UDF to calculate particle dose

(Unix, Serial processor, tar file, 72 KB) - FLUENT UDF to calculate particle dose

(Unix, Parallel processor, tar file, 113 KB) - Pre-processor to generate injection points for Fluent

(Windows, ZIP file, 143 KB) - Post-processor and spreadsheet to calculate RED from Fluent output file

(Windows, ZIP file, 1 MB)

References

- Computational Fluid Dynamics Based Models for Assessing UV Reactor Design and Installation, Water Research Foundation Report #4107 (4 MB)