With Additive Manufacturing, often simply referred to as AM or 3D printing, parts are built-up by adding new material in a layer-wise fashion, rather than removing material by machining or similar operations to achieve the final shape. AM is a truly revolutionary technology because it enables entirely new design and manufacturing opportunities that were impractical or even impossible to achieve with traditional manufacturing methods, while also potentially achieving substantial savings in cost and time.

One of the pioneers in AM technology, Sandia began developing additive manufacturing in the 1980s for rapid prototyping of defense and aerospace components. In the mid-1990s, Sandia developed, patented, and successfully commercialized one of the first metal AM technologies, Laser Engineered Net Shaping (LENS). About that same time, Sandia also created and commercialized Robocasting, one of the first AM processes for ceramics.

As the largest Department of Energy National Laboratory, Sandia has decades of expertise and unique capabilities in the design, testing, and manufacture of a wide range of national security and energy related products. Today, Sandia continues to develop new and innovative design, process, and materials technologies to harness the revolutionary potential of additive manufacturing for our unique national security mission. This multi-disciplinary AM technology development effort focuses on three key areas that are core to our mission and where Sandia is uniquely positioned to make strong contributions. These key areas are: Analysis Driven Design, Materials Reliability, and Multi-Material AM.

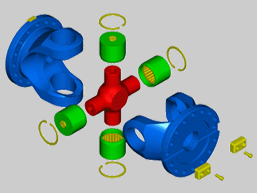

A simple illustration of the difference between a traditional design and an AM enabled design can be seen with a universal joint, a component widely used to transfer rotary motion between two shafts. A traditional universal joint contains dozens of high-precision parts, e.g., needle bearings and races, that must be machined and polished to tight tolerances and then put together in a complex assembly. When used, parts rub against one another creating friction and wear, so it must also be lubricated.

The AM universal joint design provides the same basic functionality as the traditional design, but it is printed as a one-piece, fully-integrated component that doesn’t require high precision machining or complex assembly operations. It also has no moving parts that rub against one another, so it does not require lubricants. It is obviously much faster and cheaper to manufacture the AM design for applications where it can meet service requirements.